Different types of coating rods

Coating rod materials are widely used tools in the Spreader process to control the thickness and uniformity of the Spreader layer. Depending on the structure and use, coating rod materials can be divided into several types: coil-type coating rods, molding coating rods, smooth coating rods, gap-type coating rods, and double-decked coating rods.

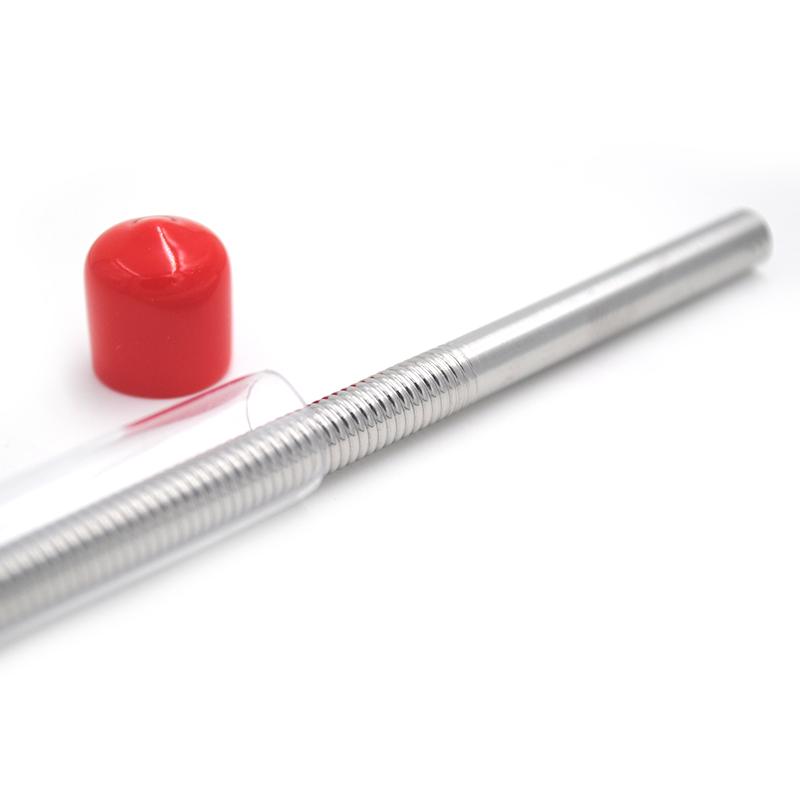

Wire Wound Rods

Coil-type coating rods were introduced early in the 1920s by Charles Mayer and are still a popular type today. Coil-type coating rods range in size from #3 to #75, including many half sizes. Dimensions refer to the coil diameter, measured in thousandths of an inch (.001 inches). Coil-type coating rods can be disbonded and rewound to save costs and reduce waste.

Formed coating rods

The molded coating rod is rolled from a solid steel rod. Appearance is very similar to that of a coiled coating rod. The size of the groove in the molded coating rod determines the coating thickness in the same way as the gap between the coils. However, the radius within the groove of the molded coating rod is less prone to clogging and is easier to clean than a coiled coating rod.

Smooth Rods

Smooth coating rods are commonly used to smooth previously Measured coatings onto paper, Cardboard and Plastic film. The thickness of the coating is controlled by pressure (near the support roll) or film tension. Smooth coating rods can be ground to meet any surface finish requirement, while hard chrome platings can significantly extend the life of the coating rod.

Gapped coating rods

For higher viscosity coatings, gap-type coating rods can reduce clogging and eliminate coating marks. By leaving a gap between the smaller coils (see image), the cavity created is wide and shallow, helping heavy coatings flow more smoothly. Smaller coils create smaller interruptions in the coating flow, making the coating more completely moist. While gap-type coating rods are not as durable as double-decked coating rods, they are more affordable.

Double Wound Rods

For higher viscosity coatings, double-decked coating rods can reduce clogging and eliminate coating marks. By covering a smaller coil over a larger coil (see image), the cavity created is wide and shallow, helping heavy coatings flow more smoothly. The smaller upper coil creates smaller interruptions in the coating flow, making the coating more completely wet. While double-decked coating rods are more expensive than gap-type coating rods, they are also more durable.

Summarize

Different types of coating rod materials have different advantages and characteristics during the Spreader process. Choosing the type of coating rod suitable for a specific application can improve the Spreader effect and reduce blockages and coating marks, resulting in higher mass Spreader results. Whether it is wire-wound coating rods, molding coating rods, Smoothing Rods, gap-type coating rods or double wire-wound coating rods, they are all indispensable and important tools in the field of industrial Spreaders.

- 1Why Do Film Applicators Need to Change Their Wires Regularly?

- 2Mayer-Rod (Mayer Rods) Preparative 2D Copper Nanosheets

- 3The overlooked role of Mayer Rods in laboratory wet-film preparation

- 4Advantages and Categories of Mayer Rods in Spreader wet-film prepative

- 5Mayer Rods: The right-hand man for hiding power tests

- 6How to effectively monitor and extend the service life of coating rods

- 7Application of coating rods on Direct Thermal Label Stock

- 8Types of Mayer Rods and their differences

- 9What are the main differences between Mayer Rods and doctor blade Applicators?