Mayer-Rod (Mayer Rods) Preparative 2D Copper Nanosheets

Mayer-Rod, also known as mayer-rod, is a tool commonly used for film coating, especially for liquid materials with higher viscosity. When preparing two-dimensional copper nanosheets (Cu NPLs), Mayer-Rod can effectively achieve large-scale coating with excellent coverage and uniformity. The following is a detailed introduction to the process of preparing Cu NPLs using Mayer-Rod:

Materials and Equipment

Two-dimensional copper nanoplatelets (Cu NPLs) solution

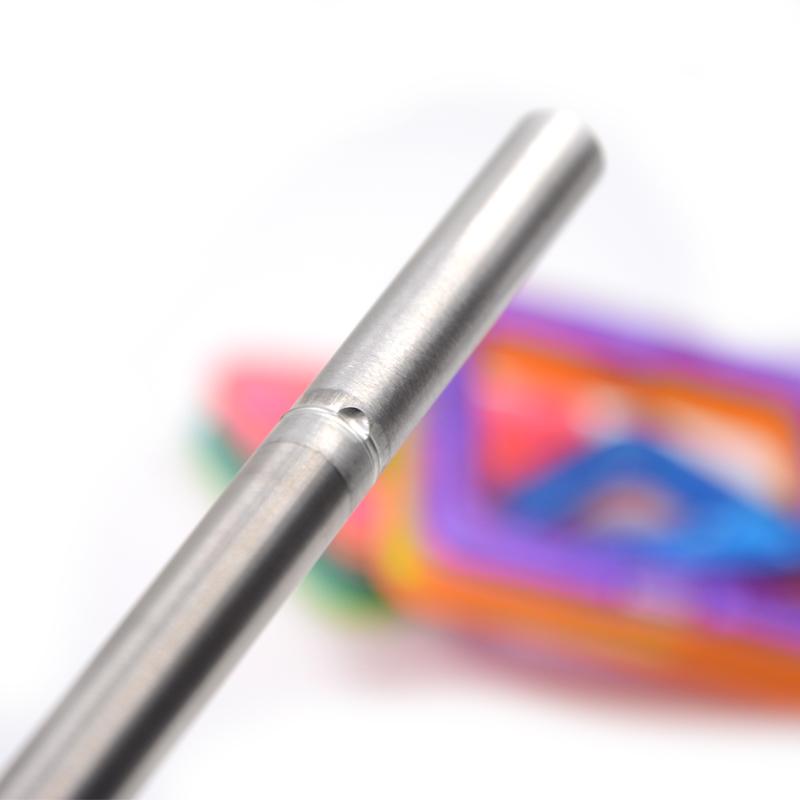

Mayer-Rod (mayer-rod)

Surface Tensiometer

quantitative glass slide

Laboratory Hot Plate

Pure nitrogen (N2) gas source

adjustable power supply

Preparation steps

Step 1: Prepare Cu NPLs solution

First, prepare a solution of two-dimensional copper nanoplatelets (Cu NPLs). The preparation method of Cu NPLs can refer to previous experimental literature, which is usually synthesized by reacting copper salts and surfactants under appropriate conditions, and using an appropriate solvent to disperse them into a solution.

Step 2: Adjust liquid viscosity

Use a Surface Tensiometer to measure the surface tension of the Cu NPLs solution. According to the coating requirements, the viscosity of the solution is adjusted, usually by adding an appropriate amount of solvent or adjusting the concentration of the solution.

Step Three: Prepare for Mayer-Rod

Preheat the Mayer-Rod on a laboratory Hot Plate to ensure that its surface temperature is suitable for the coating process. At the same time, an inert atmosphere around Mayer-Rod is maintained through a pure nitrogen (N2) gas source to prevent oxidation reactions from occurring.

Step 4: Coating process

Pour the adjusted viscosity Cu NPLs solution into the Mayer-Rod reservoir. Move the Mayer-Rod along the surface of the quantitative glass slide so that the solution is evenly coated on the surface of the glass slide. By adjusting the bevel angle and coating speed of the Mayer-Rod, the thickness and uniformity of the coating can be controlled.

Step 5: Drying and sintering

After the coating is completed, the glass piece is placed on a laboratory Hot Plate to dry to remove residual solvent. Then, the Cu NPLs can be rapidly sintered using intense pulsed light (IPL) sintering technology to obtain better conductivity and stability.

Step 6: Apply

The prepared Cu NPLs films can be used in various fields, such as electronic ink, electrochemical sensors, optoelectronic devices, etc. Prior to application, the film can be further characterized and performance tested to ensure it meets the requirements of the specific application.

Mayer-Rod is an effective tool that enables large-scale coating of Cu NPLs with excellent coating uniformity and coverage. By controlling the viscosity and coating parameters of the solution, the properties of Cu NPLs films can be precisely controlled during the preparation process, providing feasibility for their use in various applications.

- 1Application of Mayer Rods in protective coating prepative

- 2Application of Mayer Rods in 2D Single Crystal Copper Nanosheet Films

- 3Application of Mayer Rods in composite coating prepative

- 4Several Common Experimental Spreader Methods and Their Applications

- 5Application of Mayer Rods in Water-based ink Moulding

- 6Technical method and application of preparing nanometer silver wire thin films with Mayer Rods

- 7The experimental case of OSP Mayer Rods at inks Moulding [with video]

- 8Why Do Film Applicators Need to Change Their Wires Regularly?

- 9The overlooked role of Mayer Rods in laboratory wet-film preparation