Small roll-to-roll coaters: an in-depth analysis and maintenance guide for common failures and solutions

Summary

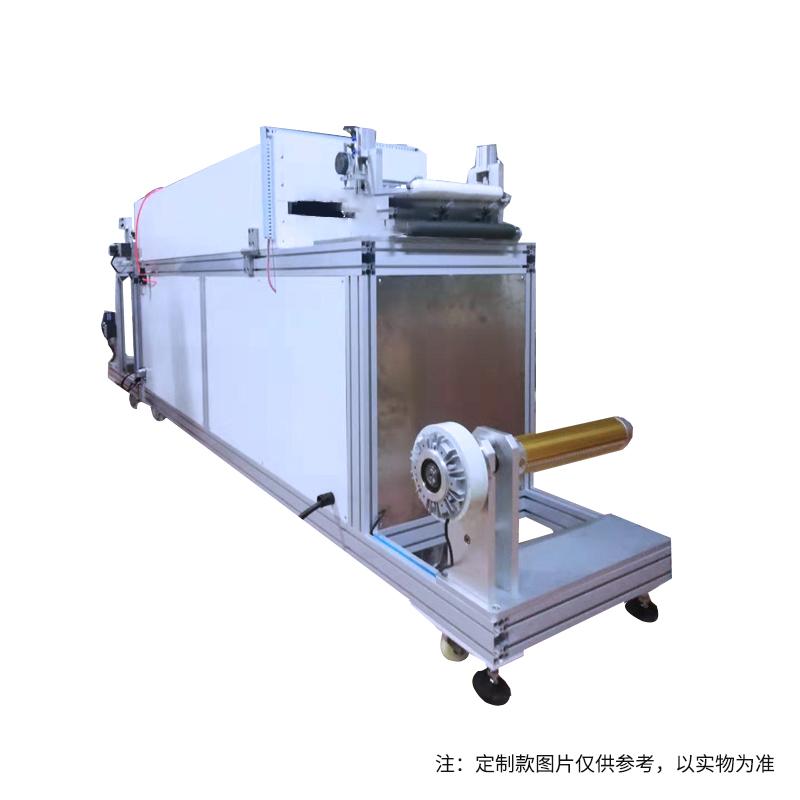

The small roll-to-roll coater is a piece of equipment widely used in printing, packaging, building materials and other industries. Its function is to evenly coat the coating on the roll. However, during use, some failures are often encountered, which not only affects the coating effect, but may also cause equipment damage. Therefore, timely detection and resolution of failures in small roll-to-roll coating machines is crucial to improving production efficiency and equipment stability. This article will delve into common failures and solutions for small roll-to-roll coaters to help users better use and maintain this equipment.

I. Introduction

1.1 Background

A small roll-to-roll coater is a device that evenly coats the coating on the surface of the roll through a roller. It is mainly used in printing, packaging, building materials and other industries. Because of its simple structure, convenient operation and low cost, it has been widely used in many fields.

1.2 Purpose

This article aims to conduct an in-depth study of the technical characteristics of small roll-to-roll coating machines, analyze their common faults, and provide corresponding solutions to help users better understand and operate this equipment.

2. Working principle of small roll-to-roll coating machine

Small roll-to-roll coating machines usually consist of a feeding device, a coating device, a drying device and a winding device. Through the synergistic effect of these components, uniform coating of the web is achieved. When the coil is fed into the coating device through the feeding device, the coating roller will evenly coat the coating on the surface of the coil, and then the coating will be quickly solidified through the drying device. Finally, the coated coil will be rolled out by the winding device. Take-up.

3. Common faults and solutions

3.1 Uneven coating

When coating is uneven, it may be due to the following reasons:

The surface of the coating roller is uneven

Paint viscosity is unstable

Improper distance between coating roller and web

solution:

Regularly inspect and maintain the coating roller to ensure its surface is smooth.

Adjust the distance between the coating roller and the web.

Check the viscosity of your paint regularly and adjust as needed.

3.2 Poor drying effect

Poor drying results may be caused by the following reasons:

Insufficient drying temperature

Not enough drying time

Drying device failure

solution:

Adjust the drying temperature and time to ensure the paint is fully cured.

Clean the drying unit regularly to ensure it is working properly.

3.3 Equipment noise is too loud

Excessive device noise may be caused by:

Equipment parts are loose

Unbalanced coating roller

Transmission system failure

solution:

Check equipment parts regularly and tighten loose parts.

Balance the coating roller to ensure proper operation.

Check the transmission system and repair the fault.

4. Maintenance

4.1 Regular inspection

In order to ensure the normal operation of the small roll-to-roll coating machine, users should regularly check whether all parts of the equipment are in good condition, including coating rollers, drying devices, transmission systems, etc.

4.2 Lubrication and maintenance

Regularly add an appropriate amount of lubricating oil to each lubricating part of the equipment to keep the equipment running smoothly and reduce wear and tear.

4.3 Cleaning and maintenance

Clean the surface and interior of the equipment regularly to prevent dust and foreign matter from accumulating and affecting the normal operation of the equipment.

5. Conclusion

Through the research of this article, we have an in-depth understanding of the working principle of small roll-to-roll coating machines, common faults and solutions, and the importance of maintenance. Proper use and maintenance of small roll-to-roll coating machines can not only improve production efficiency, but also extend the service life of the equipment and contribute to the development of related industries. Hopefully this article has provided useful information for users to better understand and operate small roll-to-roll coaters.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative