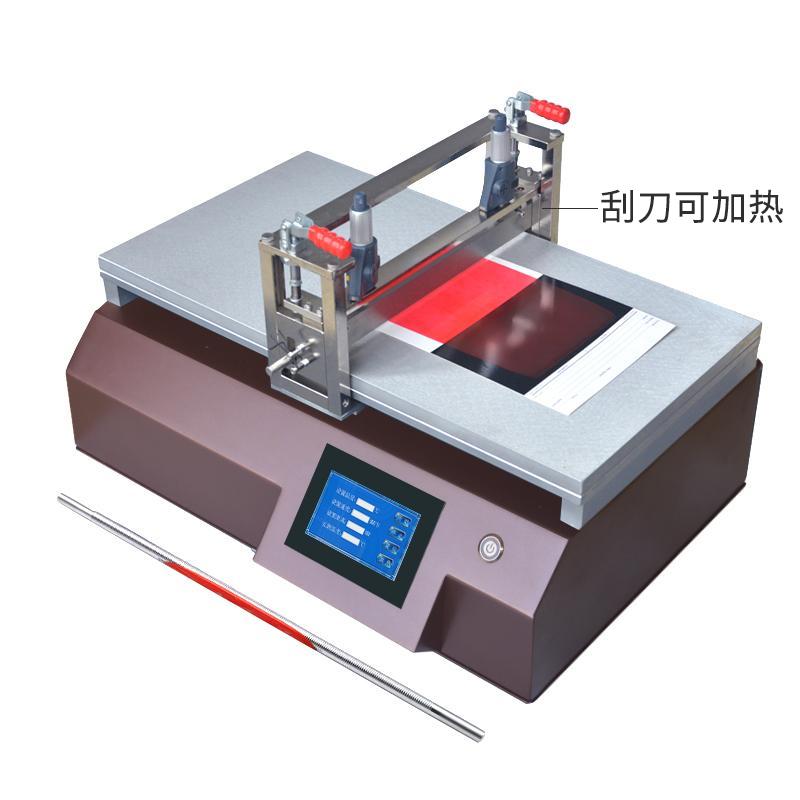

Resin hot-melt adhesive coater technology depth analysis

As a key manufacturing equipment, the resin hot melt adhesive coating machine is widely used in various fields to provide efficient and flexible coating solutions for industrial production. This article will deeply explore the working principle, technical characteristics and application of resin hot melt adhesive coating machines in different industries, aiming to provide readers with a comprehensive and in-depth understanding and understanding.

introduction

With the continuous development of the manufacturing industry, resin hot melt adhesive coating machines, as an important coating technology, have received widespread attention. Its efficient and precise coating process plays an irreplaceable role in textile, packaging, automobile, electronics and other industries.

working principle

The resin hot-melt adhesive coating machine achieves rapid coating and solidification of resin hot-melt adhesive through the collaborative work of the coating system, control system and glue supply system. The coating system melts the resin hot melt adhesive through heating, and the coating head evenly coats it on the surface of the workpiece, and finally solidifies quickly through the cooling system. The control system monitors and adjusts coating parameters in real time to ensure coating stability and quality. The glue supply system is responsible for providing a continuous supply of resin hot melt glue to ensure uninterrupted coating process.

Technical features

The resin hot melt adhesive coating machine adopts an efficient heating system and rapid cooling technology, which can complete coating and solidification in a short time, improving production efficiency while saving energy.

The coating head is precisely designed to achieve precise coating on the surface of the workpiece, ensuring uniform coating thickness and improving product quality and appearance.

The control system adopts advanced automation technology, which can realize automatic control and monitoring of the coating process, reduce manual intervention, and improve the stability of the production line.

The resin hot melt adhesive coating machine is suitable for different types of resin hot melt adhesives. It has strong applicability and can meet the coating needs of different industries.

Applications in different industries

Textile industry: Resin hot melt adhesive coating machines play a key role in the bonding, compounding and cutting processes of textiles, improving the strength and durability of textiles.

Packaging industry: In the packaging industry, resin hot melt adhesive coating machines are used for gluing packaging boxes, cartons, etc. It is fast and strong, improving packaging efficiency and quality.

Automotive industry: Resin hot melt adhesive coating machines are widely used in automotive interiors, body assembly and other fields, improving the bonding quality and production efficiency of automotive parts.

Electronics industry: In electronic product manufacturing, resin hot melt adhesive coating machines are used for fixing and encapsulating electronic components to ensure the stability and reliability of electronic products.

in conclusion

As a key coating technology, resin hot melt adhesive coating machine plays an irreplaceable role in many industries. Its efficient and precise coating characteristics make it an important tool in industrial production. By in-depth understanding of its working principles and technical characteristics, manufacturing companies can better utilize resin hot melt adhesive coating machines to improve production efficiency and product quality.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative