How to measure Coating varnishes Density with Specific Gravity Bottles

Coatings and varnishes are indispensable materials in various Applications, and their Density is one of the important parameters for evaluating their mass and performance. This article will describe how to use the Specific Gravity Bottle to measure the Density of Coatings and varnishes, including the scope of application, required instruments and materials, and detailed measurement procedures.

1. Scope and description

Density refers to the mass of a unit volume of liquid at a specified temperature, usually expressed in g/ml. This method is suitable for measuring the Density of liquid Coatings, varnishes and other products at a specified temperature. The principle is to use the Density of distillation water to calibrate the volume of the Specific Gravity Bottle, and then measure the mass of the sample at a certain temperature through the Specific Gravity Bottle to calculate the Density of the sample.

2. Instruments and materials

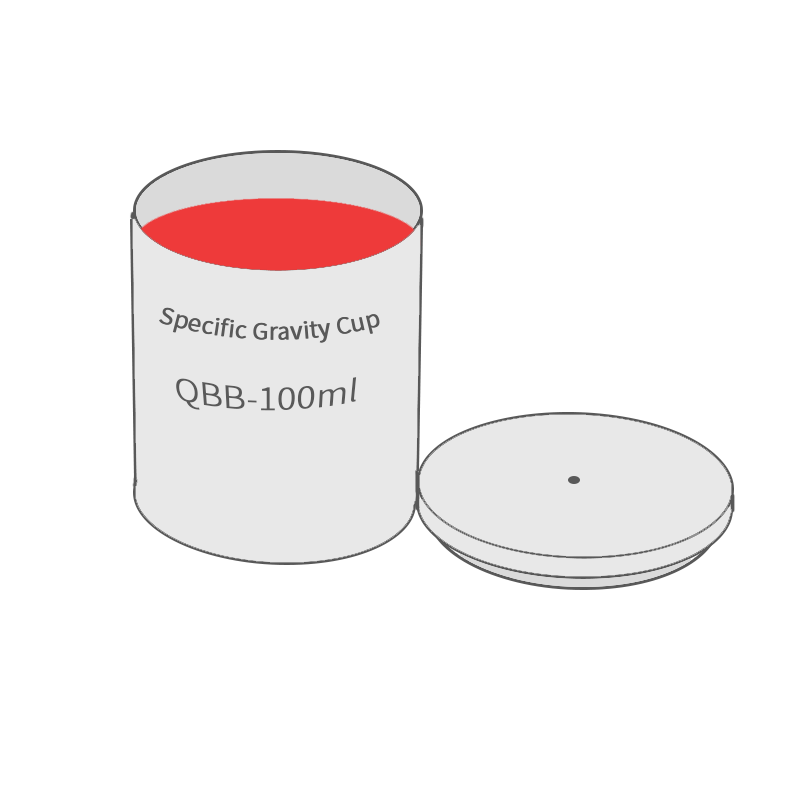

Specific Gravity Bottles: Usually available in different capacities such as 37ml, 50ml and 100ml, made of stainless steel or aluminum alloy.

Thermometer: accuracy to 0.2 ℃, usually graded to 0.1 ℃.

Thermostatic Water Bath or thermostatic chamber: It is required to be able to maintain within +/- 0.5 ℃ of the test temperature, or higher accuracy is required to be within the range of +/- 0.2 ℃.

Analytical Balance: accuracy to 0.2 mg.

3. Determination method

Specific Gravity Bottle calibrated:

Use a clean, drying Specific Gravity Bottle and weigh at room temperature.

Clean, dry and weigh the Specific Gravity Bottle continuously until the difference between two successive weighings does not exceed 0.5 mg.

At the test temperature (usually 23 +/- 2 ℃, or - 0.5 ℃ for higher accuracy), fill Specific Gravity Bottle distillation water to ensure no bubbles.

Place the Specific Gravity Bottle in a thermostatic bath or thermostatic chamber until the temperature is constant. During this process, make sure that no water droplets remain on the surface of the Specific Gravity Bottle.

Immediately weigh the Specific Gravity Bottle filled with distillation water to 0.001% accuracy.

Calculation of Specific Gravity Bottle Volume:

Calculate the volume of the Specific Gravity Bottle (expressed in ml) using the following formula:

V = (m1 - m0)/V

Of which:

V is the volume (ml) of the Specific Gravity Bottle.

M1 is the mass (g) of the Specific Gravity Bottle filled with distillation water.

M0 is the mass (g) of the drying Specific Gravity Bottle.

P is the Density of distillation water (usually 1 g/ml).

Determination of Product Density:

Using a sample instead of distillation water repeability of the above steps.

When operating, wear analytical gloves to avoid direct contact with the Specific Gravity Bottle.

When injecting specimens into the Specific Gravity Bottle, be careful to avoid bubbles and ensure that the Specific Gravity Bottle is externally clean to ensure accurate weighing.

4. Presentation of results

Calculate the Density of the product at the test temperature T (usually 23 ℃ or Miscellaneous agreed temperature) according to the following formula, expressed in g/ml:

Density = sample mass/sample volume

5. Conclusion

Measurement of the Density of Coatings and varnishes is an important step in ensuring their mass and performance. By using Specific Gravity Bottles and appropriate instrumentation, accurate measurement of the Density of the product can help manufacturers and users assess its suitability and mass. Density data is very important for production control and quality control, so the correct choice of Measuring methods and instrumentation is crucial. Through Density measurement, the physical properties of Coatings and varnishes can be better understood to support their applications.

- 1Specific Gravity bottle Density Error

- 2How to evaluate the defoaming performance of defoamer by high-speed stirring test method?

- 3Determination of Coating Density: Density Cup

- 4What is mass?

- 5How to calibrate Density Cups? How to measure Density

- 6Determination of Coating Density

- 7Introduction to ISO8130-2:1992 "Determination of Density by Gas Comparison Ratio Method (Arbitration Law) "

- 8Coating liquid performance inspection -- paint and Varnish Density Determination

- 9Error Analysis and Comparison of Lee's Specific Gravity Bottle Method and Gan's Specific Gravity Bottle Method in Powder Density Measurement

徐建民; 徐建成 - 《测量粉末密度的两种比重瓶法误差的分析和对比》