The overlooked role of Mayer Rods in laboratory wet-film preparation

In the laboratory, wet film preparation is the basis for coating testing. However, many times, inspectors often overlook a crucial step, which is the selection of a suitable wire Bar Coater. The wire rod coater is a coating coating rod that uses the Mayer rod principle. It plays an indispensable role in the wet film preparation process and is crucial to the control of the uniformity and film thickness of the sample film layer. This article will explore the critical role of the wire Bar Coater in wet film preparation in the laboratory and highlight its importance in coating inspection.

The basis of coating inspection - wet film preparation

Before proceeding with coating inspection, the first priority is to prepare the wet film. Wet film refers to a thin, undried layer of paint or coating material. Its uniformity and film thickness directly affect the accuracy and repeatability of subsequent inspections. If the wet film is not prepared properly, it may result in uneven coating, uneven film thickness or peeling, which will affect the test results.

Understand the principles of wire bar applicators

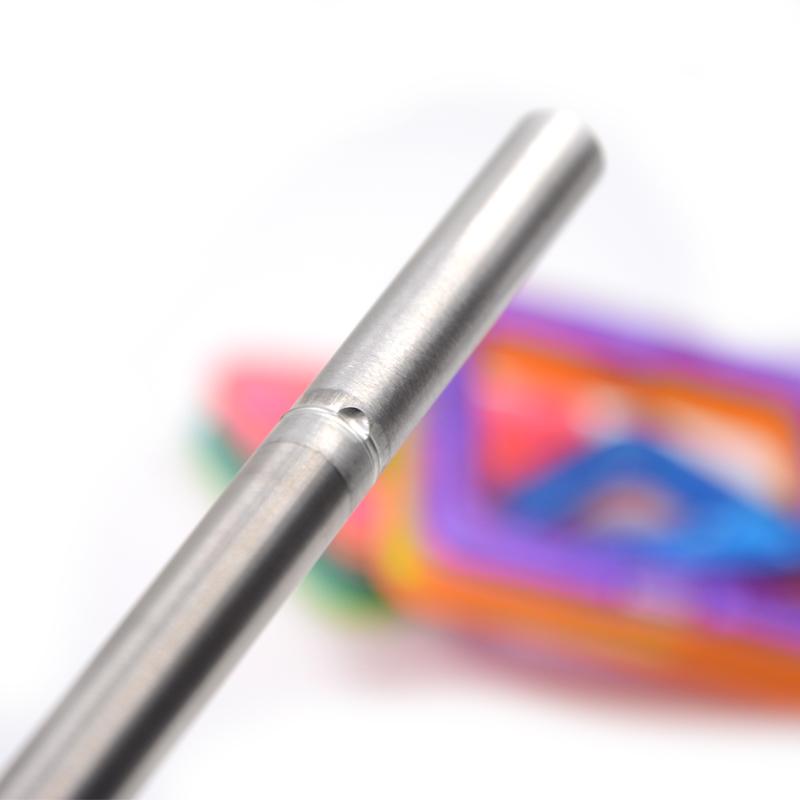

The mayer-rod is a coating tool based on the Mayer rod principle. Its working principle is to pour the paint or coating material into a container, and then use a coating rod (wire rod) to evenly coat the coating on the surface of the substrate. The surface of the coating rod usually has a uniformly distributed uneven texture, which helps achieve uniform distribution of the coating and control of the film thickness. Choosing the right wire bar applicator is critical to producing an even, consistent wet film.

Wire bar applicators ensure that paint or coating materials are evenly distributed on the substrate. This helps avoid spots, voids or uneven areas in the coating, ensuring consistency across test samples. Wire bar applicators allow the user to precisely control wet film thickness. By selecting the appropriate coating rod size and adjusting the coating speed, the required film thickness can be achieved to ensure test accuracy. Wire bar applicators provide a high degree of repeatability in preparing wet films. This means that wet films of the same thickness and uniformity can be prepared at different time points to allow for multiple tests and comparative analyses.

Choose the right wire bar applicator

To ensure the accuracy and reliability of coating inspection, it is crucial to select the appropriate wire Bar Coater. Here are some factors to consider when choosing a wire bar applicator:

Coating rod specifications need to consider different processes, widths and groove depths. Coating rods are suitable for different film thickness requirements. Choose the appropriate coating rod size based on your testing needs. Adjusting the coating speed when scraping the film can affect the film thickness and uniformity of the wet film. Adjust according to desired preparation parameters. Make sure the wire bar applicator is compatible with the paint or coating material being used, taking into account viscosity, fineness and corrosivity issues to avoid material reaction or corrosion. It is therefore important to choose a wire Bar Coater with the right fit to suit different testing requirements and coating materials.

Wet film preparation is a critical step in coating inspection, and the wire bar applicator is a key tool in achieving an even, consistent wet film. Proper selection and use of wire bar applicators helps ensure accuracy and repeatability of coating inspections, thereby increasing the confidence in test results. Therefore, do not ignore the importance of the wire Bar Coater in coating testing. It is the basis for ensuring uniform film layer and correct film thickness of the prepared sample.

- 1Application of Mayer Rods in protective coating prepative

- 2Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

- 3Application of Mayer Rods in composite coating prepative

- 4Several Common Experimental Spreader Methods and Their Applications

- 5Application of Mayer Rods in Water-based ink Moulding

- 6Technical method and application of preparing nanometer silver wire thin films with Mayer Rods

- 7The experimental case of OSP Mayer Rods at inks Moulding [with video]

- 8Why Do Film Applicators Need to Change Their Wires Regularly?

- 9Mayer-Rod (Mayer Rods) Preparative 2D Copper Nanosheets