Application of Automatic Film Applicator for Epoxy resin on tinplate

The application of automatic coating machine to scrape-coat epoxy resin on tinplate (also called tinplate iron) is a coating technology that is usually used to improve the anti-corrosion and corrosion resistance of metal surfaces, increase the aesthetic appearance, and protect the metal. Protection from erosion in the environment.

Preparation:

1) Surface treatment: The surface of tinplate needs to be pre-treated to ensure that the surface is clean, flat, free of oil stains, rust, etc. Usually, surface treatment includes pickling, phosphating and other steps.

2) Epoxy resin: Choose an appropriate epoxy resin coating material. Usually this coating has excellent anti-corrosion, corrosion resistance and weather resistance.

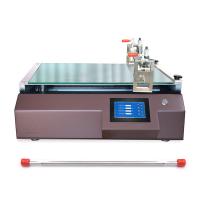

Automatic film coating machine:

Principle of film coating machine: Automatic film coating machines usually use scraper coating technology. This technique involves a coating blade or scraper that works through a mechanical system to create an even coating on the tinplate surface.

Coating thickness control: Automatic coating machines usually have a coating thickness control system to ensure that the thickness of the coated epoxy resin film meets the design requirements.

Operating procedures:

The tinplate is placed on the automatic coating machine, fixed with tape or clamps, and the coating speed and stroke are set. Then use the wire rod or scraper on the coating machine to evenly coat the epoxy resin on the tinplate surface to form a thin film. Coated tinplate usually needs to go through a curing process to solidify and harden the epoxy coating to form a strong protective layer. If you need to speed up curing, you can use a small oven for drying and curing.

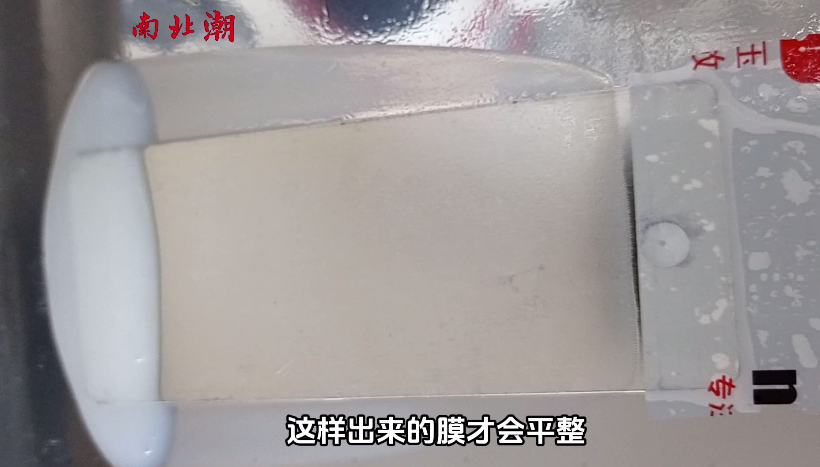

Below is the scraping and coating of epoxy resin on the tinplate made by NBCHAO Technology for users. The effect is still very good.

In this experiment, the viscosity of the epoxy resin is relatively low and the fluidity is relatively high, so the scraping speed is set relatively fast, so that the scraped film is relatively smooth and uniform.

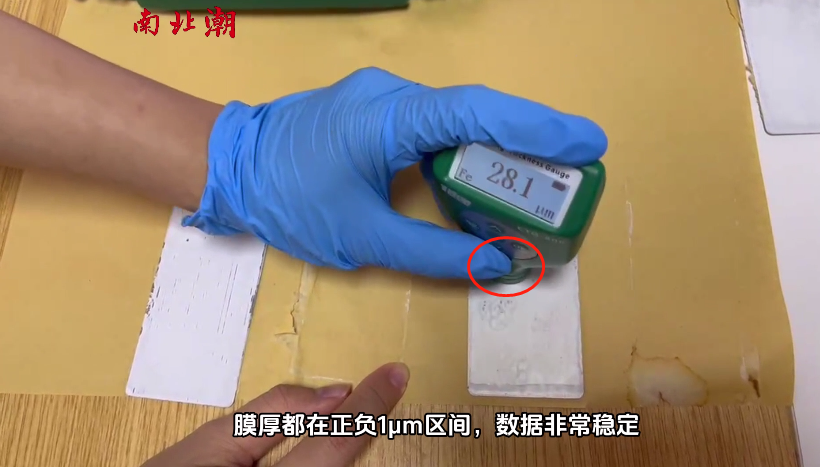

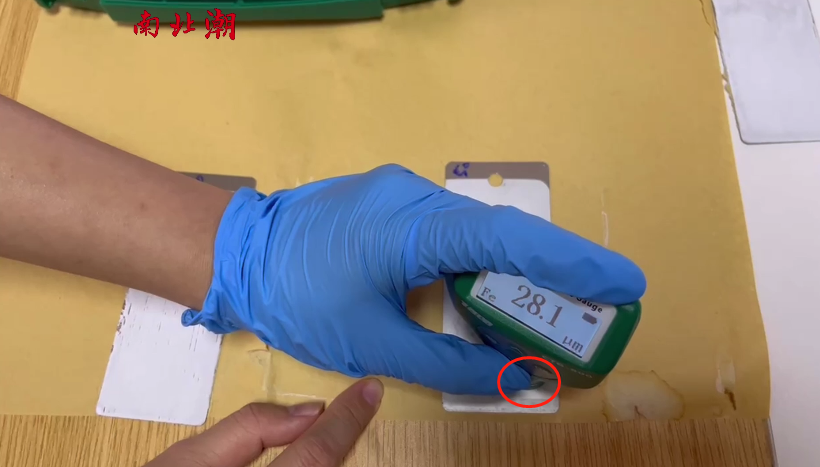

Thickness verification

After the coating on the tinplate was cured, the technology tested and verified the thickness uniformity. Through multi-point testing, the thickness was relatively consistent and uniform.

Application areas:

Food packaging: Tinplate coated with epoxy resin can be used inside food cans to prevent direct contact between metal and food and prevent corrosion.

Industrial Uses: In some industrial applications, such as equipment housings, pipes, etc., coatings can provide additional protection against corrosion and wear.

Precautions:

Surface pretreatment: Surface pretreatment is crucial, as it directly affects the adhesion and effect of the coating film.

Coating blade selection: Select the appropriate type and hardness of coating blade to ensure even coating.

Environmental control: Ensure that the coating process is carried out under appropriate environmental conditions, including temperature, humidity, etc.

Automated applicator technology for applying epoxy resin provides an efficient solution for metal protection, decoration and functionality.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application of laboratory coater in LED fluorescent film Spreader

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Application and selection of laboratory coater in PDMS thin film prepative

- 7Scraping machine selection case: film substrate large size high accuracy scraping solution

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research