Core parameters and operation guidelines for continuous laboratory hot-melt adhesive coaters

introduction

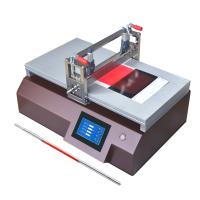

Laboratory hot melt adhesive coating machine is a key equipment used for glue coating in laboratory environment. Its efficient and precise coating function plays an important role in scientific research, testing and small batch production. This article will delve into the core technical parameters and operating methods of the continuous laboratory hot melt adhesive coating machine to help users better understand and give full play to the performance of this equipment.

1. Core technical parameters

1.1 Coating speed

Coating speed is one of the key parameters to measure the performance of hot melt adhesive coating machine. Usually in meters/minute, the choice of coating speed should be determined based on experimental needs and the characteristics of the glue. Higher coating speed can improve experimental efficiency, but coating uniformity and glue curing time must also be taken into consideration.

1.2 Coating width

Coating width refers to the maximum width range of one coating, in millimeters. The choice of coating width should be determined based on the size of the experimental sample to ensure that the coating covers the entire sample surface.

1.3 Temperature control range

The coating effect of hot melt adhesive is greatly affected by temperature, so temperature control is one of the important technologies for laboratory hot melt adhesive coating machines. The temperature control range should be wide enough to accommodate the coating needs of different types of glue.

1.4 Pressure adjustment

Glue pressure during coating is one of the key factors affecting coating uniformity. The hot melt adhesive coating machine should have a pressure adjustment function to meet the coating requirements of different glues and materials.

1.5 Cooling system

After coating, the glue needs to be cooled quickly and evenly to ensure the stability and adhesion of the coating layer. The design and performance of the cooling system are critical to the experimental results.

1.6 Control system

Advanced control systems can provide more operating options and experimental data recording functions. Users can precisely control the coating machine through the control system and monitor various parameters in real time to better understand the experimental process.

2. Operation method

2.1 Preparation

Before conducting experiments, sufficient preparations need to be made for the laboratory hot melt adhesive coater. This includes checking whether the equipment is normal, whether the glue and samples are adequately prepared, etc.

2.2 Parameter settings

According to the experimental requirements, set parameters such as coating speed, coating width, temperature, and pressure. Ensure that the settings of these parameters can meet the requirements of the experiment and avoid experimental failure caused by improper parameter settings.

2.3 Sample preparation

Prepare the sample to be coated, ensuring that the surface of the sample is clean, flat, and meets the dimensions required by the experiment. Note that the surface treatment of the sample may affect the coating effect and requires pretreatment according to experimental requirements.

2.4 Glue coating

Start the hot melt adhesive coating machine and start the experiment. Pay attention to monitoring various parameters during the coating process to ensure uniform and stable coating. Select the appropriate coating mode according to the experimental requirements, such as single-sided coating, double-sided coating, etc.

2.5 Cooling and solidification

After completing the coating, ensure that the coating layer is sufficiently cooled and solidified. This usually takes a certain amount of time, determined according to the nature of the glue and experimental requirements.

2.6 Data recording and analysis

Use the control system of the hot melt adhesive coating machine to record various parameters during the experiment for subsequent data analysis and evaluation of experimental results. This helps optimize experimental procedures and improve experimental design.

2.7 Cleaning and maintenance

After the experiment, clean all parts of the coating machine in time to ensure that the equipment is in good working condition. Perform regular maintenance to check the wear and performance of critical components such as coating rollers, heating elements, and pressure sensors.

in conclusion

Laboratory hot melt adhesive coating machines play an important role in scientific research and experiments, and the mastery of their performance and operating methods is directly related to the accuracy and repeatability of experimental results. By having an in-depth understanding of the core technical parameters and flexible use of operating methods, users can make better use of the laboratory hot melt adhesive coating machine, improve experimental efficiency, and promote the progress of scientific research work. We hope that the content of this article can provide useful guidance and reference for users of laboratory hot melt adhesive coating machines.

- 1Application of laboratory coater in LED fluorescent film Spreader

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Application of doctor blade coater in electrode and solid electrolysis preparation

- 4Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 5Experimental application of water-based paints on film laminating paper by laboratory coater

- 6Experimental coater application case video of liquid silica gel on release paper

- 7Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 8Application of small coater in gel coating

- 9Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane