Water-based Adhesive Spreader Equipment: Technical Principle, Type and Application Analysis

introduction

As an environmentally friendly and efficient coating method, water-based glue coating technology has been widely used in recent years. Water-based glue coating equipment is a key component of this technical system, and its performance and characteristics directly affect the coating effect and production efficiency. This article will deeply explore the technical principles of water-based adhesive coating equipment, the characteristics of different types of equipment, and its application in different application fields.

1. Principle of water-based adhesive coating technology

Water-based glue coating technology is a coating method based on water-based glue coating. Its principle mainly involves coating equipment, coating formula and process parameters, etc.

Coating equipment:

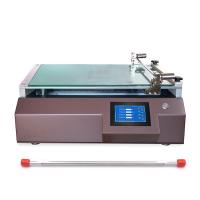

Water-based glue coating equipment usually includes coating machines, drying equipment, auxiliary equipment, etc. The coating machine applies the water-based glue on the surface of the substrate through rollers or spraying, while the drying equipment quickly dries the applied water-based glue through hot air or ultraviolet light to form a uniform coating film. Auxiliary equipment includes tension control, coating speed control, etc., to ensure the stability of coating.

Paint formula:

Water-based glue coating is a formula composed of water-based glue, additives, solvents, etc. Water-based glue is the core of this technology, and it has the functions of bonding and curing during the coating process. Auxiliaries include thickeners, dispersants, antibacterial agents, etc., used to improve the performance of coatings. Compared with solvent-based coatings, water-based glue coatings are more environmentally friendly and suitable for more fields.

Process parameters:

Water-based adhesive coating process parameters include coating speed, temperature, humidity, etc. Reasonable control of these parameters is crucial to ensuring coating quality. The choice of coating speed should consider factors such as the performance of the coating equipment and the drying speed of the coating. The control of temperature and humidity directly affects the curing speed of the water-based adhesive and the uniformity of coating.

2. Types of water-based glue coating equipment

Water-based glue coating equipment can be divided into various types according to different coating methods and application fields, including roller coating, spray coating and composite coating.

Roller coating equipment:

Roller coating equipment is a way to apply water-based glue on the surface of the substrate through a roller. This type of equipment usually includes coating rollers, tension control systems, etc. Because roller coating equipment is simple to operate and easy to control, it has been widely used in fields such as flexible packaging and label printing. However, roller coating equipment has certain limitations in terms of high precision and large area coating.

Spray coating equipment:

Spray coating equipment uses nozzles to spray water-based glue onto the substrate to form a uniform coating. This coating method is suitable for scenes with higher requirements such as coating thin films and fine patterns. Spray coating equipment usually has a high degree of automation and can adapt to different substrates and coating requirements. In the fields of electronics, photovoltaics and other fields, spray coating equipment has been widely used.

Composite coating equipment:

Composite coating equipment combines the advantages of roller coating and spray coating, providing greater flexibility. This type of equipment can switch in multiple ways during the coating process to adapt to different production needs. Composite coating equipment has been widely used in automobiles, building materials and other fields, especially in scenarios that require multi-layer composite coating, its advantages are more obvious.

3. Comparison of different types of water-based adhesive coating equipment

Accuracy and Uniformity:

Due to the limitations of its coating method, roller coating equipment may have certain limitations in some fields that require high coating accuracy and uniformity. In contrast, spray coating equipment and composite coating equipment can better meet the needs of high-precision coating.

Scope of application:

Roller coating equipment is widely used in fields such as flexible packaging and label printing. However, in some special fields such as electronics and photovoltaics that require high-precision coating, spray coating equipment and composite coating equipment are widely used. Cloth equipment has more advantages.

degree of automation:

Spray coating equipment and composite coating equipment usually have a high degree of automation and can realize intelligent control of the coating process. Roller coating equipment is relatively simple in this regard and requires more manual operations.

Productivity:

Composite coating equipment can better adapt to different production needs and improve production efficiency due to its combination of multiple coating methods. In some production lines that require multi-layer composite coating, composite coating equipment performs well.

4. Application of water-based adhesive coating equipment in different fields

Packaging industry:

Water-based glue coating equipment has been widely used in the packaging industry, especially in the field of flexible packaging. Roller coating equipment is common in this field. It is simple to operate and relatively low cost. It is suitable for large-area, high-volume packaging production lines. However, in some flexible packaging fields that require higher printing accuracy, spray coating equipment and composite coating equipment are more popular.

it:

In the electronics industry, especially in the fields of semiconductor manufacturing and electronic component manufacturing, spray coating equipment is widely used. Due to its high precision and high automation characteristics, spray coating equipment can meet the stringent requirements for coating accuracy of microelectronic devices. The application of water-based adhesive coating technology in the electronics industry is expected to be further expanded.

Building materials field:

In the field of building materials, composite coating equipment is often used to coat waterproof membranes, anti-corrosion membranes and other coatings. The combination of multiple coating methods makes the coating effect more uniform and more durable. The application of water-based glue coating technology in the field of building materials can help improve the environmental protection and durability of materials.

in conclusion

As an environmentally friendly and efficient coating method, water-based glue coating technology is increasingly used in different fields. Coating equipment is a key component of this technology, and its type and performance are directly related to the coating effect and production efficiency. When selecting water-based glue coating equipment, it is necessary to comprehensively consider the advantages and disadvantages of different types of equipment based on actual production needs and coating requirements in order to achieve better coating results. In the future, with the continuous development of water-based adhesive coating technology, it is believed that its application in more fields will be further promoted and deepened.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative