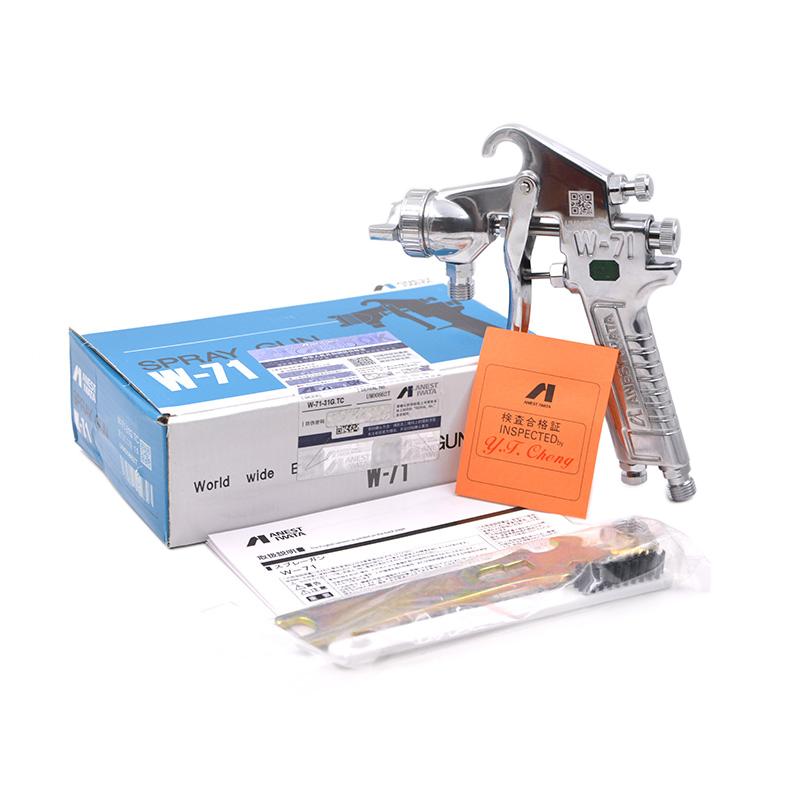

Airspraying defects and treatment methods

Air spraying defects and treatment methods

In air spraying technology, many different defects may occur. The causes of these defects and the corresponding treatment methods have many similarities with brushing. The following are some types of defects related to air spray technology, their causes and treatment methods:

Sagging: causes

Uneven spray pressure.

Spraying distance is too close.

Spraying speed and paint output are not balanced.

Too much spray applied.

The spray angle is incorrect.

The spraying environment temperature is too low.

The nozzle is too large, the pressure is too high, and the paint output is too large.

Approach:

Control spray pressure.

Keep the distance between 15 and 25cm.

Adjust spray speed to maintain balance with paint output.

Control the amount of spray applied.

Keep spraying vertically.

Increase ambient temperature.

Choose the appropriate nozzle and pressure to control the amount of paint.

Bubbles: causes

The sprayer's filtration system failed.

Sprayed too thickly at one time.

The pressure of the Spray Gun is too high and the spraying distance is too far.

The solvent evaporates too quickly.

Approach:

Check and repair filtration system.

Control the amount of spray applied.

Control spray pressure and distance.

Add an appropriate amount of solvent that evaporates slowly.

Whitening: Causes

Water is mixed into the paint.

The humidity in the spray room (cabinet) is too high.

The wind speed in the spraying room (cabinet) is too high.

Too much low boiling point solvent was added.

Approach:

Check the oil-water separator.

Control the relative humidity in the spray booth (cabinet).

Control the wind speed between 50 and 80cm/s.

Control the amount of low boiling point solvent added.

Orange peel: causes

The spraying pressure is insufficient and the paint atomization effect is poor.

Spraying distance is too far.

The viscosity of the paint is too high and the paint atomization effect is poor.

The paint temperature is too low and the leveling property is poor.

Gun moves too fast or too slow.

The nozzle is worn and the paint atomization effect is poor.

Select an inappropriate Spray Gun model.

Approach:

Increase spray pressure.

Control spraying distance.

Adjust paint viscosity.

Increase spraying temperature to improve leveling.

Correctly grasp the moving speed of the Spray Gun.

Replace nozzle.

Choose the right Spray Gun based on the paint properties.

Particles: causes

The Spray Gun moves too fast, causing uneven spraying.

The spraying pressure is too low and the paint atomization effect is poor.

The nozzle aperture is small, the pressure is too high, the spraying distance is too far, and the paint liquid solidifies before it reaches the surface.

The spraying amount is too small and a continuous coating film is not formed.

The sprayer's filtration system failed.

There are dust, abrasive dust, wood hair and other debris on the surface of the base material.

A used Spray Gun was not cleaned thoroughly, causing paint particles to spray out.

Approach:

Control the moving speed of the Spray Gun, which should be between 30 and 50cm/s.

Adjust spray pressure.

Spray correctly according to operating procedures.

Increase spray volume.

Check and repair filtration system.

Before spraying, thoroughly clean, remove dust and wood hair from the surface of the substrate, and purify the air.

Clean the spray equipment promptly and thoroughly after spraying.

In a word, the types, causes and treatment methods of defects in air spraying technology have many similarities with brushing. By understanding the causes of these defects and corresponding treatment methods, the coating quality can be effectively improved to ensure that the appearance and performance of the painted surface meet the expected requirements.