Fineness gauge selection guide notes

What is fineness?

Fineness is an important indicator for checking the particle size or uniformity of dispersion of pigments (fillers) in paint or paint slurry, usually expressed in microns (μm). The fineness of the coating directly affects the gloss, appearance, corrosion resistance and storage stability of the coating. Generally speaking, the smaller the pigment particles and the higher the dispersion, the finer the fineness, the smoother the paint film, and the better the decorative effect.

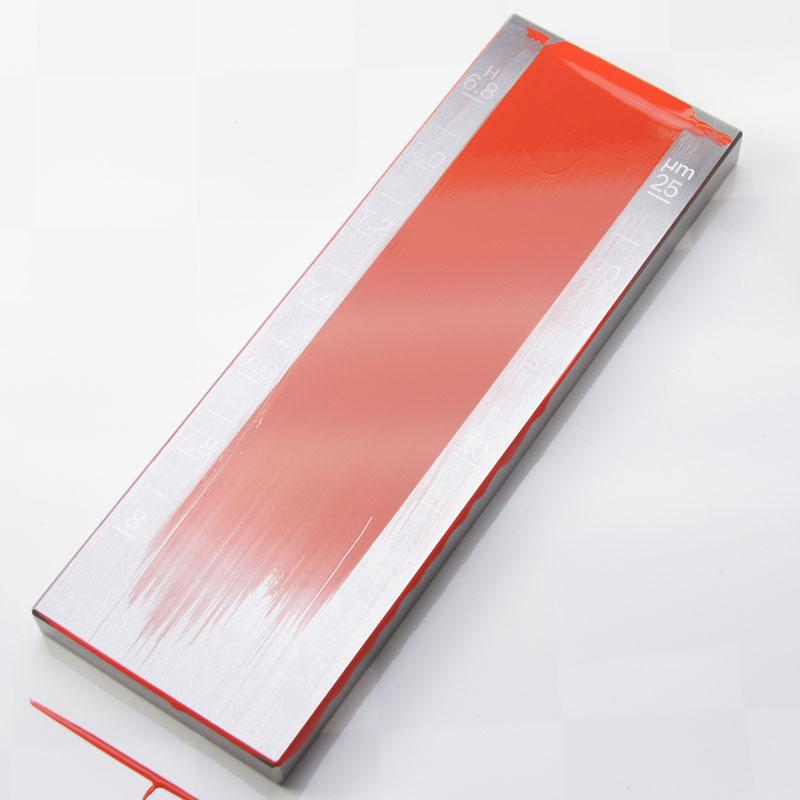

Fineness plate principle

Fineness is usually measured using a scraper Fineness Meter. It consists of a polished flat plate and a scraper. The flat plate has one or two grooves of gradual depth parallel to the long sides. This design allows the groove depth to gradually decrease from one end to zero, allowing different specifications of pigments to be measured.

Fineness board classification

Groove style distinction: single groove (standard, small single groove, large single groove) and double groove (standard, small double groove, large double groove)

Measuring range distinction: ranging from 015μm to 500μm

Resolution distinction: usually 1μm~5μm, specific graduation values ââcorrespond to different ranges

Unit distinction: micron (um), Hagerman (H), mil (MILS), North (PCU)

How to choose fineness board

For the estimated fineness value, for 30 μm and below, select a 50 μm range scraper Fineness Meter; for 31 to 70 μm, select a 100 μm range scraper Fineness Meter; for 70 μm and above, select a 150 μm range scraper Fineness Meter. When you have no specific concept, ask about the sample type:, understand the sample fineness range, and select the corresponding range. Or understand the standard requirements and select according to the fineness range specified by the relevant standards.

Single slot and double slot

The double-slot fineness plate can perform two tests at the same time, which improves reproducibility and reproducibility, and is especially suitable for situations where high accuracy is required.

Reason for price difference

Costs vary, primarily due to differences in manufacturing precision and materials. Cheaper products may sacrifice accuracy and durability, while high-quality fine-gauge boards require precise manufacturing and calibration processes.

*If special materials have corrosive requirements, corrosion-resistant materials such as ceramics can be used. Not all suppliers can provide all types of fineness plates. Especially when special materials and high-precision requirements are required, you need to carefully select the appropriate supplier. Through the above guidance, I hope you can more clearly choose the fineness board that suits your needs. Remember, the right tools make your job more efficient and ensure the final results of your paints and pigments.

- 1Introduction to the function, production process and use method of latex paint Fineness gauge

- 2Basic Principle and Application Analysis of Coating Fineness Scraper

- 3Frequently Asked Questions about Fineness Plates in 2022

- 4The maximum particle size of the filler is 25μm. What range of fineness plate is better?

- 5What properties do ceramic decorative water-based coatings need to test? What requirements are met?

- 6Comparison of four scraper Fineness Meters of different brands with the same range

- 7How to measure the fineness of lithium-ion battery slurry [Practical knowledge dry goods]

- 8Appreciation of beautiful pictures of real shots of single-slot fineness boards in modern environment

- 9Selection scheme of common performance testing instruments for architectural paints