Water-based Pressure sensitive adhesive coating machine selection technical guide

As a green and environmentally friendly coating material, water-based pressure-sensitive adhesive has gradually been widely used in various industries. As one of the key pieces of equipment, the water-based pressure-sensitive adhesive applicatorâs selection is crucial to production efficiency, coating quality, and environmental protection indicators. This article will provide detailed technical guidance for the selection of water-based pressure-sensitive adhesive applicators from the basic principles, key technical indicators, and selection points of the glue applicator.

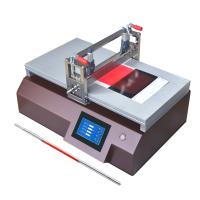

Basic principles of water-based pressure-sensitive adhesive applicator

The water-based pressure-sensitive adhesive coating machine is a special equipment. Its basic working principle includes base material feeding, glue coating system, drying system and coiling system. The following is the basic workflow of the water-based pressure-sensitive adhesive applicator:

1. Substrate feeding

First, the substrate to be glued needs to be fed into the feeding system of the glue coating machine. The substrate can be different types of materials such as paper and film, so the glue applicator needs to have corresponding feeding adaptability.

2. Glue coating system

The glue coating system is the core part of the water-based pressure-sensitive adhesive coating machine. It evenly coats the water-based pressure-sensitive glue on the surface of the substrate through a coating roller. This step requires equipment with a high-precision glue coating system to ensure that the glue is evenly and stably coated on the surface of the substrate.

3. Drying system

The drying system is used to quickly cure the water-based pressure-sensitive adhesive coated on the substrate to form an adhesive layer with strong adhesion and stability. An efficient drying system can improve production efficiency and reduce energy consumption.

4. Reeling system

After the glue coating is completed, the substrate needs to be rolled into a roll through a take-up system to facilitate subsequent packaging and transportation. The design of the winding system needs to take into account the tension control of the substrate to prevent problems caused by uneven tightness during the winding process.

Key technical indicators for selecting water-based pressure-sensitive adhesive applicators

1. Gluing width and speed

Gluing width and speed are one of the key technical indicators that need to be considered when selecting a glue coating machine. According to the production needs and substrate width, select a glue applicator of appropriate width and speed to ensure production efficiency and quality.

2. Coating uniformity

The coating uniformity of water-based pressure-sensitive adhesive is directly related to the quality of the product, so the coating uniformity is an important consideration when selecting. Choosing a glue applicator with a high-precision glue application system and coating roller design can ensure uniform and stable glue application.

3. Drying system effect

The effect of the drying system directly affects the curing speed and quality of the glue. When selecting, factors such as the heating method and temperature control accuracy of the drying system need to be considered to ensure that the water-based pressure-sensitive adhesive can solidify quickly during the drying process and achieve better adhesion.

4. Tension control

During the coating and coiling process, the tension of the substrate needs to be effectively controlled. Choosing a glue applicator with a high-precision tension control system can prevent the problem of uneven tightness of the substrate during the coating and coiling process and ensure the flatness of the product.

5. Degree of automation

With the development of intelligent manufacturing, the degree of automation of the glue applicator has also become a factor that needs to be considered when selecting a model. Automatic feeding, automatic adjustment of coating parameters, automatic fault diagnosis and other functions can improve the intelligence level of the production line and reduce the difficulty of operation.

Key points and precautions for selecting a water-based pressure-sensitive adhesive applicator

1. Production demand analysis

Before selecting, you need to fully understand the production needs, including product specifications, coating speed, production line width, etc. A thorough understanding of your production needs will help you select the appropriate glue applicator model.

2. Consider substrate type

Water-based pressure-sensitive adhesive applicator is suitable for different types of substrates, including paper, film, etc. Select the suitability of the glue applicator according to different base materials to ensure that the equipment can operate stably.

3. Pay attention to energy consumption and environmental protection indicators

With the popularization of environmental protection concepts, it is necessary to pay attention to the energy consumption and environmental protection indicators of the glue applicator when selecting a model. Choosing a glue applicator with higher energy efficiency and lower waste emissions can help companies achieve green production.

4. Brand reputation and after-sales service

Choosing a manufacturer with good brand reputation and perfect after-sales service can ensure the stability and long-term operation of the equipment. Brand reputation is a very critical consideration in selection.

5. Budget and return on investment

Budget and return on investment need to be considered when selecting. Although high-end equipment usually has more reliable features, choose a more cost-effective glue applicator based on actual needs to ensure a reasonable return on investment.

in conclusion

The selection of a water-based pressure-sensitive adhesive applicator involves many aspects of technical indicators and considerations. Enterprises need to make comprehensive considerations based on their own production needs, environmental protection concepts, budget and other factors when making specific choices. With the continuous advancement of science and technology, glue coating machines will continue to develop in the direction of intelligence, energy saving, environmental protection, and multi-functionality, providing enterprises with more efficient and green coating solutions.