Review of lame plating hot-melt adhesive coater technology

introduction

With the rapid development of modern industry, the demand for efficient and precise coating technology in the manufacturing field is increasing. As a reliable coating technology, the spray hot melt adhesive coating machine has gradually become one of the indispensable equipment in the production lines of various industries due to its high efficiency, accuracy, environmental protection and other characteristics. This article will introduce in detail the working principle, technical characteristics, application fields and future development trends of the spray hot melt adhesive coating machine in order to better understand and apply this reliable coating technology.

1. Working principle

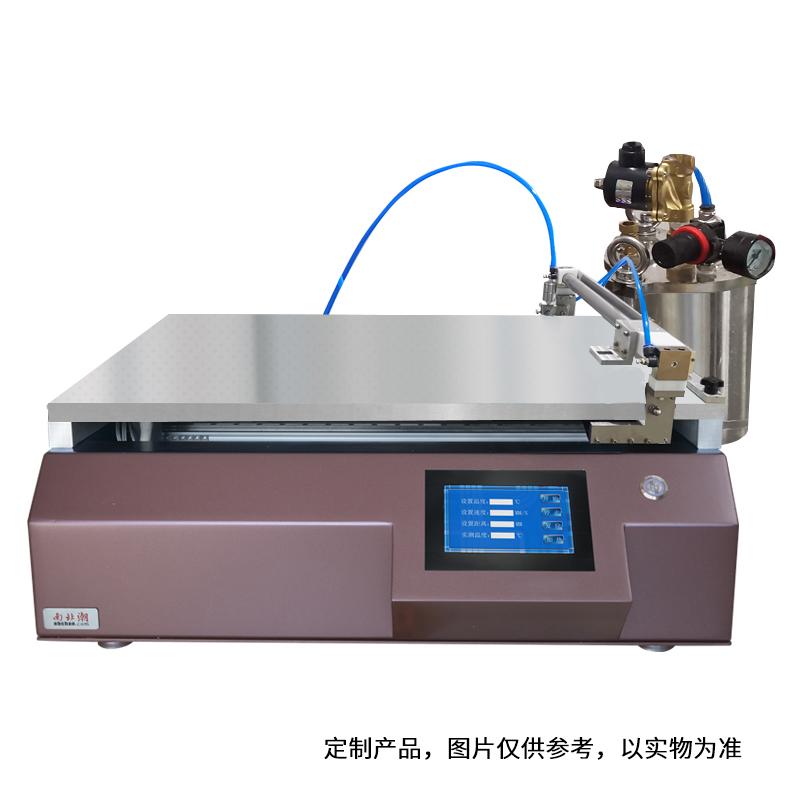

1.1 Overview of spray hot melt adhesive coating machine

The spray hot melt adhesive coater is a device that uses hot melt adhesive to evenly spray coating materials on the surface of the workpiece. Its working principle mainly includes heating system, coating system, conveying system and control system.

1.2 Heating system

The heating system is one of the core components of the spray hot melt adhesive coating machine. Electric heating or gas heating is usually used to heat the hot melt adhesive to its melting point to form a flowing melt pool. The stability and control accuracy of the heating system directly affect the coating effect and production efficiency.

1.3 Coating system

The coating system includes melt nozzles, nozzle control systems, coating rollers and other components. The melt is evenly sprayed on the surface of the workpiece through the nozzle, and the nozzle control system adjusts the spray amount and speed of the melt through precise control to adapt to the needs of different workpieces. The coating roller is used to flatten the melt evenly to ensure coating quality.

1.4 Conveyor system

The conveyor system is responsible for stably transporting the workpiece to be coated to the coating area and sending it out after the coating is completed. The design of the conveyor system needs to consider factors such as the shape, size and weight of the workpiece to ensure the stability and consistency of the coating process.

1.5 Control system

The control system is the brain of the entire spray hot melt adhesive coating machine. It monitors and adjusts the heating system, coating system and conveying system in real time through sensors, PLC and other equipment. A reliable control system can achieve precise control of coating parameters and improve coating quality and production efficiency.

