Operation and maintenance method of sticker coater

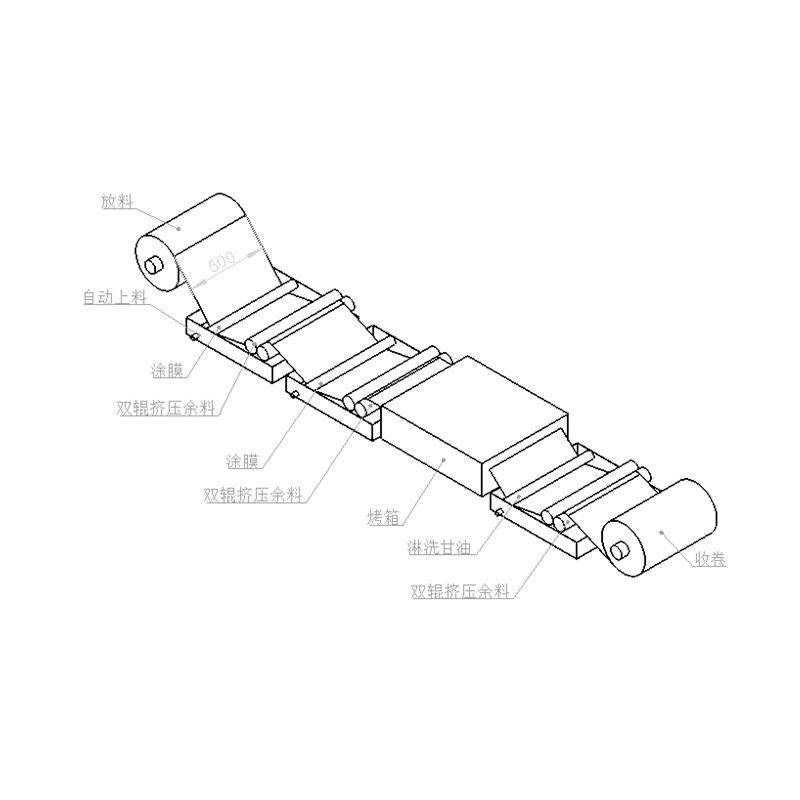

As an important piece of equipment on the production line, the self-adhesive coating machine's operation method is directly related to production efficiency and product quality. This article will introduce the operating procedures, adjustment techniques, troubleshooting and other aspects of the self-adhesive coating machine in detail to help practitioners better master the use skills of the self-adhesive coating machine.

Operating procedures

1. Preparation

Before operating the self-adhesive coating machine, adequate preparations are required. Check whether all parts of the equipment are firmly installed, check the quality of coating materials and bottom paper, and ensure that the coating machine is in normal working condition.

2. Adjust coating machine parameters

According to actual production needs, adjusting the parameters of the self-adhesive coating machine is a key operating step. Including the settings of coating speed, coating width, tension control and other parameters to ensure stability and accuracy during the coating process.

3. Installation of coating materials

Load the self-adhesive material onto the roll of the coating machine and smoothly transport it to the coating area through the guidance system. During this process, attention should be paid to the tension control of the material to ensure that no stretching or relaxation occurs during the coating process.

4. Start the coating machine

After starting the self-adhesive coating machine, pay close attention to the operating status of the equipment. By observing the coating uniformity of coating materials and the stability of coating speed, parameters can be adjusted in a timely manner to maintain good production status.

Adjustment skills

1. Coating pressure adjustment

The adjustment of coating pressure directly affects the adhesion and uniformity of coating materials. According to different material characteristics, the pressure of the coating roller should be reasonably adjusted to ensure that the coating pressure is moderate and avoid being too high or too low, resulting in poor coating results.

2. Temperature control

Coater temperature control is critical to drying and curing coating materials. According to the characteristics of the coating material, the temperature of the drying system is reasonably set to ensure that the coated material can be cured quickly and improve production efficiency.

3. Tension adjustment

During the coating process, the tension between the coating material and the backing paper must maintain a certain balance to prevent the coating material from stretching or relaxing. By adjusting the tension control system, the stable tension of the material during the coating process is maintained to ensure the coating effect.

Troubleshooting

1. Uneven coating

If uneven coating is found, first check whether the coating roller is clean and whether there are foreign objects. Adjust the coating pressure to ensure proper contact between the coating roller and the printing roller.

2. Tension problem

Tension problems during the coating process may cause the coating material to stretch or relax, affecting the coating effect. Check the tension adjustment system in time to ensure the balance of tension.

3. Equipment is blocked

Equipment clogging is one of the common failures of coating machines. Clean the coating roller, guide system and other parts of the coating machine in time to prevent production interruption due to blockage by foreign matter.

4. Equipment noise

Excessive equipment noise may be a symptom of equipment failure. Check whether the transmission parts of the equipment are well lubricated and replace worn parts in time to maintain normal operation of the equipment.

Regular maintenance

In order to ensure the long-term stable operation of the self-adhesive coating machine, regular maintenance is crucial. Including cleaning the inside of the equipment, replacing wearing parts, checking the wear of the coating roller, etc. Regular maintenance can improve the life and stability of the equipment.

The operation method of the self-adhesive coating machine is directly related to production efficiency and product quality. Through adequate preparation, fine parameter adjustment, flexible installation of coating materials, and timely troubleshooting, the normal operation and efficient production of the self-adhesive coating machine can be ensured. Regular maintenance work is the key to ensuring long-term stable operation of equipment. Operators should have rich operating experience and in-depth understanding of the equipment to ensure that the coating machine reaches good working condition during the production process.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative