Analysis and application of self-adhesive laboratory coater technology

Self-adhesive coating technology is widely used in various application fields. In order to better study and apply self-adhesive adhesives, laboratory coaters have become a key tool. This article will deeply explore the technical characteristics, working principles, advantages and applications of self-adhesive laboratory coating machines in different fields. By analyzing the structure and function of the coating machine in detail, readers will have a more comprehensive understanding of the core of self-adhesive coating technology.

introduction

Self-adhesive adhesive is a special adhesive with excellent adhesion properties and convenient application characteristics, making it widely used in packaging, printing, medical, electronics and other industries. In order to better study and utilize self-adhesive adhesives, laboratory coaters have become indispensable equipment in laboratory research. This article will provide a detailed technical analysis around the self-adhesive laboratory coating machine, with a view to providing reference for related research and applications.

1. Technical features

1.1 Structural design

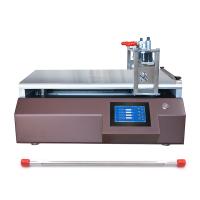

The structural design of the self-adhesive laboratory coating machine is the basis for its superior performance. Generally speaking, the machine mainly includes a base, coating roller, coating module, control system and other parts. The base provides stable support for the machine, and the coating roller is a key component of coating. Its surface is usually treated with a special process to ensure that the self-adhesive adheres evenly and stably to the substrate.

1.2 Coating module

The coating module is the core component of the self-adhesive laboratory coating machine, and its design directly affects the quality and efficiency of coating. Common coating modules include blade coating, roller coating, spray coating, etc. Different coating modules are suitable for self-adhesive adhesives with different viscosities and characteristics.

1.3 Control system

Modern self-adhesive laboratory coating machines are usually equipped with advanced control systems to achieve automation and precise control of the coating process. By monitoring coating parameters in real time, such as coating speed, pressure, temperature, etc., the control system can adjust the working status of the coating machine to meet different experimental needs.

2. Working principle

The working principle of the self-adhesive laboratory coating machine can basically be divided into the following steps:

2.1 Self-adhesive supply

First, the self-adhesive glue is fed into the coating machine's supply system. This typically includes the coater's tank, pump, and delivery piping. With these systems, the self-adhesive adhesive can be delivered precisely to the coating module.

2.2 Coating process

Under the action of the coating module, the self-adhesive glue is evenly coated on the substrate. Different coating modules have different principles. Blade coating uses a scraper to evenly scrape the glue onto the substrate, while roller coating achieves coating through the rotation of the roller.

2.3 Drying treatment

The coated substrate enters the drying stage to ensure that the self-adhesive adhesive can be cured quickly and improve adhesion and stability. Drying is usually achieved through a heating system, and a control system can adjust the temperature and time as needed.

2.4 Collection and analysis

After coating is completed, the substrate is removed through a collection system for subsequent analysis. Analysis can include parameters such as coating thickness, uniformity, etc. to evaluate the quality of experimental results.

3. Advantages and Applications

3.1 Advantages

Self-adhesive laboratory coaters have many advantages, making them widely used in scientific research and production. These mainly include:

Precise control: The advanced control system enables high-precision control of coating parameters, ensuring the repeatability and reliability of experiments.

Multiple coating modules: Flexible switching of different coating modules enables experimenters to choose the appropriate coating method according to experimental requirements.

High efficiency: The automated coating process and fast drying system improve the experimental efficiency and shorten the experimental cycle.

3.2 Application areas

Self-adhesive laboratory coaters are widely used in many fields, including but not limited to:

Electronics industry: Adhesives used to prepare electronic components, such as conductive adhesives.

Medical field: used in the production of medical patches, medical dressings, etc.

Packaging industry: Used to prepare various packaging materials to improve the sealing and adhesion of packaging.

Research Laboratory: Provides a platform for scientific researchers to explore the properties of new self-adhesive adhesives.

in conclusion

As a key experimental equipment, the self-adhesive laboratory coater provides important support for the research and application of self-adhesive adhesives. By in-depth understanding of its technical characteristics, working principles, advantages and application areas, we can better understand and utilize this technology. In the future, with the continuous development of science and technology, self-adhesive laboratory coating machines will continue to evolve, bringing more innovations and possibilities to various industries.

- 1Application of laboratory coater in LED fluorescent film Spreader

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Application of doctor blade coater in electrode and solid electrolysis preparation

- 4Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 5Experimental application of water-based paints on film laminating paper by laboratory coater

- 6Experimental coater application case video of liquid silica gel on release paper

- 7Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 8Application of small coater in gel coating

- 9Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane