Research and Application of Waterproof Membrane Lab Film Applicator

Waterproofing membranes play a vital role in construction projects, and coating is one of the key steps in their preparation. In order to ensure the quality and performance of waterproofing membranes, the coating process needs to be strictly controlled and tested. This article introduces the technical principles, structural design, application scope and future development direction of the waterproof membrane coating testing machine, aiming to provide technical support and reference for the production and research and development of waterproof membranes.

Waterproof membrane is a waterproof material widely used in construction projects. It has good waterproof performance and durability and can effectively protect buildings from water erosion. In the preparation process of waterproof membranes, coating is a crucial process step, which directly affects the quality and performance of waterproof membranes. In order to ensure the stability and controllability of the coating process, special testing equipment needs to be used to test and monitor it. The waterproof membrane coating testing machine is an important equipment used to evaluate the coating performance of waterproof membranes.

Technical principles

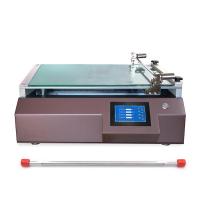

The main technical principle of the waterproof membrane coating testing machine is to evenly coat the coating glue on the surface of the substrate by controlling the movement trajectory and coating pressure of the coating head. Its working principle is similar to that of a conventional coating machine, but it is more precise in design and can achieve higher coating accuracy and stability.

Coating testing machines usually consist of coating heads, transmission systems, control systems and other parts. The coating head is a key component of the entire system, and its design directly affects the coating effect. The transmission system is used to control the movement trajectory and speed of the coating head and adjust the coating pressure. The control system is responsible for monitoring and adjusting the working status of the entire system to ensure the stability and controllability of the coating process.

structural design

The structural design of the waterproof membrane coating testing machine needs to take into account various factors in the coating process, such as coating speed, coating pressure, substrate surface treatment, etc. Generally speaking, the structural design of the coating testing machine should have the following characteristics:

Precision coating head design: The coating head is the core component of the entire system. Its design should take into account factors such as the viscosity of the coating compound and the surface properties of the substrate to ensure the uniformity and stability of the coating process.

Stable transmission system: The transmission system should be able to accurately control the movement trajectory and speed of the coating head, as well as adjust the coating pressure, so as to achieve precise control of the coating process.

Reliable control system: The control system should be able to monitor and adjust the working status of the entire system to ensure the stability and controllability of the coating process. At the same time, it should also have data collection and analysis functions to facilitate users to monitor and analyze the coating process.

Humanized operation interface: The operation interface should be simple and intuitive, making it convenient for users to operate and monitor. At the same time, it should also have alarm and fault diagnosis functions to detect and solve problems in time.

Key elements of film production

In the production process of waterproof membranes, coating is a crucial step, and its quality directly affects the performance and reliability of the final product. In order to ensure the stability and controllability of the coating process, the key elements of the waterproof membrane coating testing machine film play a vital role. The following are the key elements of waterproofing membrane coating testing machine:

1. Coating head design

The coating head is the core component of the waterproof membrane coating testing machine, and its design directly affects the uniformity and stability of coating. The coating head needs to have good sealing and wear resistance to ensure that the coating material is evenly coated on the surface of the substrate. In addition, the structural design of the coating head should also take into account the viscosity and fluidity of the coating material to achieve precise control of the coating process.

2. Transmission system

The transmission system is another key component of the waterproof membrane coating testing machine. Its main function is to control the movement trajectory and speed of the coating head and adjust the coating pressure. The transmission system needs to have stable movement performance and precise control capabilities to ensure the stability and controllability of the coating process.

3. Control system

The control system is the brain of the waterproof membrane coating testing machine. Its main function is to monitor and adjust the working status of the entire system to ensure the stability and controllability of the coating process. The control system needs to have a high level of automation and intelligence, and can realize real-time monitoring and adjustment of coating parameters to meet the requirements of different coating processes.

4. Substrate treatment system

The substrate treatment system is an important part of the waterproof membrane coating testing machine. Its main function is to pretreat the substrate to improve its surface adhesion and wettability. The substrate treatment system usually includes cleaning, primer coating and other process links, which need to be adjusted and optimized according to different substrates and coating processes.

5. Data collection and analysis system

The data acquisition and analysis system is the key support of the waterproof membrane coating testing machine. Its main function is to monitor and record key parameters in the coating process in real time, such as coating speed, coating pressure, coating thickness, etc. The data collection and analysis system can also perform statistical analysis and report generation on the collected data, providing a reference for the optimization of the coating process.

Application industry

The waterproof membrane coating testing machine plays a vital role in the coating process and is mainly used in the following industries:

In construction projects, waterproofing membranes are used for waterproofing treatment on roofs, basements, walls and other parts. The waterproof membrane coating testing machine is widely used to control and optimize the coating process of producing waterproof membranes to ensure the waterproof performance and durability of the building structure.

In road and bridge engineering, waterproofing membranes are used for waterproofing treatment of bridge panels, tunnel walls and other parts. The coating testing machine can be used to evaluate the coating performance of waterproof membranes to ensure their effectiveness in complex environments.

In the transportation industry, waterproof membranes are widely used in waterproofing treatments for subways, high-speed rails, ships and other means of transportation and facilities. The coating testing machine can help manufacturers accurately control the coating process of waterproof membranes to adapt to the needs of different transportation environments.

In the field of environmental engineering, waterproof membranes are used for waterproofing in environmentally sensitive areas such as landfills and sewage treatment plants. The coating testing machine can be used to evaluate the performance of waterproofing membranes under different environmental conditions to ensure its reliability and stability in environmental engineering.

In the energy industry, waterproof membranes are widely used in waterproofing treatment of energy facilities such as electricity, oil, and natural gas. The coating testing machine can help manufacturers optimize the coating process of waterproof membranes and improve its application efficiency and safety in the energy field.

in conclusion

The waterproof membrane coating testing machine is an important equipment in the production and research and development process of waterproof membranes and has wide application prospects and development space. Through continuous technological innovation and research and development, it will help improve the production efficiency and product quality of waterproof membranes and promote the development of the waterproof material industry. It is believed that with the continuous advancement of science and technology, waterproof membrane coating testing machines will play an increasingly important role in the future and make greater contributions to the development of construction projects.

- 1Lab Film Applicator Application Case of applying water-based paints on paper [with experimental video]

- 2Experimental Application Technology of Resin Film Prepared by Spreader

- 3Application and advantage analysis of Lab Film Applicator in solder paste film

- 4Application Selection of Lab Film Applicator in Optical inspection of Transparent Film Preparative

- 5Continuous hot-melt adhesive Automatic Film Applicator film accuracy improvement practice

- 6Analysis of Hot-melt adhesive Automatic Film Applicator Technology: Principle, Structure, Operation and Application

- 7Preparation of Conductive Films on Nonwoven Fabrics by Small Coating Testing Machine

- 8Instructions for use of Kimpt small automatic coating machine

- 9Application of Spreader Testing Machine in Paper Spreader Production