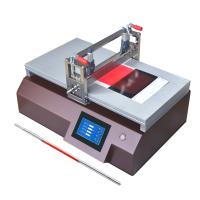

Working Principle and Application of PE Protective Film Coating Machine

With the continuous development of social science and technology, all walks of life have an increasing demand for efficient, environmentally friendly, and high-quality production. In the field of packaging, PE protective films are widely used on product surfaces to protect them from environmental factors such as scratches, dust, and moisture. As a key equipment on the production line, the PE protective film coating machine plays a vital role in the coating quality and efficiency of the protective film.

Working principle of PE protective film glue applicator

The PE protective film glue applicator mainly completes the coating process through the following steps:

1. Substrate loading

First, the base material of the PE protective film is loaded into the feeding system of the glue coating machine. This step requires the equipment to have an automatic feeding system to ensure efficient and accurate feeding of the substrate into the glue applicator.

2. Glue coating system

The glue coating system is the core part of the PE protective film glue coating machine. It includes a rubber coating roller, a rubber roller coating system on the surface of the rubber coating roller, and a coating roller. Through the coating roller, the adhesive is evenly coated on the surface of the PE protective film. The design and control of the coating roller is one of the important factors affecting coating quality.

3. Drying system

After the coating is completed, the PE protective film needs to be heated through a drying system to quickly solidify the adhesive and ensure the adhesion between the film and the substrate. An efficient drying system can not only improve production efficiency, but also reduce energy consumption.

4. Reeling system

The winding system of the PE protective film coating machine is used to roll the coated protective film into rolls to facilitate subsequent packaging and transportation. The design of the winding system needs to take into account the tension control of the film material to prevent problems caused by uneven tightness of the film material during the winding process.

Key technologies of PE protective film glue applicator

1. Coating roller design

The design of the coating roller directly affects the uniformity and quality of coating. The use of reliable coating roller designs, such as uniform rubber rollers, slightly convex coating rollers, etc., can ensure even distribution of adhesive on the film surface and improve coating quality.

2. Temperature control technology

Since different film materials and adhesives have different sensitivity to temperature, the temperature of the coating roller and drying system needs to be precisely controlled during the coating process. Reliable temperature control technology can ensure stable coating results under different working conditions.

3. Tension control

In the coiling system, precise tension control is the key to ensuring coiling quality. Using reliable tension sensors and control systems, real-time monitoring and adjustment of membrane tension can be achieved to ensure the tightness and flatness of the membrane during the rolling process.

4. Intelligent control system

The intelligent control system of the PE protective film coating machine covers functions such as setting of coating parameters, real-time monitoring of production data, and automatic diagnosis of equipment status. Through intelligent control, operators can more conveniently adjust coating parameters and improve production efficiency. At the same time, equipment failures can also be handled in a timely manner.

Advantages of PE protective film glue applicator in practical applications

1. Improvement of production efficiency

Using reliable coating technology and intelligent control systems, the PE protective film coating machine can achieve efficient and stable production during the coating process, greatly improving production efficiency.

2. Reduce energy consumption

Reliable drying systems and temperature control technology can effectively reduce energy consumption and reduce environmental impact. This is in line with society's demand for green production and the direction of sustainable development of enterprises.

3. Improve coating quality

Through precision coating roller design and reliable tension control technology, the PE protective film glue applicator can ensure the uniformity and stability of coating quality, making the coated film smoother, more transparent, and with good adhesion.

4. Wide applicability

The PE protective film glue applicator can be applied to different types of PE protective films and substrates, and has high versatility. This enables the equipment to be widely used in multiple industries, including electronic products, glass products, metal materials and other fields.

Development Trend of PE Protective Film Glue Coating Machine

1. Intelligence and automation

In the future, PE protective film glue applicators will become more intelligent and automated. Reliable sensor technology, machine learning algorithms and human-computer interaction interfaces will be widely used, making equipment easier to operate, automatically diagnosing faults, and improving the intelligence level of production lines.

2. Adaptability of new materials

With the continuous emergence of new materials, PE protective film glue applicators need to be more adaptable and can be applied to various new protective films and substrates. This will prompt the glue applicator to continue to innovate in coating technology and equipment structure.

3. Energy saving and environmental protection

In the future, PE protective film glue applicators will pay more attention to energy conservation and environmental protection, and adopt more efficient energy utilization methods to reduce the impact on the environment. Green production concepts will become an important consideration in equipment design and manufacturing.

4. Digital production management

With the rapid development of information technology, PE protective film glue applicators will pay more attention to digital production management. Through real-time monitoring and analysis of production data, we can better understand the operating status of equipment, improve production efficiency, and provide a more accurate reference for equipment maintenance.

in conclusion

As an important piece of equipment in the packaging industry, the PE protective film glue applicator has made significant progress in coating technology, intelligent control and production efficiency. With the continuous development of technology and changing market demands, glue applicators will continue to face new challenges and opportunities. Through continuous innovation to better adapt to various new materials and different production needs, it will make greater contributions to the sustainable development of the packaging industry.