Analysis of Hot-melt adhesive Automatic Film Applicator Technology: Principle, Structure, Operation and Application

Summary

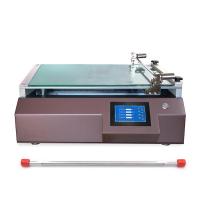

The hot melt adhesive coating testing machine is a professional equipment used to evaluate the coating performance of hot melt adhesive under different conditions. This article will deeply explore the technical principles, structural composition, operating procedures and importance of hot melt adhesive coating testing machines in different application fields. By introducing in detail the characteristics and advantages of this advanced equipment, it will help to gain an in-depth understanding of the development trends and future application prospects of hot melt adhesive coating technology.

Chapter 1: Introduction

1.1 Background

Hot melt adhesives are widely used in modern industry, and their bonding properties depend on multiple factors during the coating process. In order to better understand and optimize the coating performance of hot melt adhesive, the hot melt adhesive coating testing machine came into being. The device provides researchers with an effective tool for evaluating the coating performance of different hot melt adhesives under different conditions by simulating actual coating conditions.

1.2 Purpose

The purpose of this article is to deeply explore the technical principles, structural composition, and operating procedures of the hot melt adhesive coating testing machine, and to explore its applications in different fields. Through a comprehensive analysis of the hot melt adhesive coating testing machine, we can better understand the role of this equipment in the research and development of hot melt adhesive technology and provide strong support for future research.

Chapter 2: Technical Principles

2.1 Coating principle

The coating principle of the hot melt adhesive coating testing machine is based on the fact that the hot melt adhesive changes to a liquid state after being heated, and is then evenly coated on the required substrate through the coating system. The coating process is affected by multiple parameters such as temperature, pressure, and coating speed. The hot melt adhesive coating testing machine simulates different coating conditions in actual applications by controlling these parameters.

2.2 Temperature control system

The coating performance of hot melt adhesive is closely related to temperature, so the hot melt adhesive coating testing machine is equipped with an advanced temperature control system. The system can accurately control the temperature during the coating process to ensure that the hot melt adhesive is coated within the most appropriate temperature range, thereby improving coating quality and efficiency.

2.3 Pressure control system

During the coating process, appropriate pressure is the key factor to ensure coating uniformity. The hot melt adhesive coating testing machine is equipped with a high-precision pressure control system, which can automatically adjust the pressure according to different coating requirements to ensure that the hot melt adhesive can evenly adhere to the substrate during the coating process.

Chapter 3: Structural Composition

3.1 Main structure

The main structure of a hot melt adhesive coating testing machine usually includes heating system, coating system, temperature control system, pressure control system and other main components. The heating system is responsible for heating the hot melt adhesive to a liquid state, and the coating system is used to evenly coat the liquid hot melt adhesive on the substrate. The temperature control system and the pressure control system work together to ensure precise control of the coating process.

3.2 Coating system

The coating system is a key component of the hot melt adhesive coating testing machine. Its structure usually includes a coating head, coating roller, etc. The coating head affects the thickness and uniformity of the coating layer by controlling the width and shape of the coating opening. The coating roller achieves coating by rotating, and the material and treatment method of its surface also have an important impact on the coating effect.

3.3 Control system

The control system of the hot melt adhesive coating testing machine is the intelligent core of the entire equipment, usually using advanced PLC (programmable logic controller) and touch screen interface. Through the control system, operators can easily set coating parameters such as temperature, pressure, and coating speed to achieve precise control of the coating process.

Chapter 4: Operational procedures

4.1 Preparation

Before conducting the coating test, a series of preparations need to be carried out on the hot melt adhesive coating testing machine. Including checking the status of each part of the equipment to ensure that all systems are operating normally; preparing the required hot melt adhesive and substrate and ensuring that they meet the test requirements.

4.2 Parameter settings

Through the control system, the operator can set the relevant parameters of the coating test, such as temperature, pressure, coating speed, etc. The settings of these parameters will directly affect the test results, so they need to be reasonably adjusted according to the specific research purposes and requirements.

4.3 Conduct coating test

Once the parameters are set, the operator can start the hot melt adhesive coating testing machine for testing. During the test process, the equipment will coat according to preset parameters, while monitoring the coating quality and coating layer thickness in real time to ensure the accuracy of the test results.

4.4 Data analysis and recording

After the test is completed, the test data needs to be analyzed and recorded in detail. By analyzing the test results, the coating performance of hot melt adhesive under different conditions can be obtained, providing a reference for further optimizing the hot melt adhesive formula and coating process.

Chapter 5: The Importance of Hot Melt Adhesive Coating Testing Machines in Different Application Fields

5.1 Packaging industry

In the packaging industry, hot melt adhesive is widely used in processes such as box sealing and glue sealing. The hot melt adhesive coating testing machine can help the packaging industry study the coating performance of different types of hot melt adhesives on high-speed production lines and improve sealing strength and production efficiency.

5.2 Automobile manufacturing

In the automobile manufacturing process, hot melt adhesive is used in key links such as body assembly and sealing. Through the hot melt adhesive coating testing machine, the uniformity of hot melt adhesive coating can be optimized and the bonding strength and durability of automotive components can be improved.

5.3 Textile industry

In the textile industry, hot melt adhesive coating testing machines can be used to study the performance of different hot melt adhesives in waterproofing, windproofing and other properties of textiles. By optimizing the coating process, the functionality and adhesion of textiles can be improved.

5.4 Electronics industry

In the electronics industry, hot melt adhesive coating testing machines play a key role in the packaging and fixation of electronic components. By studying the coating effects of different hot melt adhesives on the surface of electronic devices, the reliability and stability of electronic products can be improved.

Chapter 6: Conclusion

As an advanced research equipment, the hot melt adhesive coating testing machine plays an important role in deeply understanding the coating performance of hot melt adhesive and optimizing the coating process. Through a detailed introduction to its technical principles, structural composition, and operating procedures, this article aims to provide researchers with a more comprehensive understanding and provide strong support for the development of hot melt adhesive technology.

- 1Lab Film Applicator Application Case of applying water-based paints on paper [with experimental video]

- 2Experimental Application Technology of Resin Film Prepared by Spreader

- 3Technical introduction of hot-melt adhesive coater

- 4Application of laboratory coater in EVA hot-melt adhesive

- 5Application and Technological Innovation of Coater Scratching Hot-melt Adhesive on PET Film

- 6Analysis and application of non-woven hot-melt adhesive coater technology

- 7Comparison between hot-melt adhesive double-sided coater and hot-melt adhesive coil coater

- 8Fiberglass hot-melt adhesive coater technical analysis and operation guide

- 9Application and advantage analysis of Lab Film Applicator in solder paste film