Hardness of films measured by Paint Coating Authority THIIN-4 (M-3) pendulum

In 1939 the Leningrad branch of the "Paints and Coatings Administration" devised a new and more complete construction of the pendulum Tester.

In 1939 the Leningrad branch of the "Paints and Coatings Administration" devised a new and more complete construction of the pendulum Tester.

The main disadvantage of this instrument is the inconvenience of starting the pendulum, which often distorts the pendulum and produces irreproducible test results.

CB, Yakubovich and TH Vorogushin (TNIIN-4) proposed a simple device for actuating the pendulum, which can completely eliminate the above-mentioned shortcomings. The new "M-3" pendulum Tester is thus specified as the standard pendulum Tester (TOCT5233-50). (Related instrument: pendulum type paint film Hardness Tester)

This one-structure pendulum Tester has been widely used in various laboratories.

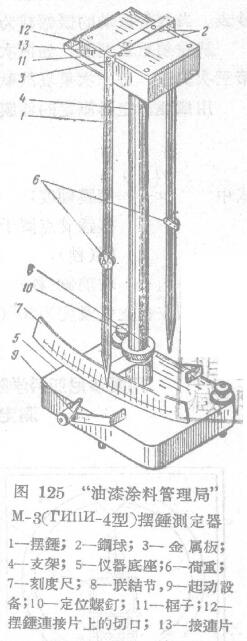

The instrument (Fig. 125) consists of a hammer 1 with two steel balls 2 as fulcrums. Steel ball device is on the metal plate 3 on the support 4. The bracket 4 is fixed on the base 5 . When moving the load 6 on the pendulum, the time for the pendulum amplitude to decrease can be changed.

The pendulum needle moves along the arc-shaped scale 7 engraved with degrees when the pendulum vibrates. The zero degree is engraved in the middle of the scale, and the degrees are engraved from the zero degree opening to both ends. Scale ruler is fixed on the support by coupling joint 8. Starting device 9 is arranged on the instrument base.

The weight of the pendulum is 120 (± 1) grams; the diameter of the steel ball is 8 (+0.0; -0.062) mm; the length of the pendulum from the fulcrum to the tip of the pendulum is 500 (± 1) mm. With the aid of screw 10 and measuring hammer, the base of the instrument can be adjusted to an absolutely horizontal position.

With the aid of frame 11 the pendulum needle is pointing exactly at zero degrees on the scale. The connecting piece 13 of the pendulum is firmly connected to the frame 11 by using two cutouts 12 . In order to avoid the influence of air flow on the scale of the instrument, the instrument should be placed in the glass.

The pendulum should be checked at least once every day and night according to the glass value. The so-called glass value is the time required for the pendulum fulcrum to be supported on the glass and the amplitude of the pendulum to decrease from 5° to 2°. The method of measuring the glass value is the same as the method of measuring the hardness of the tested paint film. The glass value of the pendulum should be 440±6 seconds (that is, within the range of 434~446 seconds). If the glass value is not within the specified range, moving the load 6 up and down can make it just the necessary standard seconds. (Related instrument: Hardness Tester)

Before inspection, carefully wash a glass plate (photographic glass) with a size of 90x120 mm and a thickness of 2 to 3 mm with ether or pure gasoline, and dry it well.

Steel balls must also be checked regularly. If the steel ball is found to be worn or the surface does not meet the requirements of the national standard, a new steel ball should be replaced. Before each test, carefully wipe the steel ball with a cotton ball containing ether or pure gasoline, and then dry it with a clean dry gauze.

Paint the paint sample on a glass plate (photographic glass with a size of 90 x 20 mm and a thickness of 2 to 3 mm).

The method of painting, drying time and method, the number of layers of painting, the thickness of the paint film and the storage time before the test, etc. should be determined according to the regulations or standards of the technical conditions. (Related instrument: drying time Tester)

When the sample is actually dried or after the time specified in the technical conditions, place the paint panel on the plate of the pendulum Tester so that the paint film faces upward. Carefully place the ball of the pendulum in the middle of the plate (not closer than 2 cm from the edge of the plate) so that the pendulum needle points near zero degrees on the scale. Then, lift the super frame, stick the connecting piece on it and make the pendulum aim at zero degree. After that, without putting down the scorpion and keeping the connecting plate still.

Use the super-motion device to carefully guide the pendulum needle to the left by 5°. (This is necessary to keep the steel ball from moving). Put down the frame and press the button of the starter device to release the swing needle leading to the left; at the same time start the stopwatch. Stop the stopwatch when the amplitude of the needle vibration decreases to 2°.

The test must be repeated twice. If the difference between the two test results is greater than 3%, a third test should be carried out. Each repeated test shall be carried out on a new place on the paint film.

The hardness of the paint film measured by the pendulum Tester can be calculated by the following formula:

- 1Determination of paint film hardness by pencil method under GB/T 6739 standard

- 2How much do you know about the 3 methods of paint film hardness testing?

- 3Determination method of paint film hardness - swing rod hardness, scratch hardness, indentation hardness

- 4Determination of Hardness of Waterborne Anticorrosive Coating film

- 5Effect of Ultraviolet curing paint Spreader on Wooden ground floor film performance

孙伟圣;王艳伟;徐 立;杨植辉;张秋娟;晁 久;吴忠其;李先春 - 《木材工业》

- 6Film Swing Hardness Test

郑顺兴 - 《涂料与涂装科学技术基础》

- 7Film Scratch Hardness Test

郑顺兴 - 《涂料与涂装科学技术基础》

- 8Film Indentation Hardness Test

郑顺兴 - 《涂料与涂装科学技术基础》

- 9What are the classifications of commonly used Hardness testing instruments?

-

JINGQI WD8220 Hardness Tester$ 485.00

-

-

-

-

-