2. Technical characteristics

2.1 Efficient coating

The spray hot melt adhesive coating machine has the characteristics of efficient coating. Due to the use of hot melt adhesive, the coating speed is faster, and the fluidity of the melt glue makes the coating more uniform. Compared with traditional coating methods, spray hot melt adhesive coating machines can complete the coating process in a shorter time and improve production efficiency.

2.2 Precise coating

The coating system adopts reliable control technology to achieve precise adjustment of coating parameters. The nozzle control system can adjust the spray volume and spray speed according to the shape and size of the workpiece to ensure coating consistency and accuracy. This makes spray hot melt adhesive coating machines widely used in fields that require high coating quality, such as electronics, automobiles, medical and other industries.

2.3 Energy saving and environmental protection

Compared with traditional coating methods, spray hot melt adhesive coating machines are more efficient in energy use. The heating system uses electric heating or gas heating, which can quickly heat the hot melt adhesive to the working temperature and reduce energy waste. Moreover, hot melt adhesive does not produce volatile organic compounds during the coating process, reducing environmental pollution and meeting the requirements of modern industry for energy conservation and environmental protection.

2.4 Multi-material adaptability

The spray hot melt adhesive coating machine can be adapted to a variety of coating materials, including different types of hot melt adhesives, tapes, films, etc. This multi-material adaptability makes the coating technology more flexible and able to meet the needs of different industries and processes.

2.5 High degree of automation

The reliability of the control system makes the spray hot melt adhesive coating machine highly automated. Through equipment such as PLC, automatic adjustment of coating parameters and real-time monitoring of the production process can be achieved. This not only reduces the difficulty of manual operation and improves production efficiency, but also reduces the impact of human factors on coating quality.

3. Application fields

3.1 Electronics industry

Spray hot melt adhesive coating machines are widely used in the electronics industry. In the manufacturing process of electronic products, circuit boards, components, etc. need to be sealed and fixed, and the spray hot melt adhesive coater can complete this task efficiently and accurately. Its precise coating characteristics ensure the quality and stability of electronic products.

3.2 Automobile manufacturing

In the automobile manufacturing process, coating is an indispensable link. The spray-type hot melt adhesive coating machine can be used for coating automobile interiors, sealing strips, waterproof membranes, etc. Its high efficiency and accuracy meet the requirements of automobile manufacturing for production efficiency and product quality.

3.3 Medical industry

In the medical industry, spray hot melt adhesive coating machines are widely used in the manufacturing process of medical devices. For example, the coating of medical tapes, medical packaging materials, etc. can be achieved through spray-type hot melt adhesive coating machines to ensure the hygienic safety of the products.

3.4 Packaging field

In the field of packaging, spray hot melt adhesive coating machines can be used for coating packaging materials, such as carton sealant, packaging film coating, etc. Its characteristics of efficient coating and precise coating improve the efficiency of packaging production lines and packaging quality.

3.5 Construction field

In the construction field, spray hot melt adhesive coating machines can be used for the production of building materials, such as the coating of insulation materials, waterproof materials, etc. Its efficient and precise coating characteristics meet the requirements for material performance and construction efficiency in the construction field.

in conclusion

As a reliable coating technology, spray hot melt adhesive coating machine has been widely used in various fields due to its high efficiency, accuracy and environmental protection. By in-depth understanding of its working principle, technical characteristics, application fields and future development trends, we can better grasp the advantages of this technology and apply it more flexibly in actual production. With the continuous advancement of technology, spray-type hot melt adhesive coating machines are expected to achieve greater breakthroughs in the future, providing more reliable and efficient coating solutions for manufacturing in various industries.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Application of doctor blade coater in electrode and solid electrolysis preparation

- 3Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 4Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 5Several Common Experimental Spreader Methods and Their Applications

- 6Application of laboratory coater coating aluminum oxide paste on PET film

- 7Experimental test of performance of epoxy resin film coated on metal iron plate by small coater

- 8Method and application of experimental coater coating water-based slurry on aluminum foil

- 9Application of wire rod coater in hydrogen battery separator prepative