Epoxy-polyethylene (PE) Resin thick coatings Anticorrosive coatings: innovative protection solutions

Epoxy-polyethylene resin thick-coat heavy-duty anti-corrosion coatings: innovative protective solutions

Aerogel, commonly known as "freeze smoke", is a special material made by extracting the water from silica gel and then replacing the water with a gas (such as carbon dioxide, etc.). This substance has excellent insulating properties while adsorbing contaminants such as crude oil. There are a large number of tiny pores inside the airgel. The typical pore size is between 1 and 10 microns, and the porosity is as high as more than 80%, which makes it a material with a nanoscale porous structure.

Preparation:

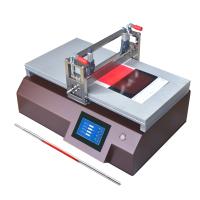

The process of preparing thick coats of epoxy-polyethylene resin for heavy-duty anti-corrosion coatings is relatively simple. First, accurately weigh the bisphenol epoxy resin and diluent into a mixing tank and stir thoroughly to completely dissolve it into a uniform and transparent resin liquid. Next, part of the resin liquid is taken out and mixed together with the pigments and fillers, and the mixture is then ground through a three-roller mill to the desired particle size. Finally, add the remaining resin liquid, stir evenly, then filter and package.

Construction method:

The paint is applied using air spraying. During this process, an air pump needs to be used to mix the compressed air with the paint, usually the compression ratio is 1:45, and the pressure of the atomized air is between 0.4~0.5MPa. On vertical surfaces, a coating film with a thickness of up to 10 mm can be applied, and this coating film can usually be cured at room temperature or low temperature.

Application scope:

This thick-coat heavy-duty anti-corrosion coating of epoxy-polyethylene resin has good mechanical properties, especially at low temperatures. It also performs well in extremely harsh environments and has excellent anti-corrosion properties. In addition, the coating film of this coating cures at room temperature or low temperature and can maintain toughness and softness over a wide temperature range. It is suitable for various application fields such as component equipment and marine buildings.

In summary, epoxy-polyethylene resin thick-coat heavy-duty anti-corrosion coatings represent an innovative protective solution that provides reliable corrosion protection for a variety of engineering projects and is expected to continue to play an important role in the future. As technology continues to advance, we can expect more new anti-corrosion coatings to emerge to address changing engineering and environmental needs.