Experimental Film Applicators: Guidelines for Selection, Operation and Application

Summary

This article aims to deeply discuss the technical characteristics, selection methods and operation methods of experimental film coating machines, and provide comprehensive understanding and guidance for scientific researchers and engineers. Experimental coating machines play a vital role in research in various fields, and their precise coating processes are of great significance to material research, electronic device preparation, etc. The article will be divided into three main parts. First, the technical characteristics and application fields of the experimental film coating machine will be introduced, then the selection method will be discussed in detail, and finally the operating methods and precautions will be discussed in depth.

1. Technical characteristics and application areas of experimental film coating machines

1.1 Technical features

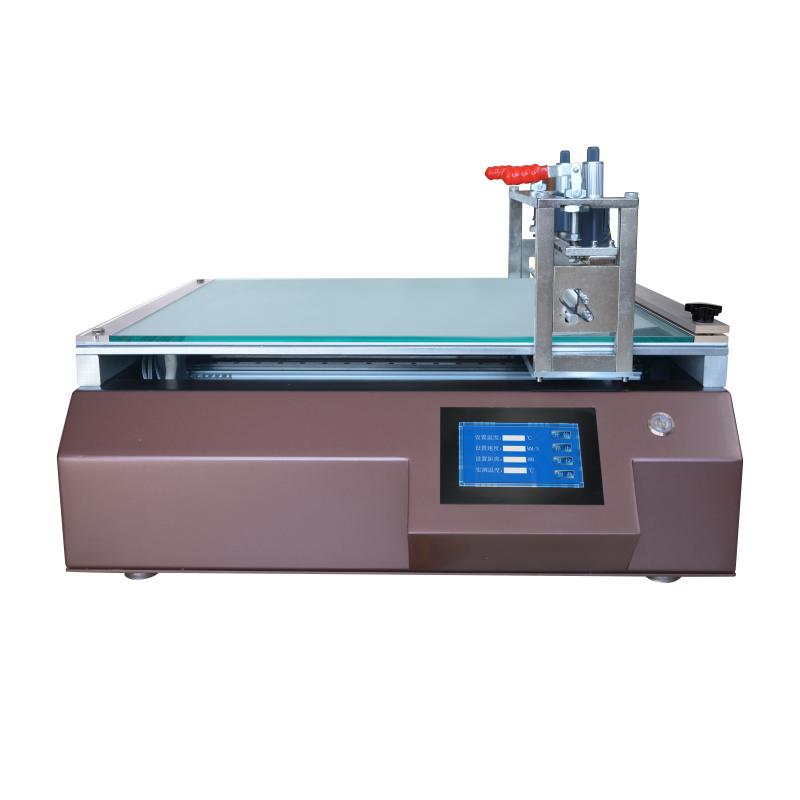

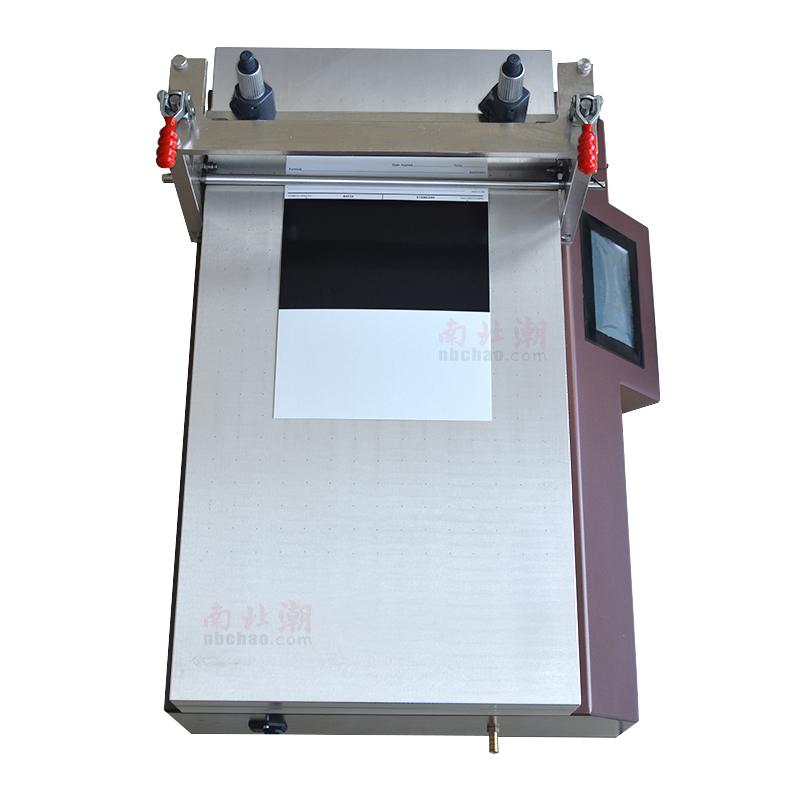

The experimental film coating machine is a device used to evenly coat thin films on the surface of materials. Its main technical features include:

1.1.1 Precision control system: The experimental coating machine is equipped with an advanced coating control system, which can achieve precise control of key parameters such as coating thickness and uniformity.

