Precise determination of conductivity of pigment water suspension and its importance in industrial application

Pigments play a central role in a number of industrial fields. From paints for everyday use to coatings for high-end electronics, the use of pigments is involved. However, for some applications, understanding the physicochemical properties of pigments is not only necessary, but also key to ensure the quality and performance of products. This paper mainly discusses the methods for determining the conductivity of pigment aqueous suspensions and explores in depth its importance in practical industrial applications.

The Scientific Basis of Pigment Conductivity Determination

Conductivity is the ability of a substance to conduct current at a certain temperature. For pigment aqueous suspensions, its conductivity is mainly affected by the ion concentration of the suspended pigment particles as well as the medium (such as pure water or methanol). By measuring conductivity, we can indirectly obtain information about the pigment ion release properties, which is essential for some special applications.

Technical details of conductivity measurement

Water wettability of pigments: The wettability of pigments affects their dispersibility in water, which in turn affects the accuracy of the measurement. Therefore, it is first necessary to determine whether the pigment is easily wetted by water.

Treatment of hydrophilic pigments: For pigments that have a good affinity for water, they need to be mixed with boiled pure water first, then cooled and filtrated for subsequent conductivity determination.

Treatment of hydrophobic pigments: These pigments require wetting treatment with methanol before adding pure water to form a uniform slurry, followed by similar cooling and filtrate treatment.

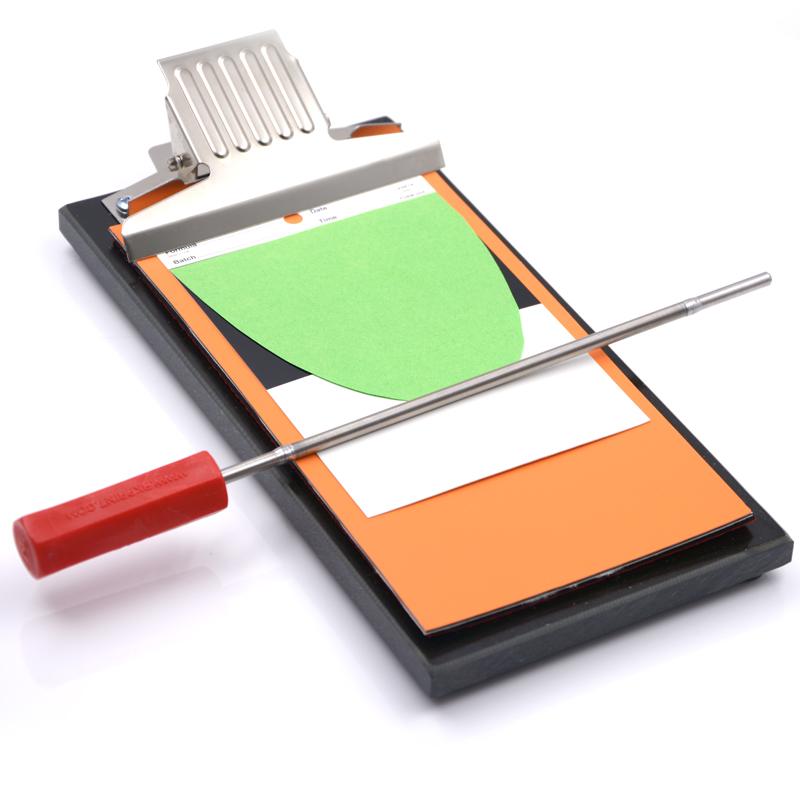

Conductivity measurement is performed using high-precision conductivity meters and specialized conductivity electrodes to ensure the accuracy and reliability of the data.

The practical importance of industrial applications

Preparation of conductive coatings: When preparing conductive coatings, the conductivity of the pigment directly affects the conductivity of the final product. Accurate conductivity data can help manufacturers optimize their formulations to achieve the desired conductivity.

Protective coatings for electronic equipment: High-performance electronic equipment may require special coatings to prevent electromagnetic interference or electrostatic accumulation. The conductivity of such coatings needs to be within a specific range, so accurate data on the conductivity of pigments is essential.

Quality control: For pigment manufacturers, conductivity measurement can be used as an important quality control tool to ensure product consistency and performance standards.

Conclusion

Conductivity measurement of pigment water suspensions is not only a basic technology in chemical and physical research, but also plays an irreplaceable role in practical industrial applications. With the development of new materials and advanced technologies, the demand for pigment conductivity data will continue to grow, emphasizing the importance of this measurement technology in the future.