How to use the Coat-4 cup Viscometer for Coating viscosity measurement

Coating viscosity is one of the key indicators for evaluating Coating flowability and coating performance. The Coating-4 cup Viscometer is a commonly used instrument for the measurement of Coating viscosity. This article will describe how to use the Coating-4 cup Viscometer to measure Coating viscosity, including methods, instruments and result representation.

1. Scope and description

This method is suitable for measuring the viscosity of Coatings using the Coat-4 Viscometer. Coat-4 Viscometer is suitable for measuring Coatings with an outflow time of less than 150 seconds, including Coating work in progress and related products. The measured viscosity is the conditional viscosity, which is the time it takes for a certain amount of sample to flow out of a specified hole at a certain temperature, expressed in seconds (s).

2. Instruments and materials

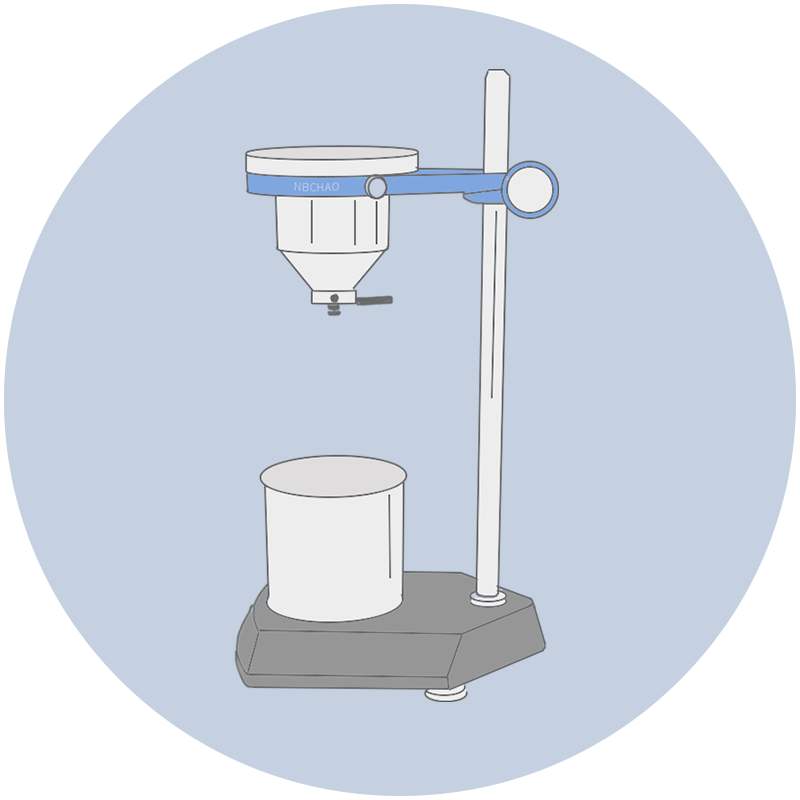

Coat -4 Viscometer

Thermometer: temperature range 0~ 50 ℃, the division is 0.1 ℃ or 0.5 ℃.

Stopwatch: The division is 0.2 seconds.

Bearing cup: an enamel cup with a volume of 150 ml.

3. Determination method

(1) Instrument preparation

Thoroughly clean and dry the 4 Viscometer, including parts such as the Viscometer spill, before performing the assay. Wipe the Viscometer with gauze dipped in a solvent and make sure it is drying. Check the spill and Optical inspection parts of the Viscometer to make sure they are kept clean.

(2) Preparation of samples

The Coating to be tested is fully stirred, and then the temperature of the sample is adjusted to (23 +/- 1) ℃ or (25 +/- 1) ℃.

(3) Carry out the measurement

Adjust the Viscometer to keep it level and place a 150ml enamel cup under the Viscometer spill.

Plug the leak with your finger and pour the sample into the Viscometer at (23 +/- 1) ℃ or (25 +/- 1) ℃.

Use a Glass Rod or Glass Plate to scrape bubbles and excess specimens into grooves coated with -4 cups.

Quickly remove your finger and start the stopwatch at the same time. Stop the stopwatch immediately after waiting for the sample flow to be completely interrupted. The stopwatch reading is the sample flow time (s).

4. Presentation of results

Take the average value of the two measurements as the measurement result. The difference between the two measurements should not exceed 3% of the average value. The outflow time (seconds) of a coating-4 cup Viscometer can be converted to a kinematic viscosity value (cm ^ 2/sec) using the following formula.

5. Reference standard

When measuring the coating-4 cup Viscometer, you can refer to the national standard GB/T 1723 "Coating Viscosity Determination Method".

Coating-4 cup Viscometer is a commonly used Coating viscosity measurement tool that quickly and accurately evaluates the viscosity characteristics of Coatings. By following the above measurement method, Coating manufacturers and users can better understand Coating performance and ensure its performance in different applications. This method is suitable for viscosity measurement of a wide range of Coatings and Coatings work in progress.

- 1Discussion on the calibration method of coating-4 viscosity cup

- 2Tu-4 cup viscosity test steps, instruments and usage

- 3Viscosity cup introduction and selection guide

- 4Determination Method of Viscometer and Its Application in Coating

- 5The calibration method of 4 viscosity cup

- 6What are the test subjects for perchlorovinyl resin anti-corrosion coatings?

- 7What are the differences between the four domestic desktop copper-coated -4 viscosity cups?

- 8Coated 4 viscosity cup - this one is really affordable!

- 9What is dip coating? How to dip coating?