Small laboratory coaters: technical principles, species comparison and application

Summary:

This article will introduce in detail the technical principles, type comparison and application fields of small laboratory coaters. Small laboratory coaters play an important role in scientific research, education and product development. The article will deeply explore the structure, working principles, advantages and disadvantages, and application scope of different types of small laboratory coating machines, with a view to providing scientific researchers with comprehensive technical understanding and experimental guidance.

Part One: Introduction

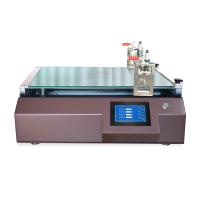

A small laboratory coater is a piece of equipment designed for laboratory-scale coating operations. Its main function is to simulate industrial coating processes for the preparation of coatings, films and composite materials. Compared with large-scale production coating machines, small laboratory coating machines have the advantages of small size, easy operation, and suitable for a variety of coating materials. Therefore, they are widely used in scientific research and teaching fields.

Part 2: Technical Principles

The technical principles of small laboratory coating machines mainly include coating system, laminating system, auxiliary system and control system.

Coating system: The coating system is the core part of a small laboratory coating machine, usually including a coating head, coating roller, coating knife, etc. The coating head can realize different coating methods through different designs, such as roller coating, blade coating, etc. The coating roller spreads the coating evenly on the substrate through rotating motion, while the coating knife is used to adjust the thickness of the coating layer.

Laminating system: The laminating system ensures that the coating is tightly adhered to the substrate and generally consists of a pressure roller/tension control device. The pressure roller ensures a firm bond between the coating and the substrate through a certain amount of pressure, while the tension control device is used to adjust the tension of the substrate (for coil coaters) to ensure the smooth progress of the entire coating and lamination process.

Auxiliary system: The auxiliary system includes temperature control, speed control, etc. to ensure the stability of parameters during the coating and lamination process. Temperature control is particularly important for some coatings that need to be dried or cured, while speed control is related to coating uniformity.

Control system: The control system is the brain of the small laboratory coating machine and is responsible for coordinating the work of the coating system, laminating system and auxiliary system. Modern coating machines usually use PLC (programmable logic controller) or microcontroller to achieve efficient control.

Part 3: Comparison of types of small laboratory coating machines

Small laboratory coaters can be divided into different types according to different coating methods and coating materials, including roller coaters, blade coaters, spray coaters, etc.

Roller coater: The roller coater uses the rotation of the coating roller to evenly coat the coating on the substrate. This coating method is suitable for thicker coatings and can achieve higher coating speeds. However, due to the limitations of the roller, it is not suitable for coatings that are too thin.

Blade coater: The blade coater uses a scraper to smooth the paint to form a uniform coating. This method is suitable for experiments requiring thinner coatings and has better adaptability to high-viscosity coatings. However, the uniformity of blade coating is affected by blade angle and pressure.

Spray coater: A spray coater sprays paint evenly onto the substrate through a nozzle. This method is suitable for some experiments that require thin and uniform coatings, and is also more flexible in the choice of coatings. However, spray coaters can be affected by issues such as airflow and clogged nozzles.

Part 4: Application areas

Small laboratory coaters are widely used in scientific research, teaching, product development and other fields. Specifically include but not limited to:

Material research: used to prepare various functional films and coatings, such as optoelectronic materials, electronic materials, etc.

Medical field: used to prepare biomedical materials, such as medical laminating films, drug release films, etc.

Food packaging: used to prepare packaging materials with functions such as moisture-proof, oxygen-proof, and fresh-keeping.

Part Five: Conclusion and Outlook

Through an in-depth discussion of the technical principles, type comparison and application fields of small laboratory coating machines, we can see the importance and broad application prospects of this technology in various fields. As a key tool to support this technology, the small laboratory coater's continuous technological innovation and development will provide researchers in related fields with more advanced and efficient experimental methods and promote the continuous progress of coating and laminating technology. In the future, with the development of science and technology, small laboratory coating machines will be more intelligent and multi-functional, meeting the higher requirements for coating technology in different fields.

- 1Application of laboratory coater in LED fluorescent film Spreader

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 4Application of doctor blade coater in electrode and solid electrolysis preparation

- 5Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 6Experimental application of water-based paints on film laminating paper by laboratory coater

- 7Experimental coater application case video of liquid silica gel on release paper

- 8Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 9Technical Requirements and Application of Lithium Battery Slurry Coated on Copper Foil for Small Coater