Overview of film coater technology and process requirements

introduction

With the continuous development of science and technology, film coating technology is increasingly used in various industries. As the key equipment, the film coating machine plays an important role. This article will review the basic principles, technical characteristics, application fields and related process requirements of film coating machines, in order to gain a deeper understanding of the technological progress in this field.

1. Basic principles of film coating machine

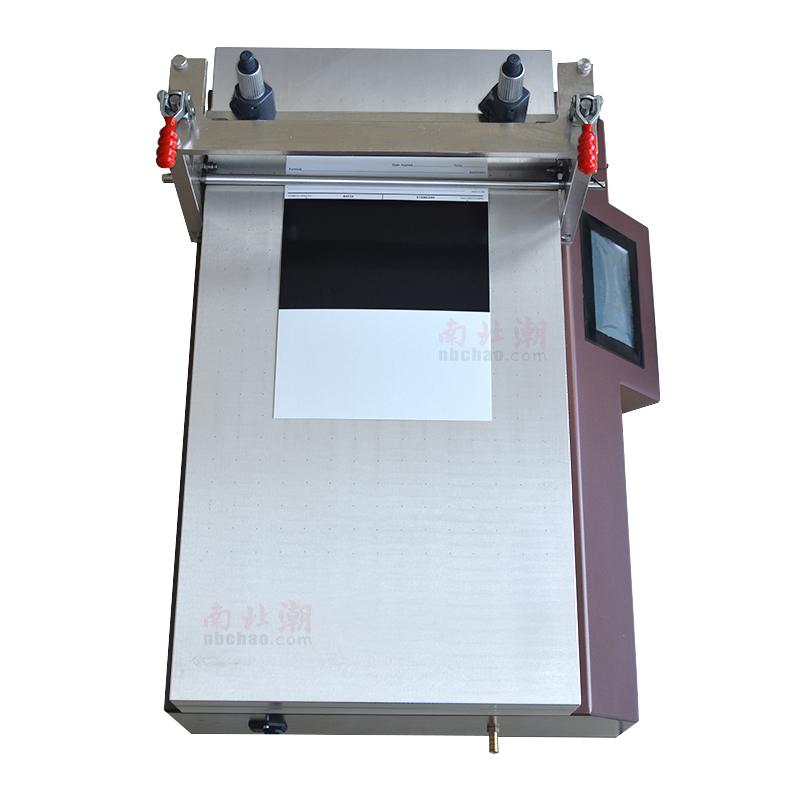

The adhesive Film Applicator is a device for coating thin film materials. Its basic principle is to evenly coat the adhesive film on the surface of the substrate through rollers, scrapers or other coating devices. Adhesive films are usually made of rubber, polymers and other materials, and their selection depends on the specific requirements and application scenarios of the coating.

The core of the coating machine is the coating head, whose structure usually includes rollers, coating rollers, scrapers and other components. The roller is used to support and transfer the film material, while the coating roller is responsible for evenly coating the adhesive film on the substrate. The scraper plays a role in controlling the thickness of the coating film to ensure the uniformity of the coating.

2. Technical characteristics

1. High-precision control

Modern film coating machines have high-precision coating control systems that use advanced sensors and automation technology to achieve precise adjustment of coating thickness, speed and other parameters. This high-precision control not only improves production efficiency, but also ensures consistency in coating quality.

2. Multifunctional applicability

The film coating machine can not only be used on traditional paper, plastic film and other substrates, but can also be widely used for coating special materials such as conductive films, optical films, etc. This multifunctional applicability makes it widely used in electronics, optics, printing and other fields.

3. High efficiency and energy saving

Modern film coating machines pay more attention to energy efficiency in design, and use advanced drive technology and energy recovery devices to achieve high efficiency while reducing energy consumption. This is in line with contemporary industryâs pursuit of green manufacturing.

3. Application fields

Film coating machines play an important role in various industries and are mainly used in the following fields:

1. Packaging and printing

Film coating machines are widely used in the packaging and printing industry. By coating a special film on the surface of packaging materials, they can improve the wear resistance, waterproofness and gloss of the printed matter, while also achieving a beautiful effect on the packaging.

2. Electronics industry

In the electronics industry, film coating machines are often used to coat conductive films for the production of electronic components, displays, etc., to improve their conductive performance and durability.

3. Optical field

Film coating machines are widely used in the optical field and can coat various optical films, such as anti-reflective films, reflective films, etc., to improve the performance and transparency of optical elements.

4. Automobile manufacturing

In automobile manufacturing, Film Applicators are often used to coat protective films on the car body surface to improve the wear resistance and corrosion resistance of the car surface.

4. Film coating process requirements

1. Substrate surface treatment

Before coating, the surface of the substrate must be properly treated to ensure it is clean, flat, and has a certain surface tension. This helps improve coating adhesion and consistency.

2. Coating thickness control

The key to the film coating machine is precise control of coating thickness. Therefore, the process requirements must include a real-time monitoring and adjustment mechanism for the coating thickness to ensure the uniformity and stability of the coating layer.

3. Temperature and humidity control

The ambient temperature and humidity during the coating process have an important impact on the coating effect. The process requirements must include temperature and humidity control requirements for the coating workshop to ensure stable coating effects in different seasons and environmental conditions.

4. Coating speed adjustment

Different substrates and coating materials may require different coating speeds, so the Film Applicator should have the adjustability of the coating speed to adapt to different materials and process requirements.

5. Cleaning and maintenance

Regular cleaning and maintenance is the key to ensuring the normal operation of the film coating machine. Cleaning process requirements should include regular cleaning of key components such as coating rollers and scrapers to prevent the accumulation of impurities from affecting the coating effect.

5. Conclusion

Film coaters are widely used in various fields. Its technical features such as high-precision control, multi-functional applicability and high efficiency and energy saving make it an important tool for improving production efficiency, product quality and reducing costs. At the same time, the strict requirements for the film coating process are also an important guarantee for ensuring the coating effect. It is hoped that with the continuous advancement of science and technology, film coating machine technology will become more mature and bring more convenience and possibilities to various industries.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative