Introduction to Measurement Method of Film Impact Hardness

1. Determination of impact hardness of coating film

The impact hardness test of the coating film can also be carried out on the y-1 instrument. In this case, on top of the iron plate and under the test plate, another steel plate with a considerable thickness needs to be placed to prevent the paint film from stretching (elongation).

Another simple instrument for determining the impact hardness of coating films9 is shown in Figure 148. Ball traces appear on the surface of the plate after the impact, and its diameter can be measured in the same way as in the hardness static test by the indentation method. (Related instrument: Hardness Tester)

The specific hardness or unit deformation function can be calculated by the kilogram/mm2 number on the surface of the coating film.

Second, use the "repeated impact" method to determine the impact hardness of the coating film

The principle of this measurement method is to make the paint film on the bottom plate be repeatedly impacted by steel balls until the paint film begins to be damaged. (Related instrument: impact Tester)

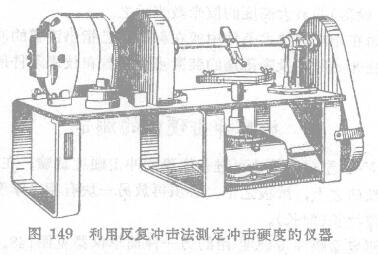

Document 9 describes an apparatus for measuring the strength of a coating film by the "repeated impact method". Such an instrument is shown in Figure 149.

The test procedure is as follows. Fix the varnished or painted test plate on the flat base of the instrument, and then subject it to repeated impacts of surface-hardened steel balls; the steel balls are fixed on the short handle, and the short handle is fixed on the rotating long on the handle. The long handle is driven by a synchronous motor with 150 to 350 revolutions per minute.

The impact strength is determined by the number of steel ball impacts required for the paint film (varnish or paint) to start to damage. During the test and at the moment when the paint film is effectively damaged, it is necessary to use a microscope with a small magnification to observe the surface state of the tested paint film. The paint film can be irradiated with electric lamps during the test. The coated test panels need to be flat; otherwise the panels may be elastic and completely inaccurate results will be obtained. The rotation speed of the instrument is adjusted according to the impact strength of the coating film.

There is a special device in the instrument, and the test plate coated with the sample can also rotate by itself, thus increasing the impacted area of the paint film.

- 1Determination of paint film hardness by pencil method under GB/T 6739 standard

- 2How much do you know about the 3 methods of paint film hardness testing?

- 3Briefly describe how different industries view product packaging

- 44 test types for measurement of coating strength

- 5What performance subjects are tested for water-based floor coating materials and how do they meet the standards?

- 6What are the testing performance requirements for different substrates of epoxy resin primer?

- 7Performance index of medium paint for railway vehicles

- 8Marine coating testing instrument selection plan

- 9Determination method of paint film hardness - swing rod hardness, scratch hardness, indentation hardness

-

-

-

-

JINGQI WD8220 Hardness Tester$ 481.00

-

-