Anti-corrosion coatings: guardians of metal erosion

Anticorrosive coatings are an essential class of coatings designed to protect metals and other materials from corrosion and erosion. According to different needs and usage environments, anti-corrosion coatings are divided into conventional anti-corrosion coatings and heavy-duty anti-corrosion coatings. Both types of coatings play a vital role in extending the life of materials and maintaining infrastructure.

Conventional anti-corrosion coatings :

Under normal circumstances, conventional anti-corrosion coatings are sufficient to provide corrosion protection to materials such as metals, thereby extending their service life. These coatings show good results in general corrosive environments, but under more harsh conditions, such as chemical atmospheres and marine environments, more powerful anti-corrosion protection measures are required. At this time, the use of heavy-duty anti-corrosion coatings must be considered.

Characteristics of heavy-duty anti-corrosion coatings :

Heavy-duty anti-corrosion coatings have the following characteristics:

Long anti-corrosion life

Heavy-duty anti-corrosion coatings are capable of being used in harsh conditions and provide long-term anti-corrosion protection life. In the chemical atmosphere and marine environment, the service life of heavy-duty anti-corrosion coatings can reach 10 or 15 years, and it can maintain effectiveness for more than 5 years even in acid, alkali, salt and solvent media.

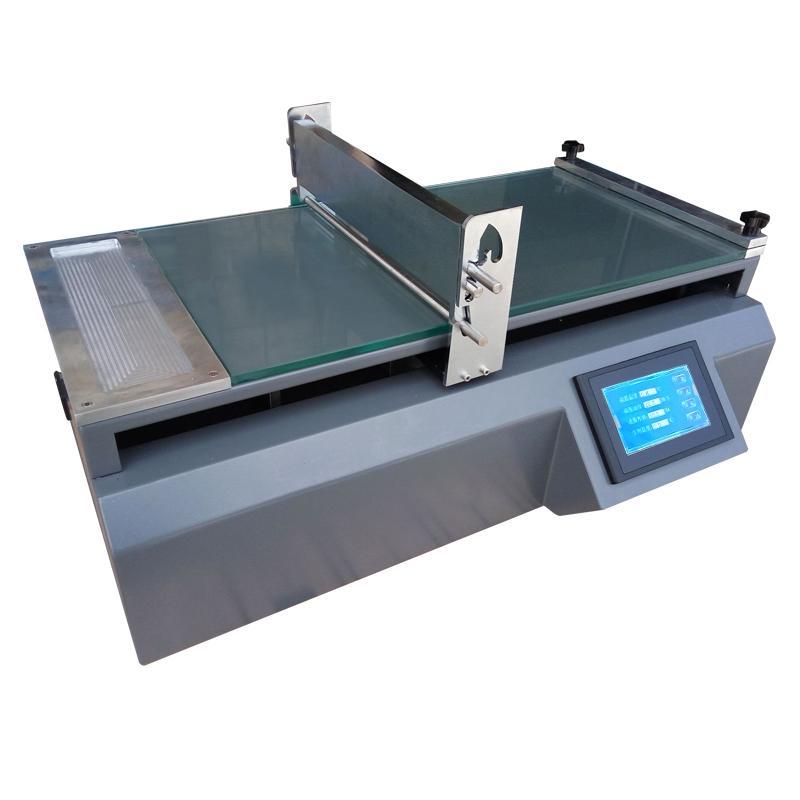

Thick film

Thick film is an important sign of heavy-duty anti-corrosion coatings. The dry film thickness of general anti-corrosion coatings is about 100 μm or 150 μm, while the dry film thickness of heavy-duty anti-corrosion coatings is usually above 200 μm or 300 μm, and can even reach 500 μm to 1000 μm, or even as high as 2000 μm. This property allows heavy-duty anti-corrosion coatings to provide a stronger layer of protection against corrosion and erosion.

The development history of anti-corrosion coatings :

The development of anti-corrosion coatings can be traced back to the Industrial Revolution. In the 19th century, linseed oil red paint and white enamel paint were first used in machinery, trains, ships, motors and other fields. After World War I, nitrocellulose rope appeared to meet the rapid drying needs of automobile assembly lines, and painting tools gradually developed into Spray Guns. In the 1930s, alkyd enamels emerged as a new type of paint that had excellent weather resistance and could be used for outdoor construction and automotive drying paints. In the 1960s, the development of epoxy and polyurethane resins significantly improved the performance of anticorrosive coatings. Epoxy resin anticorrosive coatings and polyurethane anticorrosive coatings have begun to be widely used in various fields. In the 1970s, the emergence of cathodic electrodeposition paint caused major changes in product primers on the assembly line. In the 1980s, cathodic electrodeposition paint began to be widely used in automobile manufacturing and home appliance production. Over time, new coatings such as aliphatic polyurethane paints, powder coatings, water-based coatings and high-solid coatings have emerged one after another to meet the increasing demand for anti-corrosion coating performance in different fields.

Application areas of anti-corrosion coatings :

Anti-corrosion coatings are widely used in various fields, including but not limited to:

Plumbing facilities

Including gas pipelines, natural gas pipelines, drinking water facilities, etc.

energy facilities

Used in hydraulic equipment, Water Tanks, petroleum refining equipment, petroleum storage equipment (such as oil pipes and oil tanks), power transmission and transformation equipment, nuclear power plants and coal mines, etc.

road traffic

Covering highway guardrails, bridges, ships, containers, trains, airport facilities, etc.

large industrial facilities

Used in pulping equipment, pharmaceutical equipment, food and chemical equipment, inner and outer walls of metal containers, pipes and storage tanks in chemical, steel, petrochemical plants, mining smelting, cement plant equipment, floors with corrosive media, wall cement components, etc.

Marine engineering facilities

Including offshore facilities, coastal and bay structures, offshore oil platforms, etc.

The role of anti-rust pigments :

Anti-rust pigments in anti-corrosion coatings play a key role in achieving anti-corrosion protection. The mechanism of action of anti-rust pigments mainly includes the following three aspects:

Physical anti-corrosion

Physical anti-corrosion pigments can react with the film-forming agent in the paint to form a dense anti-corrosion coating and enhance the physical anti-corrosion effect. For example, lead-containing pigments react with paint to form lead soap, which makes the anti-corrosion coating more dense and reduces the penetration of harmful substances.

chemical corrosion protection

When acidic or alkaline substances penetrate the coating, anti-rust pigments can neutralize these harmful substances and turn them into harmless substances. Zinc oxide, aluminum hydroxide, barium hydroxide and other amphoteric compounds can neutralize acidic or alkaline harmful substances, or react with water and acid to generate alkaline substances, thereby protecting metal surfaces.

Electrochemical corrosion protection

The anti-rust pigments in the coating react with moisture and oxygen in the coating to form anti-corrosion ions. These ions can passivate the metal surface and prevent the dissolution of iron ions, thus playing an anti-corrosion role. For example, zinc-rich coatings mitigate metal corrosion by taking advantage of zinc's lower electrical potential than steel, making it a sacrificial anode.

Conclusion :

The development history of anti-corrosion coatings reflects the continuous promotion of scientific and technological progress and industrial needs. Different types of anti-corrosion coatings and anti-rust pigments not only extend the service life of various facilities and materials, but also improve their performance and safety in various fields. With the increasing awareness of environmental protection, future anti-corrosion coating trends will pay more attention to low pollution, high efficiency and sustainability. The emergence of emerging technologies such as non-toxic anti-rust pigments will further drive innovation in this area to ensure that our infrastructure and equipment can endure the test of time and environment.