1.1.2 Multifunctional coating head: Film coating machines are usually equipped with different types of coating heads, which can be applied to different coating materials and application scenarios.

1.1.3 High vacuum environment: For some special materials, the experimental film coating machine can apply the film in a high vacuum environment to ensure the purity and stability of the material.

1.1.4 Automated control: Modern experimental film coating machines usually adopt automated control systems, which can realize a fully automatic coating process and improve experimental efficiency.

1.2 Application areas

Experimental film coating machines are widely used in various fields, mainly including but not limited to the following aspects:

1.2.1 Material research: In the laboratory, new materials often need to be coated to change their surface properties. The experimental coating machine can provide a highly controllable coating process to meet the needs of scientific research.

1.2.2 Optical coating: In the preparation of optical devices, experimental coating machines can be used in the preparation of optical coatings to improve the performance and stability of the device.

1.2.3 Preparation of electronic devices: In the preparation process of semiconductors, optoelectronic devices, etc., experimental film coating machines can achieve precise coating of thin films and improve the performance of the devices.

1.2.4 Thin film research: For the research of thin film materials, experimental film coating machines can provide a reliable experimental platform for the growth and characterization of thin films.

2. Selection method of experimental film coating machine

2.1 Selection based on coating material

When selecting an experimental coating machine, you must first consider the type of coating material. Different coating materials require different types of coating heads and coating systems. Common coating materials include metals, semiconductors, ceramics, etc. Choosing a suitable coating machine is crucial to obtaining high-quality coatings.

2.2 Selection based on coating thickness and uniformity requirements

Different application scenarios have different requirements for coating thickness and uniformity, so the ability of the experimental coating machine to control these parameters needs to be considered when selecting. Some high-end coating machines are equipped with advanced control systems that can achieve nano-level coating thickness control and uniformity control.

2.3 Consider the experimental environment and scale of the experiment

The experimental environment and experimental scale in the laboratory are also important considerations in model selection. Some experimental film coating machines need to operate in a high vacuum environment, while others can apply film under normal temperature and pressure conditions. In addition, some large-scale experiments require high-throughput coating capabilities, while small-scale experiments can choose a simpler experimental coating machine.

2.4 Consider budget and maintenance costs

The prices and maintenance costs of experimental coating machines vary greatly, so the laboratory's budget needs to be considered when selecting. At the same time, it is necessary to evaluate the ease and maintenance cost of the equipment to ensure long-term stable operation of the equipment.

3. Operation methods and precautions of experimental film coating machine

3.1 Operation method

The operation method of experimental film coating machine generally includes the following steps:

3.1.1 Equipment preparation: Ensure that all components of the coating machine are in normal working condition, including coating head, vacuum system, control system, etc.

3.1.2 Sample preparation: Place the sample to be coated on the sample stage and ensure that the sample surface is clean and free of impurities.

3.1.3 Parameter setting: According to the coating material and requirements, set the parameters of the coating machine, including coating speed, vacuum degree, working temperature of the coating head, etc.

3.1.4 Coating process: Start the coating machine and start the coating process. The coating thickness and uniformity can be monitored in real time during the coating process and adjusted as needed.

3.1.5 Coating completion: After coating is completed, stop the coating machine and remove the sample for subsequent processing or analysis.

3.2 Things to note

During the operation of the experimental film coating machine, the following matters need to be paid attention to:

3.2.1 Safe operation: Operators should strictly abide by the safety regulations of the film coating machine to ensure safe operation in a high vacuum environment and avoid accidents.

3.2.2 Coating material selection: Select the appropriate coating material according to the experimental requirements to ensure that the quality and performance of the coating meet the experimental requirements.

3.2.3 Parameter adjustment: During the coating process, the coating thickness and uniformity need to be monitored at any time, and parameter adjustments should be made based on real-time data to ensure coating quality.

3.2.4 Equipment maintenance: Regularly maintain the coating machine, clean the coating head, check the vacuum system, etc. to ensure long-term stable operation of the equipment.

in conclusion

As a key experimental equipment, experimental coating machines play an important role in materials research, device preparation and other fields. When selecting, factors such as coating material, thickness and uniformity requirements, experimental environment and scale, budget, etc. need to be considered to ensure that appropriate equipment is selected. During operation, pay attention to safe operation and parameter adjustment during the coating process, and perform regular equipment maintenance to ensure long-term stable operation of the equipment. By having an in-depth understanding of the technical characteristics and operating methods of experimental coating machines, scientific researchers and engineers can better utilize this advanced equipment to conduct coating experiments and promote the development of scientific research and technological innovation.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Film Applicator in PEM Research and Preparation

- 8Application of Film Applicator in PVDF-HFP Material Research

- 9Application of Film Applicator in Cosmetic Base Body