Introduction of calibrating method of metal coating Thickness Gauge

The thickness of the metal coating is generally measured by the coating Thickness Gauge or the coating Thickness Gauge, but the coating Thickness Gauge does not have a calibration specification at present, and the verification of the coating Thickness Gauge, JJG 818-2005 "Magnetic and eddy current cladding Thickness Gauge verification regulations" is to use the non-metallic thickness sheet as the standard part, so it is inconsistent with the medium of the measured piece, and the reliability of the measurement results can not be determined. and to assess the uncertainty and the method used to calibrate the coating Thickness Gauge.

The coating Thickness Gauge is a special instrument for measuring the thickness of metal plating, but there is no verification procedure for the coating Thickness Gauge in CHINACalibration Specifications. Through the test, the metal coating thickness standard sample was made to calibrate all kinds of metal coating Thickness Gauges.

1. Preparation of standard samples

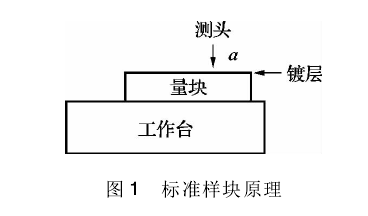

Take a thickness of about 10 mm 5 equal gauge block, on the upper working surface 1/2 of the area to be calibrated metal layer to be calibrated, such as chromium or copper, zinc, nickel, gold, etc., and then measure the thickness of the coating on the optical meter, and then use the gauge block with the known thickness of the coating to calibrate the Thickness Gauge. As shown in Figure 1, the gauge block with half of the coating on the upper working surface is placed on the optical meter workbench, the optical measuring probe and the gauge block are adjusted, the part without plating is zeroed, and then the measuring block is moved, and then the probe is aimed at any point A with the coating, and the reading on the optical gauge is directly read, that is, the thickness of the plating.

In order to guarantee accuracy, it can be measured multiple times at point A, and its average value can be taken as the coating thickness. In the same way, the metal layer to be calibrated can be plated on a 4 or even 3 equal gauge block, and the thickness of the coating can be measured with a vertical contact interferometer or a high-precision bit meter sensor, if only a different uncertainty component is introduced into the error analysis or uncertainty evaluation of the measurement results.

The standard sample block is selected to make the standard sample block, mainly considering the stability of the measuring block and the flatness and parallelism of the working surface, which has a relatively high requirements, and has little impact on the uniformity of the coating. Although this method is simple and the whole process is not complicated, it is necessary to pay special attention to the following issues:

(1) In the process of electroplating the measuring block, it is necessary to ensure that the flatness and parallelism of the measuring block do not change;

(2) In addition to the plating layer on half of the working surface on the gauge block, any other part shall not be stained with the plating (according to the current electroplating process and test, this requirement is completely achievable);

(3) When calibrating the coating Thickness Gauge, the calibration point should coincide with the point A as much as possible.

2 Uncertainty is assessed

2. 2 Uncertain source

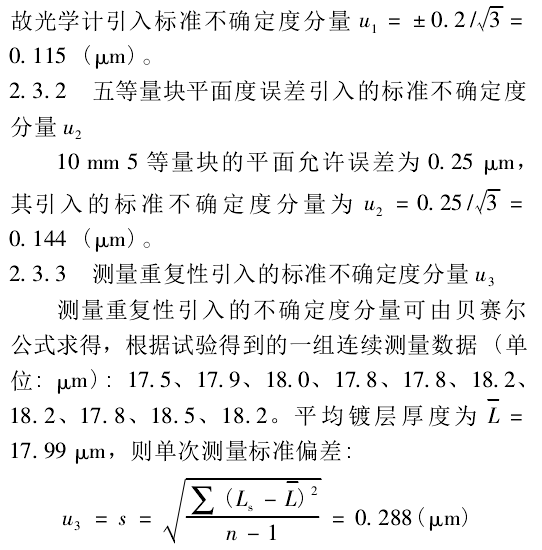

(1) The standard uncertainty component u1 introduced by the error of the vertical optical meter.

(2) The standard uncertainty component u2 introduced by the flatness error of the fifth magnitude block.

(3) Measure the standard uncertainty component u3 introduced by repeatability.

2. 3 Uncertainty assessment

2. 3. 1 The standard uncertainty component introduced by the error of vertical optical measurement u1 According to JJG 45—1999 "Verification Regulations for Optical Meters", it is ± 0 within the ± 60 μm index. 2 μm, ± 0 in ± 90 μm index. 25 μm[1], because the thickness of the coating is not more than 60 μm,

3 Concluding remarks

Once the uncertainty is assessed, the entire standard block manufacturing process is complete, which can then be used to calibrate the metal coating Thickness Gauge. Since the standard is a thickness determined on a laboratory optical gauge and can be calibrated at any time, it is very easy to use.

-

-

-

DONGRU DR120 Coating Thickness Gauge$ 168.00

-

DONGRU DR130 Coating Thickness Gauge$ 184.00

-

-

- 1Aluminum Panel platings thickness measurement

- 2Coating thickness Tester selection one or two points

- 3What is the significance of coating Thickness Gauge calibration? How to calibrate? When to calibrate?

- 4Film thickness arbitration method - metallographic method

- 5How to calculate Film thickness?

- 6Electroplated coating mass detection and evaluation method

- 7Determination of Bonding Strength of Hard Coating by Automatic Scratch meter

张平余;刘洪;王秀娥;顾则鸣;侯企贤;肖永东 - 《摩擦学学报》

- 8Film thickness measurement method of magnetic coating

- 9Film thickness test method overview