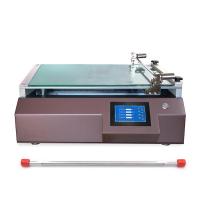

Continuous hot-melt adhesive Automatic Film Applicator film accuracy improvement practice

Continuous hot melt adhesive coating testing machines are widely used in various fields in modern industry, such as packaging, sanitary product manufacturing, and electronic equipment production. In order to meet the high requirements for coating film accuracy in different industries, it is crucial to continuously improve the performance and accuracy of coating testing machines. This article will explore some technical means and methods to improve the coating accuracy of the continuous hot melt adhesive coating testing machine.

introduce

1.1 Background of continuous hot melt adhesive coating testing machine

Before introducing the technical improvements, let us first understand the basic principles and application fields of the continuous hot melt adhesive coating testing machine. The continuous hot melt adhesive coating testing machine is a device that realizes continuous production through hot melt adhesive coating technology. It is widely used in bonding, packaging, coating and other processes. Its working principle is to heat the solid hot melt adhesive to a liquid state, and then evenly apply it on the substrate through the coating head to finally form a coating film.

1.2 The importance of coating accuracy to product quality

The coating accuracy is directly related to the quality and performance of the product. In various industries, the requirements for product appearance, durability, optical properties, etc. are getting higher and higher. Therefore, coating testing machines are required to have higher coating accuracy to meet market demand.

Technical Improvement

2.1 Coating head design optimization

2.1.1 Fluid dynamics analysis

Through fluid dynamics analysis of the coating head, its internal structure can be optimized so that the hot melt adhesive can flow more evenly and maintain stable pressure during the coating process. This helps reduce the coating thickness difference between the coating head and the substrate and improves the uniformity of the coating film.

2.1.2 Material selection and surface treatment

Material selection and surface treatment of the applicator head are critical to reducing friction, preventing adhesive residue, and reducing static effects. The use of reliable materials and surface treatment technologies, such as ceramic coatings or special coatings, can effectively reduce friction and improve the wear resistance and service life of the coating head.

2.2 Temperature control system upgrade

2.2.1 Improvement of hot melt adhesive temperature accuracy

By using more sophisticated temperature sensors and control systems, more precise control of the temperature of hot melt adhesive can be achieved. This helps avoid uneven coating thickness problems caused by temperature fluctuations and improves film consistency.

2.2.2 Improvement of uniformity of heating system

Optimize the design of the heating system to ensure that heat can be transferred evenly to the coating head and prevent local temperatures from being too high or too low. By using reliable temperature sensors such as thermocouples and thermistors, the temperature distribution can be monitored in real time and the heating system can be adjusted in a timely manner to improve the temperature uniformity of the entire coating process.

2.3 Control system upgrade

2.3.1 Application of high-precision control algorithm

Using a high-precision control algorithm, the movement speed and position of the coating head can be adjusted more accurately, thereby achieving more precise coating thickness control. This algorithm usually combines sensor feedback and closed-loop control to quickly respond to changes and ensure stability during the coating process.

2.3.2 Intelligent monitoring and adjustment

An intelligent monitoring system is introduced to monitor various parameters in the coating process in real time through data collection and analysis, and automatically adjust the working status of the coating head according to the actual situation. This helps to detect and correct potential problems in a timely manner, improving production efficiency and coating accuracy.

Part Three: Experimental Verification and Result Analysis

After the above-mentioned technical improvements were made to the coating testing machine, a series of experimental verifications were conducted, including coating film thickness measurement, coating film uniformity analysis, etc. By comparing the data before and after the experiment, the effect of technical improvements on improving coating accuracy can be clearly evaluated.

Through technical improvements to the continuous hot-melt adhesive coating testing machine, we have achieved significant improvements in coating film accuracy. However, with the continuous advancement of science and technology, we still face many challenges, such as improving production efficiency and reducing energy consumption. In the future, we can further explore reliable materials science, automation technology and other fields to continuously promote the development of continuous hot melt adhesive coating testing machines and meet increasingly stringent industrial needs.

- 1Lab Film Applicator Application Case of applying water-based paints on paper [with experimental video]

- 2Experimental Application Technology of Resin Film Prepared by Spreader

- 3Application and advantage analysis of Lab Film Applicator in solder paste film

- 4Application Selection of Lab Film Applicator in Optical inspection of Transparent Film Preparative

- 5Research and Application of Waterproof Membrane Lab Film Applicator

- 6Analysis of Hot-melt adhesive Automatic Film Applicator Technology: Principle, Structure, Operation and Application

- 7Preparation of Conductive Films on Nonwoven Fabrics by Small Coating Testing Machine

- 8Instructions for use of Kimpt small automatic coating machine

- 9Application of Spreader Testing Machine in Paper Spreader Production