Perovskite Spreader Technology: Preparative Efficient Solar Cell Thin Film

Perovskite coating is used in the preparation of perovskite solar cells. Perovskite solar cells are a new type of solar cell technology that has the characteristics of efficiently converting solar energy into electrical energy. With the rise of renewable energy, the continuous advancement of solar cell technology has become an area of much concern. In this field, perovskite solar cells have attracted widespread interest because of their potential to efficiently convert solar energy into electrical energy. However, one of the keys to preparing high-quality perovskite solar cells is the process of coating perovskite thin films.

Basic principle

A key part of a perovskite solar cell is the perovskite light-absorbing layer, which is usually a thin film that converts sunlight into electricity. Perovskite materials are usually organic-inorganic mixtures with good optoelectronic properties. Coating is the process of uniformly coating perovskite materials on a conductive substrate such as FTO conductive glass or conductive polymer films.

Coating method

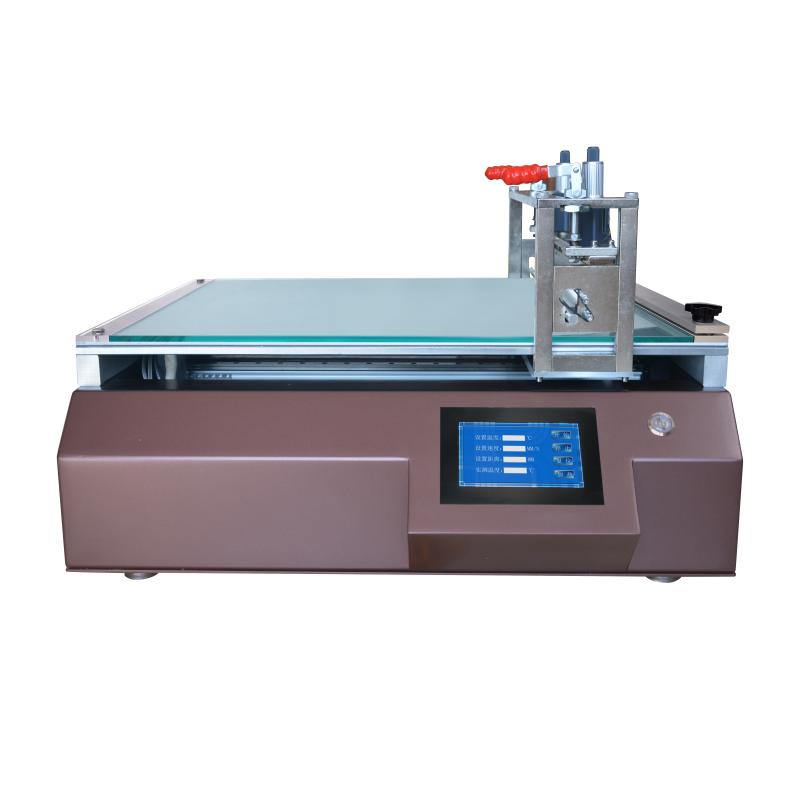

Coating can be carried out using different methods, including spin coating, spray coating, roll coating and scratch coating. Among them, spin coating and scratch coating are common methods. During the spin coating process, a liquid perovskite precursor solution is dropped on the rotating substrate, and the liquid is evenly distributed and formed into a film by the rotational force. In scraping, the researchers used an automatic flat film coating machine with a wire rod scraper for precise film making.

Spreader perovskite films using a metering rod & drawdown blade Film Applicator is a common method of preparing perovskite solar cells. Here are the general steps:

Prepare the substrate

First, prepare a suitable substrate, usually FTO (conductive Glass) or Miscellaneous transparent conductive material. Make sure the surface of the substrate is clean, flat and dust-free.

Preparative perovskite precursor solution

Preparative perovskite precursor solution, which includes perovskite precursor substances, organic solvents, additives and stabilizers. Ensure that the concentration and composition of the precursor solution are correct.

Adjust drawdown blade

Choose a metering rod & drawdown blade of the appropriate width, the width of which determines the thickness of the perovskite film after Spreader. Typically, a wider drawdown blade can be used for thicker coatings, and a narrower drawdown blade for thinner coatings.

Spreader preprocessing

Before Spreader, it is sometimes necessary to apply some processing steps on the substrate, such as pre-coating a layer of titanium ion solution or surface preparation, to enhance the adhesion of perovskite to the substrate.

Spreader

Pour the perovskite precursor solution onto the substrate, then use the metering rod & drawdown blade to homogenize the Spreader. The angle of the drawdown blade and the speed of scraping will affect the uniformity and thickness of the coating. Typically, the smaller the angle of the drawdown blade, the thinner the Spreader. Make sure the Spreader is uniform to avoid bubbles and defects.

Drying

After the Spreader is completed, the substrate is placed to dry at an appropriate temperature to remove the organic components and form a stable perovskite film. Drying conditions often require precise control to ensure the mass of the film.

Add electrode

After completing the perovskite film, an electrode, usually carbon or metal, is added to collect the current.

Testing and performance evaluation

Finally, a series of tests and performance evaluations were performed to determine the performance of the perovskite solar cells, including Linear dispersion measurement of photocurrent-voltage characteristics and long-term stability testing.

Spreader perovskite is a complex process that requires precise control and skill. Therefore, it is recommended to train and practice in a laboratory or professional training environment before performing the actual Spreader. Through precise control of the Spreader process and the prepative of the precursor solution, it is possible to prepare perovskite solar cells with superior performance, which is expected to provide a more competitive solution for the renewable energy field.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body