EVA Resin coater technology and operation method detailed explanation

introduction

EVA (ethylene vinyl acetate copolymer) resin coating machines play a vital role in modern industrial production and are widely used in shoe materials, packaging, construction and other fields. This article will delve into the technical principles, coating machine types, operating methods, etc. of EVA resin coating machines in order to better understand this key industrial equipment.

Technical principles

1. Overview of EVA resin

EVA resin is a thermoplastic with excellent properties such as elasticity, cold resistance, chemical resistance and processability. Through the coater, EVA resin can be evenly coated on the substrate, giving the substrate specific properties.

2. Coating machine type

2.1 Roller coater

Roller coater is one of the common types of EVA resin coater. The basic principle is to evenly coat the EVA resin on the surface of the substrate through the rotation of the roller. This coating machine has a simple structure and is easy to operate, and is suitable for large-area coating.

2.2 Spray coating machine

The spray coater uses high-pressure gas to spray EVA resin onto the substrate to form a uniform coating. This method is suitable for occasions that require higher coating quality to achieve more detailed coating.

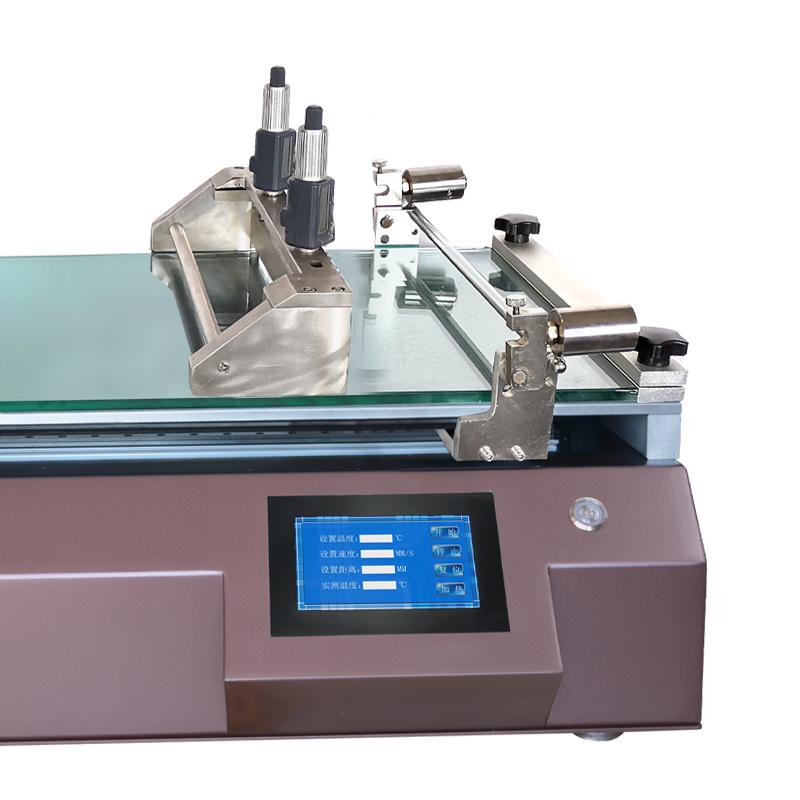

2.3 Blade coater

The blade coater uses a blade to evenly coat EVA resin on the substrate, and is suitable for substrates with high coating thickness requirements or special shapes.

3. Operation method

3.1 Preparation

Before operating the EVA resin coating machine, a series of preparations are required, including checking various parts of the coating machine, adjusting parameters, preparing EVA resin and substrate, etc.

3.2 Adjust parameters

According to the type of coating machine, adjust coating speed, temperature, coating thickness and other parameters. These adjustments are directly related to the coating effect and product quality, and require experienced operators to set them up.

3.3 Start the coating machine

When starting the coating machine, ensure that each system is operating normally and check the status of the coating head, roller, scraper and other components. Select the start mode and gradually increase the coating speed.

3.4 Monitor the coating process

During the coating process, the coating effect is continuously monitored, and the coating machine parameters are adjusted by observing the coating head and coating thickness to ensure uniform and stable coating.

3.5 Shutdown and cleaning

After the coating work is completed, stop the machine in time and clean it. Cleaning includes the coating head, removing residual EVA resin, keeping the coating machine clean, and preparing for the next production.

Advantages and application areas

1. Advantages

1.1 Efficient production

The EVA resin coating machine has high coating speed and high production efficiency, adapting to the needs of mass production.

1.2 Even coating

Regardless of the type of coating machine, the technical principles and operating methods ensure uniform coating of EVA resin and ensure product quality.

1.3 Diversified applications

The EVA resin coating machine is suitable for various substrates, such as paper, cloth, plastic, etc. The parameters can be adjusted according to needs to achieve diversified applications.

2. Application areas

2.1 Shoe material manufacturing

It is widely used in shoe material manufacturing to make soles, insoles, etc. to improve the elasticity and wear resistance of footwear products.

2.2 Packaging industry

EVA resin coating machine is used for coating packaging materials to improve the durability and appearance quality of packaging materials.

2.3 Construction field

In the field of construction, it is used to produce waterproof materials, such as waterproof membranes, to improve the waterproof performance of building materials.

in conclusion

As a key industrial equipment, EVA resin coating machine is widely used in shoe materials, packaging, construction and other fields. Different types of coating machines have certain technical principles and operating methods, but they can all achieve uniform coating of EVA resin on the substrate. In the future, EVA resin coating machines will continue to give full play to their advantages of efficient and uniform coating, providing reliable solutions for industrial production.

- 1Kinetic control of silicon carbon cathode Spreader drying: key technology to solve crazing and powder drop

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Application of doctor blade coater in electrode and solid electrolysis preparation

- 4Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 5Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 6Several Common Experimental Spreader Methods and Their Applications

- 7Application of laboratory coater coating aluminum oxide paste on PET film

- 8Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 9Method and application of experimental coater coating water-based slurry on aluminum foil