Technical principle and operation precautions of water-based composite rubber coater

preface

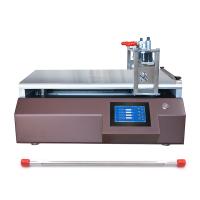

The water-based composite glue coating machine is a piece of equipment widely used in various industries. Its main function is to coat water-based composite glue on the surfaces of different materials to achieve the bonding of various composite materials. This kind of coating machine has important applications in textile, packaging, construction and other fields. This article will introduce in detail the technical principles, operating procedures and precautions of the water-based composite adhesive coating machine.

1. Technical principles of water-based composite adhesive coating machine

working principle

The water-based composite glue coating machine uses advanced coating technology to evenly coat the water-based composite glue on the surface of the substrate through a coating roller. Its working principle mainly includes several key parts such as glue supply system, coating roller, and substrate transportation system. First, the glue is transported from the supply system to the coating roller, and then the coating roller is evenly coated on the passing substrate, finally forming a composite material.

Coating roller design

The coating roller is one of the core components of the water-based composite adhesive coating machine. Its design needs to take into account factors such as the viscosity of the glue, control of the coating amount, and adjustment of the coating width. Generally speaking, coating rollers are usually made of high-quality rubber or other special materials to ensure uniformity and stability of coating.

Control System

The water-based composite adhesive coating machine is equipped with an advanced control system that can accurately adjust parameters such as coating volume, speed, temperature, etc. Through the PLC control system, operators can easily set up and monitor the entire coating process to ensure the quality and production efficiency of composite materials.

2. Operation process of water-based composite adhesive coating machine

1) Preparation work

Before starting the water-based composite adhesive coating machine, the operator needs to perform a series of preparations. Including checking whether the glue supply system is normal, whether the coating roller is clean, whether the substrate conveying system is smooth, etc. Make sure all parts are in good working order.

2) Glue preparation

According to production needs, operators need to rationally prepare the formula of water-based composite glue to ensure that the viscosity, viscosity and other properties of the glue meet the requirements. At the same time, regularly check the storage conditions of the glue to prevent agglomeration, deterioration and other phenomena.

3) Coating operation

After starting the water-based composite adhesive coating machine, the operator needs to set the coating parameters according to the product requirements, including coating amount, speed, temperature, etc. When performing coating operations, it is necessary to ensure that the substrate is transported evenly and that appropriate tension is maintained to avoid uneven coating or ripples.

4) Monitor and adjust

During the entire coating process, operators need to monitor parameters such as coating amount, glue temperature, and substrate tension at all times. Once an abnormality is discovered, the working parameters of the coating machine need to be adjusted in time to ensure the quality of the composite material.

3. Precautions for operating the water-based composite adhesive coating machine

safe operation

When using the water-based composite adhesive coating machine, operators must follow relevant safety operating procedures and wear protective equipment to avoid accidents. Coating machine equipment should be inspected regularly to ensure the effectiveness of all safety devices.

Glue storage and handling

Water-based composite glue needs to be protected from direct sunlight, high temperature, low temperature and other adverse conditions during storage and handling. Glue containers should be sealed and stored to prevent volatilization, agglomeration, etc. Waste glue should be disposed of in accordance with environmental protection regulations.

Equipment maintenance

Regular maintenance of the water-based composite adhesive coating machine is the key to ensuring long-term stable operation of the equipment. Including cleaning the coating roller, checking the surface wear of the coating roller, lubrication of various parts of the coating machine, etc.

Regular training of operators

The operation of the water-based composite adhesive coating machine requires professionally trained personnel to ensure that the operators understand the structure and working principle of the equipment and have correct operating skills. Training should also include emergency handling methods to improve the emergency response capabilities of operators.

environmental protection

During the production process, the water-based composite glue coating machine should comply with environmental protection requirements. Waste generated from waste water, waste glue, etc. needs to be processed in accordance with relevant regulations to ensure the environmental sustainability of the production process.

in conclusion

As an important industrial equipment, water-based composite glue coating machine is widely used in different industries. Understanding its technical principles, correct operating procedures and precautions is crucial to ensuring production quality and improving production efficiency. Operators should have professional training, have rich experience, and operate in strict accordance with safety regulations to ensure long-term stable operation of the equipment, while also paying attention to environmental protection and promoting sustainable development. The application of water-based composite glue coating machines will continue to develop in the future, and with the continuous innovation of technology, its performance and application fields will be further expanded.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative