Automatic Film Applicator Technology Introduction and Application

introduction

With the continuous development of science and technology, various industries are looking for more efficient and precise production methods, and fully automatic coating machines, as an advanced coating technology, have gradually received widespread attention. The application fields of fully automatic coating machines involve many industries, including automobile manufacturing, electronic equipment, building materials, etc. Its advanced coating technology brings greater competitiveness to manufacturing companies. This article will deeply explore the technical principles, application fields, advantages and development trends of fully automatic coating machines, hoping to provide readers with a more comprehensive understanding.

1. Technical principles of fully automatic coating machine

1.1 Overview of coating machine

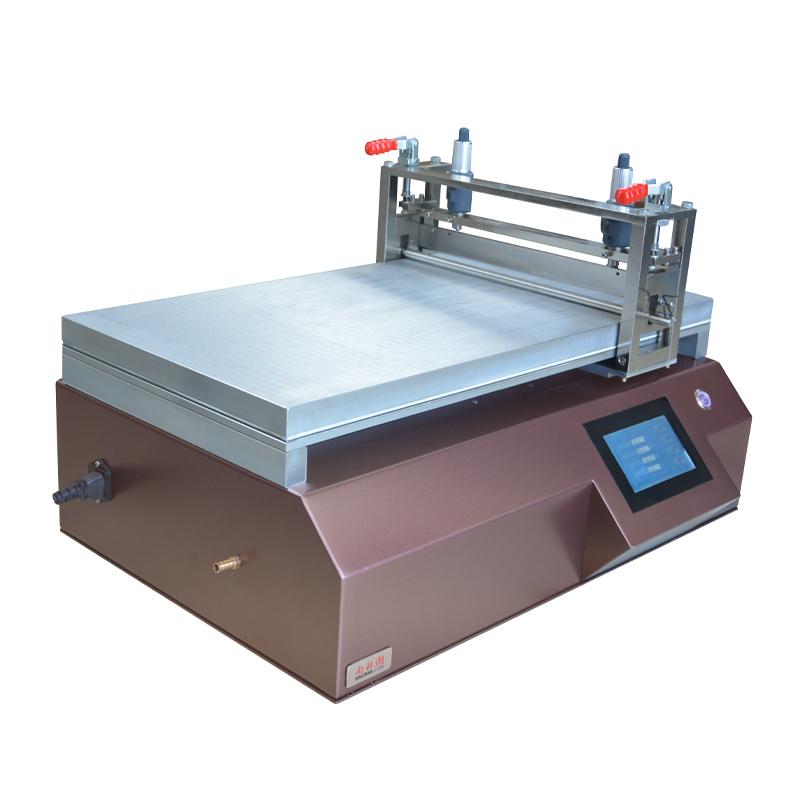

The fully automatic coating machine is an automated equipment based on advanced control technology, mainly used for coating and coating on the surfaces of different materials. The core parts of the coating machine include the conveying system, coating system, drying system and control system. During the operation, the materials are transported to the coating system through the conveying system, and then the coating process is accurately controlled through the control system, and finally the coating process is completed through the drying system.

1.2 Coating system

The coating system is a key component of the fully automatic coating machine, which mainly includes a spray head, a scraper coater and a roller coater. Different coating systems are suitable for different materials and coating needs. For example, a spray head is suitable for spraying liquid paint, while a roller coater is suitable for more uniform coating. Squeegees can be used to control the thickness and uniformity of paint.

1.3 Control system

The control system of the fully automatic coating machine uses advanced PLC (programmable logic controller) technology to monitor and adjust the coating process in real time through precise sensors and actuators. This enables the coating machine to achieve a high degree of automation and precise control, improving production efficiency and coating quality.

1.4 Drying system

After the coating is completed, the coating needs to go through a drying process to ensure the adhesion and durability of the coating. Fully automatic coating machines are usually equipped with hot air circulation systems or ultraviolet drying systems. The appropriate drying method is selected according to the characteristics of different coatings to ensure that the coating is dried in the shortest time.

2. Application areas of fully automatic coating machines

2.1 Automobile manufacturing

In the field of automobile manufacturing, fully automatic coating machines are widely used in body painting. The traditional manual coating method has problems such as a lot of paint waste and unstable coating quality. The fully automatic coating machine can achieve precise coating on the car surface through advanced coating systems and control systems, greatly improving the coating efficiency. quality, reducing paint waste while improving production efficiency.

2.2 Electronic equipment

In the field of electronic equipment manufacturing, many electronic products require special coatings on their surfaces to improve their waterproof, dustproof and other properties. The fully automatic coating machine can select an appropriate coating system according to different coating requirements to achieve efficient coating on the surface of electronic products and improve the durability and stability of the product.

2.3 Building materials

In the field of building materials, fully automatic coating machines are widely used to coat various building materials, such as steel structures, aluminum materials, etc. The automated coating process not only improves the consistency and quality of coating, but also reduces labor costs and paint waste in the manual coating process.

2.4 Other areas

In addition to the above application fields, fully automatic coating machines also play an important role in aerospace, home decoration, plastic products and other fields. With the continuous advancement of technology, the application fields of coating machines will continue to expand, bringing more development opportunities to various industries.

3. Advantages of fully automatic coating machine

3.1 Improve production efficiency

The fully automatic coating machine achieves a high degree of automation in the coating process through advanced coating systems and control systems. Compared with the traditional manual coating method, the fully automatic coating machine can complete the coating process more quickly and accurately, greatly improving production efficiency.

3.2 Reduce paint waste

Since the fully automatic coating machine can accurately control the coating thickness and uniformity, it avoids the waste of coating in manual coating. This not only reduces coating costs, but is also beneficial to environmental protection and sustainable development.

3.3 Improve coating quality

Through the advanced control system, the fully automatic coating machine can monitor various parameters in the coating process in real time and make timely adjustments to ensure the stability and consistency of coating quality. This helps improve coating accuracy and ensures coating adhesion and durability.

3.4 Reduce labor costs

Compared with traditional manual coating methods, fully automatic coating machines reduce reliance on labor and reduce labor costs. Companies can improve production efficiency and reduce coating personnel training and management costs by introducing fully automatic coating machines.

4. Development Trend of Fully Automatic Coating Machines

4.1 Application of intelligent technology

With the continuous development of artificial intelligence technology, fully automatic coating machines will pay more attention to intelligent applications. Future coating machines will be able to achieve a more intelligent coating process through learning algorithms and big data analysis, adapting to the needs of different materials and processes.

4.2 Multifunctional coating system

In the future, fully automatic coating machines will pay more attention to versatility and can adapt to different coating needs. For example, it has the switching function of multiple coating systems, which can realize rapid replacement of coating materials and improve production flexibility.

4.3 Environmental protection and energy saving

Against the background of increasing global environmental awareness, future coating machines will pay more attention to environmental protection and energy conservation. Use more environmentally friendly coatings and drying technologies to reduce the impact on the environment and meet the requirements of sustainable development.

4.4 Internet + Coating

The fully automatic coating machine will be combined with Internet technology to realize remote monitoring and management of the coating process. Through the cloud platform, production companies can understand the operating status of the coating machine in real time, perform troubleshooting and maintenance in a timely manner, and improve the stability and reliability of the equipment.

in conclusion

As an advanced coating technology, the fully automatic coating machine has achieved remarkable application results in many fields. Its highly automated and precise control features enable production companies to improve production efficiency, reduce paint waste, and improve coating quality.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative