Principle and application analysis of microporous gloss meter

introduction

In various industrial production and scientific research, the measurement of surface gloss has a crucial impact on the quality of product appearance and the effect of surface treatment. As a high-precision measuring instrument, the micropore Glossmeter has the ability to measure minute surface features in detail and is widely used in surface gloss analysis of coatings, plastics, paper, metals and other materials. This article will conduct an in-depth study of the principle, structure, application scenarios and future development trends of the micropore Glossmeter, providing readers with a comprehensive understanding of this precision instrument.

The principle of micropore gloss meter

The working principle of the micropore Glossmeter is based on the reflection and scattering characteristics of light. By analyzing the reflected light on the sample surface, the precise value of surface gloss can be obtained. Micropore gloss meters use a light source of a specific wavelength and intensity, usually white light or a single wavelength of light. This light source is illuminated onto the surface of the sample to be measured. Light on the surface of the sample will be reflected and scattered, and the micropore Glossmeter analyzes the surface gloss of the sample by detecting the intensity and distribution of these reflected lights. Micropore gloss meters typically use very small apertures, making the measurement very focused. This ensures high-precision measurement of tiny surface features. The reflected light is detected by a photodiode or other photosensitive element and converted into an electrical signal. The built-in processor of the micropore Glossmeter analyzes the detected data, calculates the surface gloss value, and expresses it in specific units.

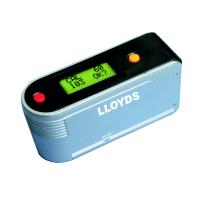

A micropore gloss meter usually looks like a delicate instrument, containing components such as a light source, micropores, Detectors, data processors and display screens. The light source system provides a light source that irradiates the sample surface, and its wavelength and intensity have an important impact on the measurement results. Micropores are the core component of micropore Glossmeters, which achieve high-precision measurement of surface microstructure through tiny apertures. The Detector is responsible for receiving the reflected light and converting it into an electrical signal for subsequent data processing. The data processor processes and analyzes the detected light signal, calculates the surface gloss value, and performs unit conversion. The display screen is usually used to display measurement results in real time, allowing users to intuitively understand the surface glossiness of the sample.

Application of micropore gloss meter

Micropore gloss meters can be used to measure the gloss of coating surfaces to ensure the quality and appearance of coatings and paints. In the production of plastic products, micropore Glossmeter can be used to detect the surface gloss of injection molded products to ensure their appearance quality. Used to measure the glossiness of the paper surface and the printing quality of the printed matter. Micropore gloss meters are widely used in the metal surface treatment industry to measure the gloss of coatings and coatings on metal surfaces. In the manufacturing of ceramic and glass products, micropore Glossmeters can be used to measure surface gloss to ensure product quality.

Future micropore gloss meters may introduce multi-wavelength measurement technology to more comprehensively and accurately describe the optical properties of the sample surface. Micropore gloss meters may integrate intelligent technology to realize automated measurement, data analysis and result display, improving ease of use. With the advancement of technology, micropore gloss meters will be used in more materials and industries, expanding their scope of application. Future micropore gloss meters may be smaller and lighter, easier to carry and operate, and suitable for more scenarios. With the continuous improvement of technology, micropore Glossmeters will achieve higher measurement accuracy and smaller resolution to meet the measurement needs of fine surfaces.

Conclusion

As a precision instrument, the micropore Glossmeter provides an important tool for production and research in various industries through its high-precision measurement capabilities. In modern industry, the requirements for product appearance quality are getting higher and higher. With its unique measurement principle and structural design, micropore Glossmeter plays an important role in the field of surface gloss measurement. In the future, with the continuous development of technology, micropore gloss meters will continue to innovate and provide more accurate and convenient surface gloss measurement solutions for all walks of life.

- 1Gloss inspection method of slurry inks

- 2Principle and Application of Glossiness Tester

- 3Working Principle and Application of Metal Gloss Meter

- 4Basic principle and application analysis of insulating paint gloss Detector

- 5Working principle and application analysis of film Glossmeter

- 6 FZ/T 01097 Analysis of fabric gloss test method

- 7Evaluation and Application of Optical Properties of Powder coatings

- 8Coating coatings - Determination of surface gloss and Gloss meter

- 9The Importance and Method of Gloss Measurement of Paint Film