Advantages and Categories of Mayer Rods in Spreader wet-film prepative

In the paint, ink and other industries, the preparation of wet film coating is a vital process. In this field, the wire Bar Coater, as one of the key tools for preparing wet films for coating, has eye-catching advantages. Letâs explore the benefits and different categories of wire bar applicators.

Advantages Overview

One of the reasons why the wire Bar Coater is widely used is that it has many advantages: Economy, High precision and uniformity ,Easy to operate.

Compared with other coating tools, wire Bar Coaters are more affordable and help reduce overall production costs. When coating on a wire rod, the wet film can be prepared with high precision and the coating uniformity is good, ensuring the quality of the product. Easy to use and operate, the replacement and installation operations are simple and convenient, which improves work efficiency.

Category introduction

In the market, wire bar applicators are mainly divided into the following four categories: Wire-wound type, Split line type, Formed typeDouble winding and

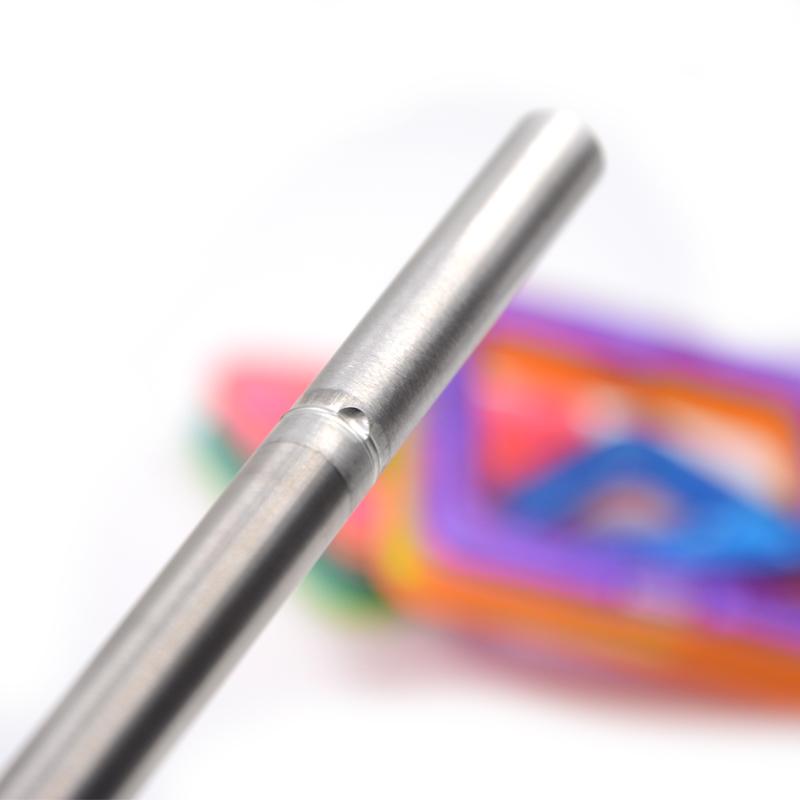

Wire-wound wire rod - The main structure of this type of wire rod is made of steel wire, and steel wires of different diameters form wire rods of different thicknesses. The manufacturing process of this type of wire rod is complex and the price is high, but the precision is also relatively high.

Spacer type wire rod - The structure and manufacturing method of the wire rod are similar to that of the wire wound wire rod. It is also made of steel wire, but the difference is that there are larger gaps between the steel wires of the wire rod. This type of wire rod has few market applications.

Double-wound mayer-rod - This type of wire rod has two steel wires wound into two layers, which has better coating characteristics than a single wire-wound wire.

Formed scraper rod â This type of wire rod is machine-pressed from metal material. Compared with wire-wound wire rods, the manufacturing process is simpler and the price is more affordable.

Wire Bar Coaters have attracted much attention due to their multiple advantages in the preparation of wet films for coating and their diversity in different categories. Whether it is cost-effectiveness or work efficiency, choosing the right wire Bar Coater is of great significance to industry production. For industry practitioners, choosing an appropriate wire Bar Coater based on actual needs and product requirements will help improve production efficiency and product quality.

- 1Application of Mayer Rods in protective coating prepative

- 2Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

- 3Application of Mayer Rods in composite coating prepative

- 4Several Common Experimental Spreader Methods and Their Applications

- 5Application of Mayer Rods in Water-based ink Moulding

- 6Technical method and application of preparing nanometer silver wire thin films with Mayer Rods

- 7The experimental case of OSP Mayer Rods at inks Moulding [with video]

- 8Why Do Film Applicators Need to Change Their Wires Regularly?

- 9Mayer-Rod (Mayer Rods) Preparative 2D Copper Nanosheets