Determination of film Gloss by HNNJIK Instrument

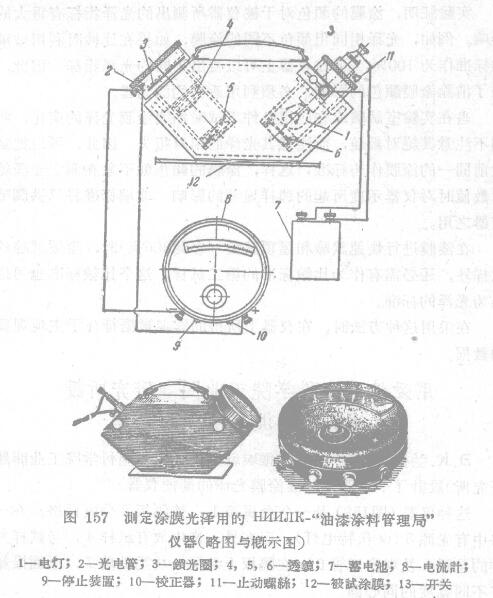

In 1938, HNNJIK worked out a photoelectric measurement method for paint film gloss and designed a special envoy for this purpose. The practicality of this method is that the light beam reflected from the tested paint sample passes through a set of lenses and gathers on the photosensitive layer of the photocell, resulting in the excitation of the photocurrent recorded by the pointer galvanometer. In 1940, the Leningrad branch of the "Paint Administration" changed the structure of the envoy to produce a portable instrument. See 157 for sketches and schematics of this instrument.

The components of this instrument include a light source 1 (25 volt electric lamp); a sensitivity of 350-450 microamperes/lumen; a photoelectric tube 2; a graduated locking aperture 3 (for adjusting the luminous flux on the phototube), and a set of lenses 4, 5 and 6. Electric lamp is powered by accumulator 7 (voltage 12 volts), or is passed to electric lamp terminal button by machine circuit under the condition of constant voltage through transformer and supplies power. (Related instrument: gloss meter)

The light stream from the lamp passes through the lens 6 and hits the test object. The light reflected from the surface is incident on the photosensitive layer of the phototube through a set of lenses 4 and 5, and the result is to excite the photocurrent recorded by the galvanometer. This instrument should be stored in a dry place at room temperature.

First start the device for 4 minutes and check whether the operation is in good condition according to the sketch (Fig. 157). Then move the instrument on a standard glass surface, turn the stop device 9 to the left to release the pointer of the ammeter 8, and adjust the pointer to zero by the calibrator 10. Then uncover the aperture by 20 mm on the graduation of the scale meter, connect the light source and calibrate the indicator of the galvanometer pointer, which should be equal to 100 (±2) degrees of the scale meter. When the galvanometer shows high or low, loosen the stop screw 11; move the concave socket of the light bulb to adjust the galvanometer pointer to 100 degrees of the scale meter (with an accuracy of ±2 degrees). Then stop: move the screw and tighten it again.

Put the adjusted instrument on the tested surface 12 and read the corresponding scale on the pointer of the galvanometer. The resulting value represents the gloss of the sample surface, and this value is expressed as a percentage of the gloss of the standard plate, and its accuracy is ±2 degrees from the scale of the galvanometer.

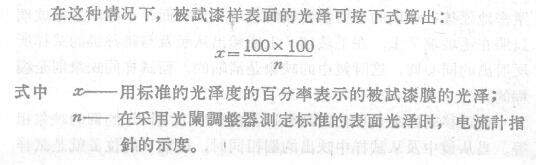

If the surface to be tested is superior in gloss to the surface of the standard plate, that is, if the pointer of the galvanometer is higher than 100 on the scale, adjust the pointer of the galvanometer to 100 (±2) by adjusting the diaphragm. Then move the instrument to the standard, and at the same time adjust the aperture, you can read the corresponding scale of the galvanometer pointer. (Related instrument: gloss meter)

Experiments have proved that the color of the coating film has a significant impact on the light-floating index measured by the dry quilt. For example, for coating films with the same gloss but different colors, if the glass standard is used as 100% in comparison, different gloss indicators can be obtained on the instrument. Therefore, in order to eliminate the influence of the color of the coating film, it is necessary to use an appropriate filter.

When testing changes in the gloss of a paint film in a laboratory test or under application conditions, we do not pay attention to its absolute value, but to its relative loss of gloss. Therefore, the same coating film before the test can be used as a standard; in this way, the color of the coating film does not have as significant influence on the instrument display as when measuring the absolute value of gloss. Glass standards will be used for instrument adjustment only.

In the quick test and roof test of the paint film, in addition to the tested sample, there must be a second sample as a comparison standard. This comparison standard can also be used as a gloss standard.

When using this method, the objective data obtained on the instrument are consistent with the subjective observation data.

- 1The Importance and Method of Gloss Measurement of Paint Film

- 2Film Gloss measurement and influencing factors

郑顺兴 - 《涂料与涂装科学技术基础》

- 3Coating film formation performance inspection method - film Color and Gloss

- 4Summary of film fog detection

- 5Gloss measurement of films with a Tester

- 6Determination of Film Gloss (glossiness)

- 7Common varieties of instrument painting Corresponding uses and characteristics

- 8How is Film Gloss Measured?

- 9How is film Gloss determined?