Encasement container sealing performance test method

Plastic packaging containers play an indispensable role in modern logistics, storage and transportation, and their sealing performance is one of the important indicators to ensure product quality and safety. This article will focus on testing methods for sealing performance of plastic packaging containers and its importance in protecting products. The sealing performance of plastic packaging containers evaluates their penetration and leakage of gases, vapors and liquids. During the packaging process, if the sealing performance of the container is not up to standard, the internal product may become damp, corrupt or leak, thus affecting the quality and safety of the product. Therefore, accurate and reliable testing of the sealing performance of plastic packaging containers is of vital significance.

Penetration and leakage

In sealing performance testing, penetration and leakage are two important concepts. Permeation refers to the process of diffusion of gas or vapor from an area of ââhigh concentration to an area of ââlow concentration through the walls of packaging materials. Leakage refers to the process of gas or vapor passing through a limited discontinuity in a material or packaging container. These discontinuities may be pinholes in the plastic film, the edges or cracks of the bottle, or even tiny rips between the cap and neck.

Sealing performance test method

In order to evaluate the sealing performance of plastic packaging containers, two methods, the vacuum test method and the weight change method, are usually used. The vacuum test method is suitable for packaging bags with a large air content. It is tested by observing whether the sample bag leaks in a vacuum environment. The weight change law uses the weight change of the liquid in the packaging bag or container to detect leakage, and obtains the penetration rate of the sample in a steady state by measuring the relationship between weight and time.

Plastic packaging container sealing performance test

For different types of plastic packaging containers, the sealing performance testing methods are also different. For plastic bottles, you can simply pour water into the sample bottle, then turn it upside down for a while and watch for leaks. For plastic buckets, you need to pour water into the bucket and perform a tilt and roll test under specific conditions to check for leaks. For dangerous goods packaging barrels, more stringent testing is required, including inflating or injecting water into the sample barrel and observing whether there is leakage under certain conditions.

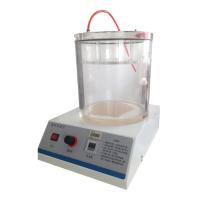

Commercial sealing performance testing instrument

In the market, there are many instruments and equipment specially used to test the sealing performance of plastic packaging containers. For example, the LSSD-01 leakage and sealing strength Tester produced by Jinan Languang Mechanical and Electrical Technology Co., Ltd., and the MFY-01 Sealing Tester can test the sealing performance of plastic packaging containers by applying pressure or vacuum testing.

Sealing performance is one of the key factors for plastic packaging containers to protect product quality and safety. Through accurate and reliable sealing performance testing, leakage problems of packaging containers can be discovered and solved in time, ensuring that products are not contaminated or damaged during transportation and storage. Therefore, strengthening the research and application of sealing performance testing methods for plastic packaging containers is of great significance to improving product packaging quality and protecting consumer rights.

-

-

-

-

-

-

-

CHINA ZY-MF Sealing Tester$ 679.00

-

-

Jinan HORIZON MFY-01 Sealing Tester$ 826.00