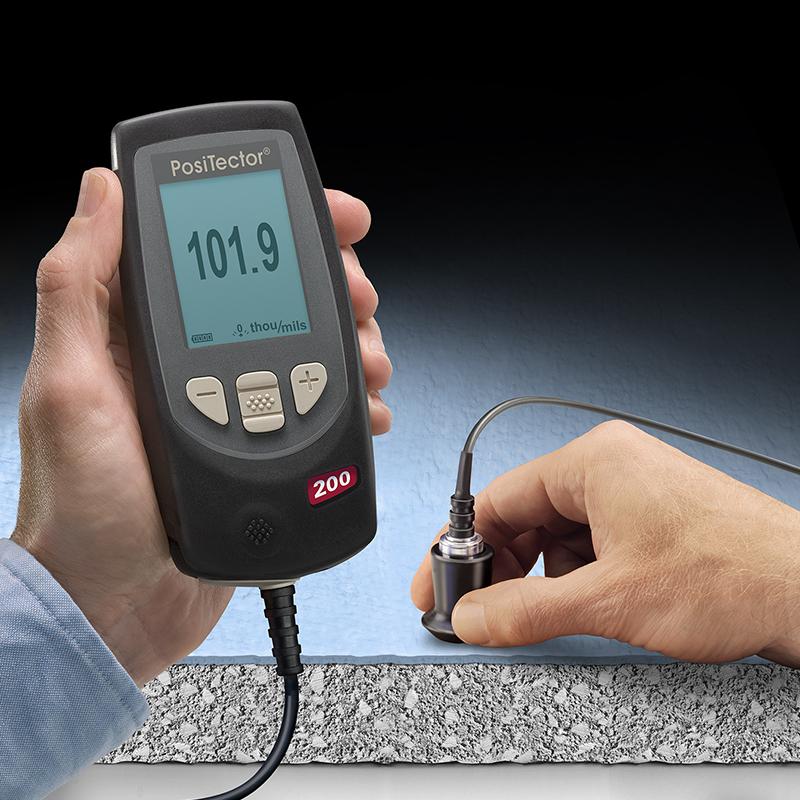

Measurement principle of commonly used coating Thickness Gauge

Coating Thickness Gauge is a key instrument widely used in industry for measuring the thickness of coatings on metal substrates. This technology is critical to ensuring the quality, performance and consistency of coatings. This article will conduct an in-depth study of the measurement principles of several commonly used coating Thickness Gauges, including ultrasonic pulse echo method, reflection eddy current method, and variable reluctance method.

1. Ultrasonic pulse echo method

1.1 Basic principles

The ultrasonic pulse echo method uses the propagation characteristics of ultrasonic waves to measure coating thickness. When ultrasonic waves are incident on the coating, part of the ultrasonic waves will be reflected back, while the remaining ultrasonic waves will enter the interior of the coating and be reflected again. By measuring the time difference between reflected echoes, the thickness of the coating can be calculated.

1.2 Scope and limitations of application

Scope of application: Suitable for materials that can allow ultrasonic waves to propagate inside the material at a certain speed and be reflected from the back.

Limitations: Metal materials with coarse grain structures may cause strong scattering and reduced penetration depth. For samples with rough surfaces, scattering effects can cause irregular changes in readings.

2. Reflection eddy current method

2.1 Basic principles

The reflective eddy current method uses the high-frequency electromagnetic field generated by the probe to generate eddy currents in metal conductors. The amplitude and phase of the eddy currents are related to the thickness of the non-conductive covering. By measuring changes in probe parameters, the thickness of the coating can be inferred.

2.2 Scope and limitations of application

Scope of application: Mainly used to measure non-magnetic coatings on metal substrates.

Limitations: For coatings with different electromagnetic parameters, a complex calibration process is required. The measuring range is small and it is difficult to apply to coatings with a thickness exceeding 1mm.

3. Variable reluctance method

3.1 Basic principles

The variable magnetoresistance method is used to measure non-magnetic coatings on metal substrates. When the coating is small, the magnetic field in the air gap can be considered uniform and the thickness of the coating can be inferred by measuring the change in reluctance.

3.2 Scope and limitations of application

Scope of application: Mainly used to measure non-magnetic coatings on magnetic metal substrates.

Limitations: The requirements for the sample are high and a complex calibration process is required. When the coating thickness is greater than 25 μm, the error is approximately proportional to the coating thickness.

Various coating Thickness Gauges have their own unique measurement principles and application ranges. When choosing an appropriate measurement method, the nature and requirements of the coating being measured need to be considered. The ultrasonic pulse echo method is suitable for a certain range of materials, the reflective eddy current method is mainly used for non-magnetic coatings, and the variable reluctance method is suitable for non-magnetic coatings on magnetic metal substrates. For different application scenarios, choosing an appropriate coating Thickness Gauge is the key to ensuring measurement accuracy and reliability.

-

-

-

-

-

QNix 9500 Coating Thickness Gauge, basic$ 1194.00

-

-

-

-

- 1Nondestructive measurement Coating thickness

- 2Principle, application and selection of traffic coatings Coating Thickness Gauge

- 3Principle, Application and Selection of Eddy current Coating Thickness Gauge

- 4Principle, Application and Type Selection of Electronic Coating Thickness Gauge

- 5Explore the principle, application and selection of phosphating layer Coating Thickness Gauge

- 6Principle, Application and Type Selection Analysis of Chrome Coating Thickness Gauge

- 7Principle, Application and Selection of Coating Thickness Gauge for inner wall of small pipe

- 8Basic principle and application scenario of steel Coating Thickness Gauge

- 9Principle and Application Analysis of Coating Thickness Gauge