The preparatory application of laboratory coater in AR membrane

introduction

In today's era of rapid technological advancement, the development of optical technology has become an indispensable part in many fields. Among them, the application of anti-reflection (AR) technology is particularly prominent. Antireflection coating is a film that can reduce surface reflection of optical components and increase transmittance. It is widely used in optical equipment such as glasses, camera lenses, and displays. The application of laboratory coaters in antireflection films is to achieve precise control and efficient production of films. This article will discuss the application and significance of laboratory coaters in the preparation of antireflection films.

1. Overview of antireflection coating technology

The core goal of anti-reflection coating technology is to reduce reflection on the surface of optical devices and improve the transmittance of optical devices, thereby improving their performance. By depositing one or more layers of specific materials on the optical surface to form a thin film, the reflection of the surface can be effectively reduced. Anti-reflection coating technology has a wide range of applications, involving glasses, camera lenses, solar panels and other fields.

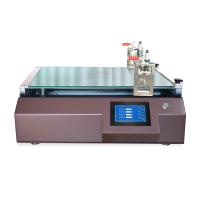

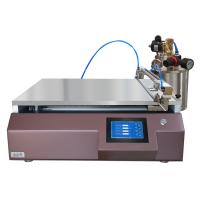

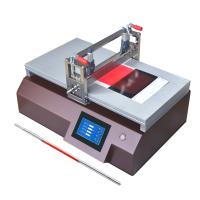

2. Introduction to laboratory coating machine technology

The laboratory coater is a device used for film preparation. It has a high-precision coating control system and multi-functional process parameter settings, which can achieve precise control of the film preparation process. Generally speaking, a laboratory coating machine includes a substrate processing unit, a coating unit, a drying unit and other components. Through the synergy of these units, uniform coating and efficient drying of thin film materials can be achieved, thereby obtaining a coating with certain properties. Thin film products.

3. Application of laboratory coater in preparation of antireflection coating

Precise coating control : The laboratory coating machine has a high-precision coating control system, which can achieve precise control of film thickness, composition, structure and other parameters. During the AR coating preparation process, this precise coating control can ensure that the resulting film has good optical properties, such as high transmittance and low reflectivity.

Multifunctional process parameter settings : The laboratory coating machine has multifunctional process parameter settings, which can flexibly adjust coating speed, drying temperature, substrate treatment method and other parameters to adapt to different materials and process requirements. In the preparation of anti-reflection coatings, this multi-functional process parameter setting can meet the requirements of different film materials and ensure that the obtained anti-reflection coatings have stable performance.

Efficient production capacity : The laboratory coater has efficient production capacity and can achieve rapid coating and drying of large-area substrates, thereby improving production efficiency. In the preparation of anti-reflection coatings, this efficient production capacity can meet the needs of large-scale production and provide technical support for the commercial application of anti-reflection coatings.

Develop new anti-reflection coating materials : The laboratory coater provides a good platform for the development of new anti-reflection coating materials. By adjusting coating process parameters, optimizing material formulas, etc., rapid screening and optimization of new antireflection coating materials can be achieved, providing technical support for the further development of antireflection coating technology.

4. The significance of laboratory coater in the preparation of antireflection coating

The application of laboratory coaters in the preparation of antireflection coatings is of great significance:

Improve production efficiency : The laboratory coating machine can achieve efficient control of the film preparation process, which can greatly improve the production efficiency of anti-reflection coating and reduce production costs.

Optimize product performance : The laboratory coating machine has a high-precision coating control system, which can ensure that the obtained anti-reflection coating has stable optical properties and improve product quality and reliability.

Promote the development of anti-reflection coating technology : The laboratory coating machine provides a good platform for the development of new anti-reflection coating materials, which can accelerate the development and commercialization of new materials and promote the development of anti-reflection coating technology.

Expand application fields : The laboratory coating machine can flexibly adjust process parameters to adapt to different materials and process requirements, and can expand the application fields of anti-reflection coatings to meet the needs of different fields.

in conclusion

Laboratory coaters have important application value and significance in the preparation of antireflection coatings. They can improve the production efficiency of antireflection coatings, optimize product performance, promote the development of antireflection coating technology, and expand the application fields of antireflection coatings. With the continuous advancement of science and technology and the continuous development of laboratory coating machine technology, it is believed that the application of laboratory coating machines in the preparation of anti-reflection coatings will be further expanded and deepened, providing more reliable development and application of optical technology. support.

- 1Application of laboratory coater in LED fluorescent film Spreader

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 4Application of doctor blade coater in electrode and solid electrolysis preparation

- 5Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 6Experimental application of water-based paints on film laminating paper by laboratory coater

- 7Experimental coater application case video of liquid silica gel on release paper

- 8Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 9Application of small coater in gel coating