Coating product performance testing: Appearance color non-volatile matter viscosity, fineness and storage stability

Coatings play an important role in a variety of Applications, whether in construction, automotive manufacturing or industrial processing. In order to ensure the mass and performance of Coatings, Coating product performance testing is an indispensable step. This article will discuss in detail all aspects of Coating product performance testing, including Appearance and transparency, Color, Coating Density, non-volatile matter, Coating viscosity, Coating fineness, and Coating storage stability.

1. Coating Appearance and transparency

Appearance and transparency of Coatings are one of the basic signs of Coating mass. Appearance determination involves placing a sample in a Colorimetric tube to see if it contains mechanical impurities at a specific temperature. Transparency determination evaluates transparency levels by comparing the sample's performance under transmitted light with the turbidity of the standard solution. These test methods help determine whether Coatings meet mass standards, especially for products such as varnishes, oils and paints.

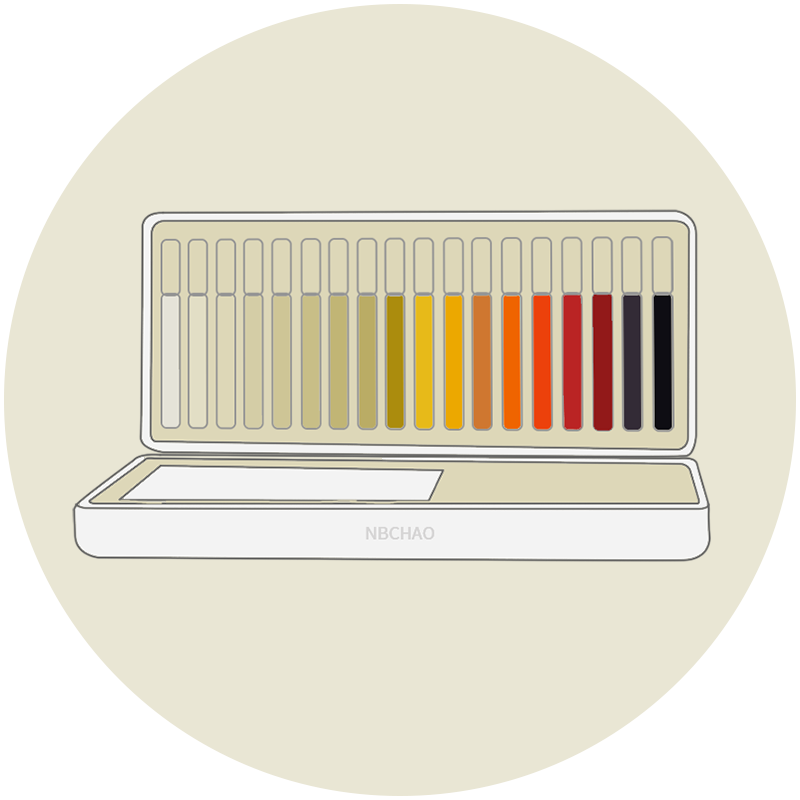

2. Color

Color is another key factor in the performance of Coating products. The Color of Coatings not only affects aesthetics, but can also play a role in marking and decoration in some applications. The standard specifies methods for determining varnishes, clear oils and thinner Color, usually using iron drill Colorimeter or Formula Guide for visual comparison. In some cases, in order to reduce subjective errors, instruments such as photoelectric color readers can also be used for quantitative determination.

3. non-volatile matter

Non-volatile matter is the active ingredient in Coating, and its content reflects the mass of Coating. The higher the non-volatile-matter content, the more active ingredients in Coating, which is an important quality control parameter in Coating production. The method of determining non-volatile matter involves heating the sample under specific conditions, and then calculating the non-volatile-matter content by weighing the mass change before and after the sample. However, this method cannot accurately determine non-volatile matter such as trace amounts of water vapor, which may lead to deviation of the results.

4. Coating viscosity

The viscosity of a Coating is one of its physical and chemical properties, which reflects the molecular weight and directly affects the performance of the Coating. Too high viscosity will make the Coating difficult to use, and too low viscosity will easily lead to problems such as sag. The determination method of viscosity is usually specified in the specification to ensure conformity and accuracy.

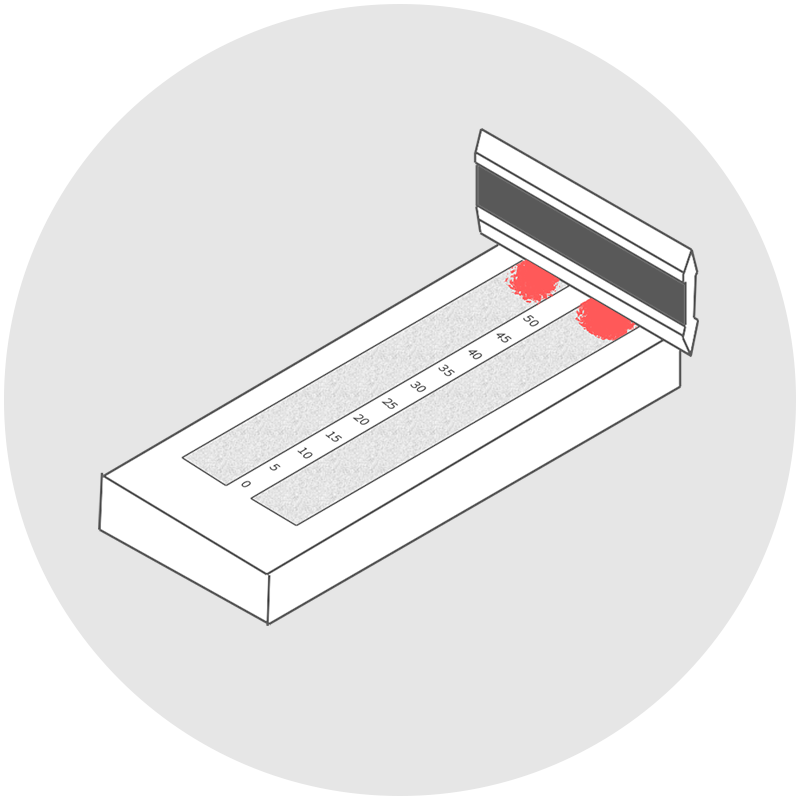

5. Coating fineness

Coating fineness detection is mainly used to check the size of pigment, extender and other particles or the uniformity of dispersion, usually expressed in microns. Fineness directly affects the Gloss, water permeability and storage stability of Coatings. By measuring the size and distribution of particles, we can better understand the performance characteristics of Coatings.

6. Coating stability

Coatings storage stability testing is a key step in evaluating changes in Coatings performance during storage. Tests include measurements of viscosity changes, pigment sedimentation, ease of remixing, and changes in Miscellaneous performance parameters. These tests can be performed under different environment conditions to simulate what Coatings may encounter in actual use. Stability testing helps ensure that Coatings maintain their performance unaffected during storage and transportation.

To sum up, Coating product performance testing is a key step to ensure Coating mass and performance. The determination methods of various Coating performance parameters are specified in detail in national standards to ensure the accuracy and comparability of results. Through strict performance testing, Coating can be guaranteed to perform well in various Applications and meet customer needs and standard requirements. Therefore, professionals in the field of Coating production and use must fully understand and abide by these performance testing standards to ensure Coating mass and Reliability.