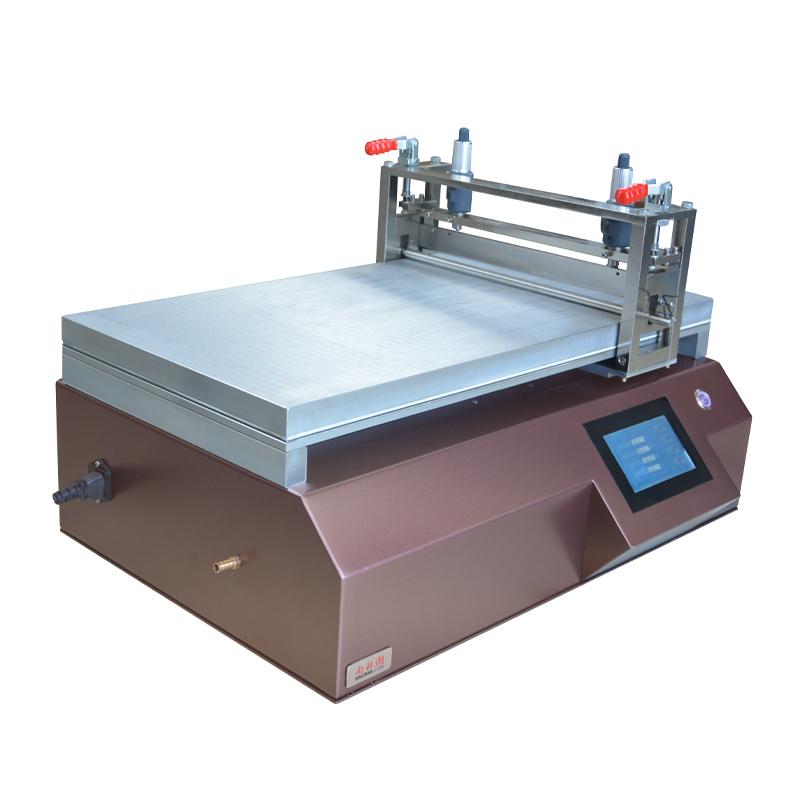

Double-sided tape coater: Selection and Troubleshooting Guide

introduction

The double-sided tape coating machine is a piece of equipment widely used in industrial production. It can evenly coat the glue on the materials on both sides to ensure a stable and reliable bonding effect. This article will delve into the selection methods and common faults of double-sided adhesive coating machines, and provide solutions to help engineers and operators better understand and deal with related technical challenges.

1. Selection method of double-sided tape coating machine

1.1 Material requirements

When choosing a double-sided tape coating machine, you must first consider the material to be coated. Different materials may require different types of coating machines. For example, for different materials such as paper, film or metal plates, the appropriate coating machine model should be selected based on their surface characteristics and adsorption properties.

1.2 Production speed requirements

Production speed is one of the key factors in choosing a coating machine. Different models of coating machines have different production speeds. The appropriate model should be selected according to the needs of the production line to ensure production efficiency and product quality.

1.3 Coating width and uniformity

The coating width of the double-sided tape coater is another factor to consider. According to the actual application requirements, select the appropriate coating width and pay attention to the uniformity of the coating machine to ensure uniform coating quality.

1.4 Degree of automation

As the level of industrial automation increases, many companies prefer to choose double-sided tape coating machines with highly automated functions. Equipment with a higher degree of automation can improve production efficiency, reduce manual intervention, and reduce labor costs.

1.5 Equipment stability and maintainability

Equipment stability and maintainability are crucial to the continued operation of the production line. Choosing a coating machine with strong stability and easy maintenance can reduce the probability of failure and improve the reliability of the equipment.

1.6 Energy saving and environmental protection

In modern industry, energy conservation and environmental protection have become an important consideration. Choosing a double-sided tape coating machine with lower energy consumption and more environmentally friendly waste disposal can help enterprises reduce energy consumption during the production process and reduce the burden on the environment.

1.7 Cost considerations

Finally, cost is also one of the factors that needs to be considered comprehensively when choosing a double-sided tape coating machine. On the premise of meeting the above requirements, choose equipment with moderate price and stable performance to optimize investment.

2. Common faults and solutions

2.1 Uneven coating

Uneven coating may lead to substandard product quality and affect production efficiency. This issue may be caused by:

Uneven glue supply: Check the glue supply system to ensure that the glue flows evenly.

Unbalanced coating roller: Check the installation and adjustment of the coating roller to ensure its balance.

Coating roller wear: Check the wear of the coating roller regularly and replace the coating roller with greater wear in a timely manner.

2.2 Equipment is blocked

Equipment clogging may be caused by drying of glue or mixing of impurities. Solutions include:

Clean equipment regularly: Clean the double-sided tape coating machine regularly to prevent glue from accumulating in the pipes or nozzles.

Choose the right glue: Choose a glue with a moderate drying time to prevent it from drying too quickly in the device and causing clogging.

2.3 Equipment failure alarm

Coating machine equipment is usually equipped with a fault alarm system, but sometimes false alarms or false alarms may occur. Solutions include:

Check the sensor regularly: Check the faulty sensor regularly to make sure it is working properly.

Upgrade the control system: If necessary, consider upgrading the control system of the coating machine to improve the accuracy of fault detection.

2.4 Equipment noise is too loud

Excessive noise will not only affect the working environment, but may also be a signal of equipment problems. Solutions include:

Check equipment parts regularly: Check key parts of your equipment regularly to make sure they are not loose or worn.

Use sound insulation measures: If necessary, use sound insulation materials or sound insulation covers to reduce equipment noise.

2.5 Inaccurate temperature control

For some glues that need to work at specific temperatures, inaccurate temperature control may lead to a decrease in glue performance. Solutions include:

Check the temperature control system regularly: Make sure the sensors and regulators of the temperature control system are working properly.

Calibrate the temperature set value: According to actual needs, regularly calibrate the temperature set value of the coating machine to ensure that the glue works at the appropriate temperature.

in conclusion

As an indispensable piece of equipment in modern industrial production, the double-sided tape coating machine involves many aspects of technical knowledge in its selection and troubleshooting. By carefully selecting the appropriate machine model and taking effective maintenance and troubleshooting measures, you can ensure the stable operation of the coating machine, improve production efficiency, and reduce production costs. At the same time, constantly paying attention to the development of new technologies and updating equipment in a timely manner are also one of the keys for enterprises to maintain competitiveness.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative