Determination method of paint film scrubbing resistance and its importance

Introduction

Coatings or paint films play an important role in architecture, industry and everyday life. However, paint films can be damaged by contaminants for various reasons, such as Coating in easily soiled areas such as doors and windows. In order to ensure that paint films can withstand multiple washes without losing their function and Appearance, it is necessary to determine the wash resistance of paint films. This article will introduce the definition of paint film wash resistance, test methods, related standards and the importance of this test method.

1. Definition, purpose and meaning

Film scrubbing resistance refers to the relative abrasion resistance of coatings when they are subjected to multiple washes to remove contaminants during use. For architectural coatings, especially close to doors and windows and other easily contaminated parts, multiple washes are often required, so scrubbing resistance becomes one of the important assessment indicators for these coatings.

2. Relevant standards

In order to accurately measure the scrubbing resistance of paint films, the national standard GB/T 9266 has formulated a set of standard test methods for evaluating the scrubbing resistance performance of paint films. This standard specifies the test principle, required equipment, operation points, and result representation to ensure test Reliability and repeatability.

3. Introduction of inspection methods

3.1 Testing principle

The principle of the paint film scrubbing resistance test is to wash the paint film with a certain load of the mane brush under the condition of constantly adding detergent, and observe the number of times of washing when the surface of the paint film is just exposed or the number of times of washing to the specified number of times. Whether the coating is damaged. This test principle is based on the performance of the paint film after multiple washes.

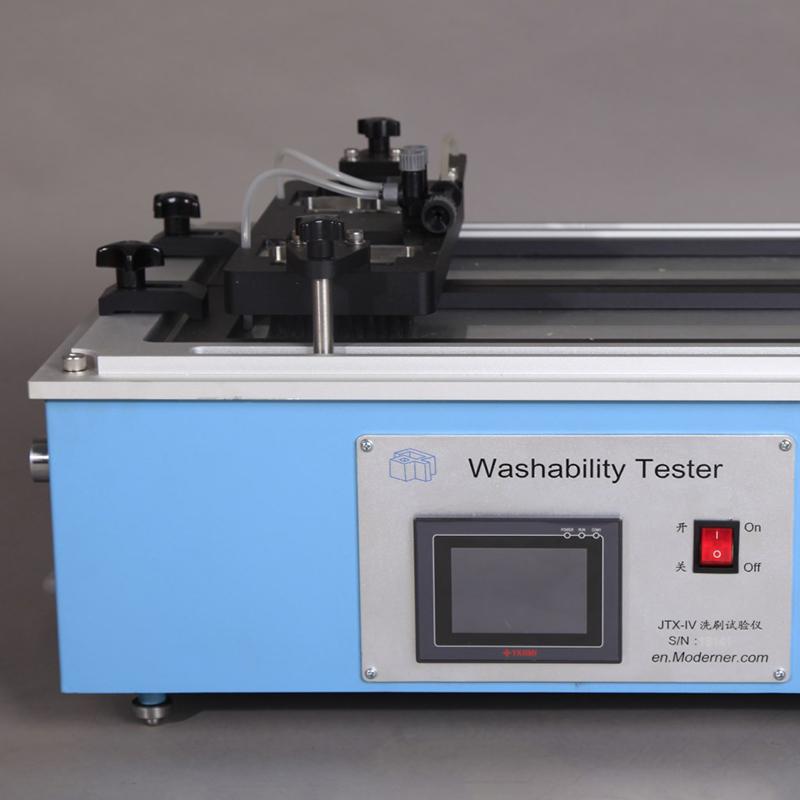

3.2 Introduction to the instrument

The paint film scrubbing resistance test requires the use of a paint film scrubbing resistance Tester, which has the following characteristics:

The total weight of the brush and fixture is 450 grams.

Frequency of brush reciprocation is 37 times per minute.

The brush moves 300 mm in each stroke and moves at a constant speed in the middle 100 mm interval.

Glass panels, cement asbestos panels or samples of agreed Miscellaneous materials are also required, which should measure 430mm x 150mm x 3mm.

3.3 Operation points

Before the test, it is necessary to treat the brush, immerse it in water 12 mm deep for about 30 minutes, then throw the clean water, and then immerse it in the washing medium (0.5% washing powder solution, pH 9.5~ 10.0) 12 mm deep for 20 minutes. Only brushes after such treatment can be used. During the test, the sample is fixed, the brush is placed on it, the coating is rubbed back and forth, and the washing medium is added dropwise until the washing reaches the specified number of times or the coating exposes the substrate in the middle 100 mm area. Finally, remove the sample and wash it with tap water.

3.4 Presentation of results

Depending on the test results, the scrubbing resistance of the paint film can be expressed by the number of scrubbing times the sample is subjected to when it is just exposed. Alternatively, if the films of at least two of the three test plates are not damaged after the specified number of scrubbing, the scrubbing resistance of the paint film is considered qualified.

Conclusion

Film scrubbing resistance testing is an important method for measuring coating performance, which ensures that coatings can maintain their Appearance and function after multiple washes. This is important for coatings in construction, industry and daily life, as they often need to undergo multiple cleanings and washes. By following relevant standards and test methods, the scrubbing resistance of paint films can be effectively assessed, providing strong support for the selection and application of coatings. Therefore, understanding the scrubbing resistance of paint films is of great significance for the Coatings and varnishes industry.

- 1Test the scrubbing resistance of paint film with scrubbing Tester

- 2Testing of conventional properties of waterborne coatings and coatings

- 3Construction characteristics and skills of deck paint

- 4How is film washability measured?

- 5How to determine the washability of Architectural coatings coating?

- 6Main technical indicators of exterior wall emulsion paint testing

- 7[Special topic of film performance and measurement knowledge] - Determination of film washability