Application of small experimental coater in the preparation of polarizing film

Abstract: This article will discuss the application of small experimental coating machines in the preparation of polarizing films. As a functional film with special optical properties, polarizing film is widely used in liquid crystal displays, glasses, photography lenses and other fields. However, the traditional polarizing film preparation process usually requires expensive equipment and complex processes, limiting its application in laboratories and small-scale production. As a simple and economical preparation tool, the small experimental coating machine provides new possibilities for the research and development of polarizing films. Through an in-depth analysis of the principles, characteristics and application of small experimental coating machines in polarizing film preparation, this article aims to provide technical reference and guidance for relevant researchers.

Keywords: small experimental coating machine, polarizing film, preparation process, application research

introduction

Polarizing film is a thin film material with special optical properties that can effectively adjust the direction of light propagation and has broad application prospects. In fields such as LCD displays, glasses, and photography lenses, polarizing films can improve the contrast of products, reduce glare, and improve visual effects. However, traditional polarizing film preparation processes usually require expensive equipment and complex processes, limiting their application in laboratories and small-scale production. For this reason, it is of great significance to develop a simple and economical polarizing film preparation tool.

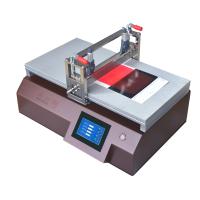

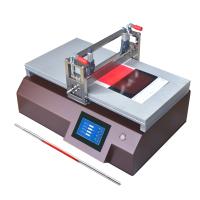

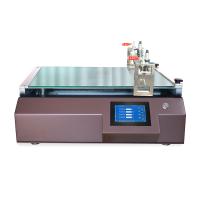

Principles and characteristics of small experimental coating machine

The small experimental coating machine is a device that uses coating technology to achieve small-scale coating of thin film materials. Its main principle includes coating system, transmission system, control system and other parts. Through precise control of coating thickness, speed, temperature and other parameters, uniform coating of the film is achieved.

The small experimental coating machine has the following significant features:

Easy to use: Small experimental coating machines usually have a simple structure and are easy to operate. They do not require complex operating skills and a lot of manpower investment.

Flexibility: Small experimental coating machines usually have a variety of coating modes and coating material adaptability, which can meet different experimental needs.

Economical and efficient: Compared with traditional large-scale coating equipment, small experimental coating machines are lower in cost and suitable for laboratories and small-scale production.

Application of small experimental coating machine in polarizing film preparation

In the preparation process of polarizing films, small experimental coating machines play an important role. Its application is mainly reflected in the following aspects:

3.1 Material coating. The small experimental coating machine can evenly coat the materials required for the polarizing film on the substrate to form a thin film. By adjusting the coating parameters, the thickness and optical properties of the polarizing film can be controlled to meet different experimental needs.

3.2 Process optimization. The small experimental coating machine can be used to optimize and adjust the polarizing film preparation process. By adjusting coating speed, temperature, pressure and other parameters, the polarizing film preparation process can be optimized and product quality and performance improved.

3.3 Experimental research. The small experimental coating machine provides scientific researchers with a convenient experimental platform for research and exploration of polarizing film preparation processes. Through experimental research, we can gain an in-depth understanding of the preparation mechanism of polarizing films and guide product optimization and improvement.

Case analysis of small experimental coating machine in polarizing film preparation

In order to better demonstrate the application effect of small experimental coating machines in polarizing film preparation, the following is a case analysis using a research team as an example:

A research team successfully prepared a new polarizing film material using a small experimental coating machine and conducted a systematic study on its optical properties. By optimizing and adjusting the coating parameters, they successfully controlled the thickness and optical properties of the polarizing film, achieving adjustment and optimization of the polarizing effect. This research result provides important technical support for the development and application of new polarizing film materials.

in conclusion

As a simple and economical polarizing film preparation tool, the small experimental coating machine has important application value in the research and development of polarizing films.

- 1Application of laboratory coater in LED fluorescent film Spreader

- 2Application and selection of laboratory coater in PDMS thin film prepative

- 3Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 4Application of doctor blade coater in electrode and solid electrolysis preparation

- 5Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 6Experimental coater application case video of liquid silica gel on release paper

- 7Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane

- 8Several Common Experimental Spreader Methods and Their Applications

- 9Application of laboratory coater coating aluminum oxide paste on PET film