The Film Applicator You Think Is Not What You Think

Friends in the coating field all know about coating machines, and they also know that coating machines are platform equipment that replace manual automatic scraping. Those who know more about coatings also know that the precision thickness of coatings is not mainly controlled and determined by coating machines. , the film thickness is controlled by a matching wire rod or scraper

From this point of view, the film coating machine is a film coating equipment that controls the speed and pushes the wire rod/scraper to scrape the film. The principle is very simple and is almost the same. If you want high accuracy, just choose a high-precision wire rod or scraper. . However, the Film Applicator you think is not what you think it is.

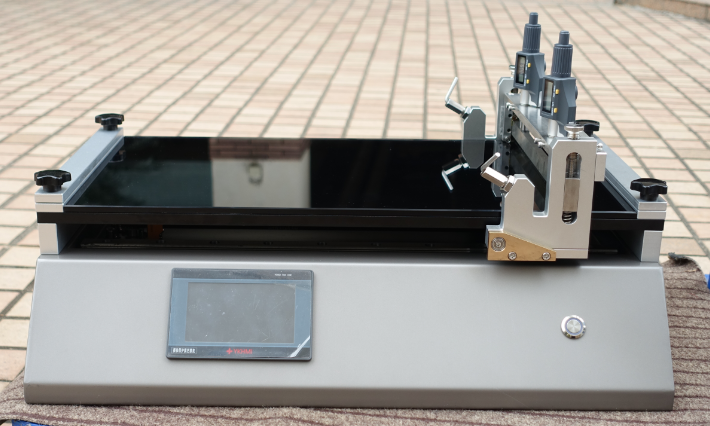

Film coating machine equipment picture 1

In Figure 1 of the coating machine equipment above, what you may see is: a wire bar adjustable scraper coating machine, a glass platform, a control panel, switches, and fixtures. It looks pretty good, but in the end it is all. Itâs almost like that. Many of them are the ones we look for at the lowest price.

Today, the editor will take you to explore what is behind a truly high-precision and high-efficiency coating machine?

The ultimate purpose of coating film proofing is to test product quality or optimize and improve product quality through testing. The accuracy of a coating sample has a great impact on subsequent testing, especially for new materials and high-end precision industrial products. For experimental technicians, the requirements for film production and proofing are nothing more than high-efficiency proofing and high-precision film production .

First, a good film coating machine allows you to make prototypes really efficiently .

If you choose to use a film coating machine instead of proofing, at least you are taking the first step to solve the problem of coating efficiency. Then, next you will encounter new efficiency problems, the installation efficiency and cleaning efficiency of the Film Applicator.

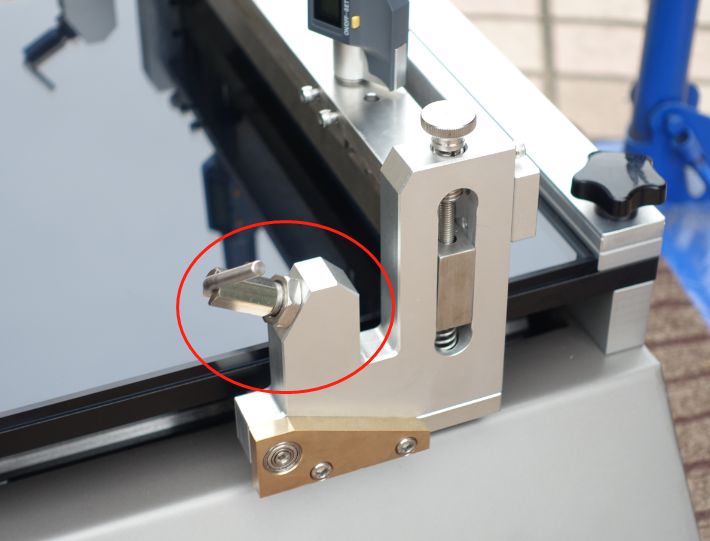

Zoom in on the details of the picture above and take a look at this device. The design of the efficient coating machine is truly designed from the user's perspective: 1. Snap-on wire bar installation. On the one hand, installation and disassembly are very simple. On the other hand, this installation method greatly reduces the possible damage caused by wire bar loading and unloading. of wear and tear.

2. Flip-top scraper design. Cleaning is no longer a confusing issue for scraper coating. For fixed and adjustable scrapers, cleaning is much more efficient without losing the original stability of fixed drum scrapers.

3. The clamp that fixes the base material on the right side of the picture above also has a hidden secret. It has a built-in spring and is more efficient in fixing the base material. It can be clamped by simply turning it a few times (details are not included here).

Have you compared these details?

Second, the best coating machine ensures high-precision coating in all aspects

Anyone who knows something about coating machines knows that high-precision coating must be equipped with high-precision coating equipment, such as imported wire rod coaters and scrapers with higher precision. So, is this enough? Just like a computer, the CPU is the core, and a good CPU will definitely run faster. But wonât the hard drive be affected ? Doesn't memory size matter? Are the network and hardware not affected?

So the film coating machine you think is really not that simple. The same is true for film coating machines. The accuracy of the film coating machine is the key, but the flatness of the base plate of the coating machine itself, the accuracy of the blade thickness control, the stability of the motor operation, the flatness of the base material fixation, and even the adjustment of the entire equipment The level of the coating will affect the accuracy of the coating.

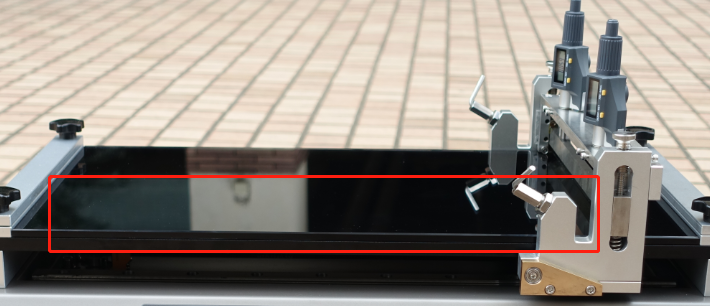

Letâs enlarge the film coating machine equipment picture 1 above and take a look. The black glass plate above is a selected 3C certified national standard genuine high-flatness Jinjing original high-temperature tempered glass plate, which ensures the accuracy of the flatness of the coating platform.

Then shift your attention to the adjustable scraper on the right. The differential regulator that controls the thickness of the scraper is selected from a brand with trustworthy quality. The scraper below has been tested for accuracy by professional precision measurement equipment and comes with a certificate.

In addition, there is also something we cannot see, the choice of the motor of the equipment. A good motor has relatively high operating stability, which also has an impact on the accuracy of the coating film. To give a simple example, if the motor vibration is obvious, the scraped film will have ripples, or the thickness of the scraped coating will be uneven. This is why experiments that require higher coating accuracy will choose higher-priced servo motors.

All in all, the film coating machine does not simply control the speed and pressure, and then push the Film Applicator for scraping coating to easily obtain high-precision film samples. Itâs hard to make a meal without rice, and no matter how experienced a technical expert is, he still needs a good tool to help him. There is such a truth in the field of testing instruments: the quality level of the testing equipment you use can often reflect the quality level of your products. Therefore, within a limited budget, it is more ideal to choose more cost-effective equipment. I hope this article will inspire you in choosing film coating machine equipment.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Laboratory Automatic Film Applicator in Coating Battery Slurry on Copper Foil and Aluminum Foil

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research