Laboratory Film Applicator Drive Selection: Servo Motor and Stepper Motor

When it comes to the choice of motor for laboratory coating machines, people generally hesitate between servo motors and stepper motors. Customers often have doubts: Which motor is more suitable for experimental coating needs? Is it necessary to spend more money to choose a servo motor model? Let's first understand the principles of the two motors.

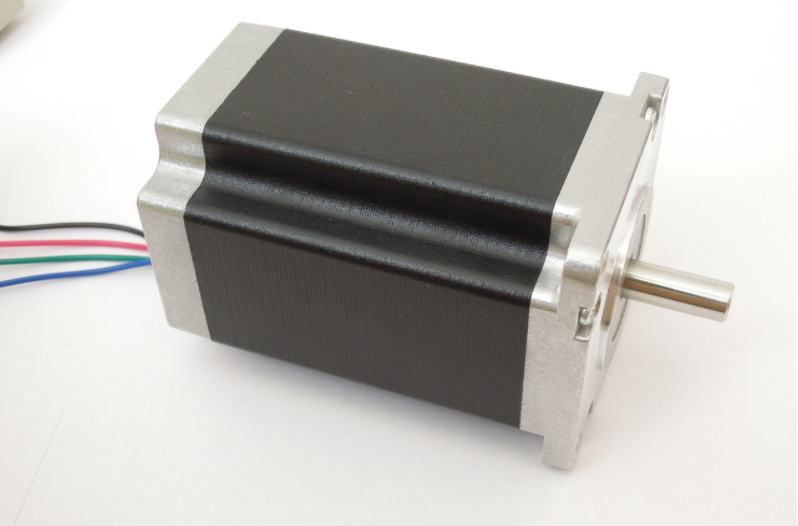

What is a stepper motor?

A stepper motor is a type of electric motor characterized by its ability to convert electrical signals into discrete step motion. It rotates step by step according to the step angle, and the angle of each step is fixed. Stepper motors usually consist of a stator containing multiple electromagnetic coils and a rotor that carries magnetic poles. When current passes through the coil, the resulting magnetic field interacts with the magnetic poles on the rotor, pushing the rotor to the next step angle. Stepper motors are an open-loop control system that are typically used in applications that require simple and crude control, relatively low precision, and low-speed motion, such as printers, CNC machine tools, robots, etc. Because of their relatively simple structure, low cost, and no need for feedback systems, stepper motors show good cost performance in some applications.

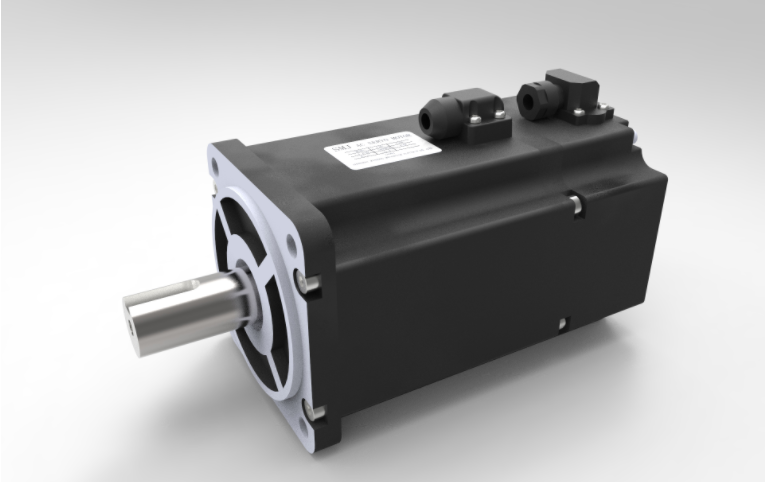

What is a servo motor?

A servo motor is a motor that can achieve high-precision position control, usually through a feedback system to achieve closed-loop control. It has the ability to accurately monitor speed and position, as well as the ability to adjust motion parameters on the fly, allowing it to more precisely control the motion of mechanical systems. Servo motors typically include a motor, an encoder or other position sensor, and a controller. By comparing the actual position to the desired position in real time and making adjustments through feedback mechanisms, servo motors are able to function in high-precision and high-performance applications such as CNC machine tools, printing presses, robots, automation systems, etc. Its closed-loop control system enables the servo motor to cope with changing loads and working conditions, providing more reliable and stable motion control, and is suitable for industrial and laboratory applications that require high motion accuracy.

From the perspective of the principles of the two motor technologies, servo motors have more obvious advantages than stepper motors, and their costs are also higher.

So for laboratory coating machines, is it necessary to choose a servo motor at high cost? In fact, in some specific application scenarios of laboratory coating machines, the use of servo motors may indeed have advantages over stepper motors. Here are some examples:

1) High-precision requirements: If the laboratory coating machine requires high-precision coating, such as film coating at the nanometer or ultra-thin micron level, the closed-loop control system of the servo motor can provide higher position and speed accuracy to ensure Film uniformity and quality.

2) Variable speed and variable load: The film coating machine may face different speed and load requirements during operation. Servo motors are more flexible in their ability to adjust motion parameters in real time to adapt to changing process conditions, while stepper motors may be less adaptable in this regard.

3) High-speed coating: If the laboratory coating machine requires higher coating speeds, servo motors can usually provide better high-speed performance while maintaining stability. Stepper motors may experience resonance or out-of-step problems when moving at high speeds.

4) Real-time adjustment and feedback: Servo motors are equipped with feedback devices, such as encoders, that can provide real-time position information. This allows the system to promptly correct any position errors and achieve more precise motion control. Stepper motors are usually controlled in an open loop and lack real-time feedback, which may affect the stability and accuracy of the system.

5) Adaptive control: Servo systems usually have adaptive control algorithms that can automatically adjust control parameters according to changes in working conditions to adapt to different coating conditions and material properties. This makes the servo motor system more suitable for complex laboratory research and diverse coating requirements.

In general, if the application scenario of the laboratory film coating machine has high requirements for accuracy, speed and stability, and the budget allows, then it may be more advantageous to choose a servo motor. However, in some simple coating applications, stepper motors may still be an affordable option. Specific choices will also need to be made based on the specific needs and budget of the laboratory.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Laboratory Automatic Film Applicator in Coating Battery Slurry on Copper Foil and Aluminum Foil

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research