Application and Selection of Laboratory Film Applicator in TAC Film

Abstract: This article will discuss the application of laboratory coating machines in the preparation process of TAC (Tri-Acetyl Cellulose) membranes, and introduce the key factors that need to be considered when selecting. TAC film is a common optical material that has the advantages of high transparency, excellent chemical resistance and mechanical properties, and is therefore widely used in optics, electronics, medical and other fields. As a key equipment for TAC film preparation, the selection of laboratory Film Applicator directly affects the quality and performance of the film. Therefore, various technical indicators and actual needs need to be carefully considered.

1. Introduction 1.1 Characteristics and application fields of TAC membrane

1.2 The role and importance of laboratory coating machines in TAC film preparation

2. Basic principles and working procedures of laboratory film coating machines

2.1 Principles of coating technology

2.2 Main components of laboratory coating machine

2.3 Work flow and operating steps

3. Key technical points of laboratory coating machine in TAC film preparation

3.1 Coating thickness control

3.2 Temperature and humidity control

3.3 Membrane material selection

3.4 Coating uniformity

4. Laboratory coating machine selection guide

4.1 Equipment specifications and performance parameters

4.2 Cost considerations

4.3 Brand reputation and after-sales service

4.4 Laboratory needs and future scalability

5. Case analysis and practical experience sharing

5.1 Summary of a laboratoryâs experience in using a laboratory coating machine to prepare TAC film

5.2 Comparison of different types of laboratory coating machines in TAC film preparation

6. Conclusion and outlook

6.1 The importance and application prospects of laboratory coating machines in TAC film preparation

6.2 Future development direction and technology trends

Keywords: Laboratory coating machine, TAC film, coating technology, selection guide, workflow

1. Introduction

1.1 Characteristics and application fields of TAC membrane

TAC film is a transparent film made of triacetyl cellulose. It has excellent optical properties and chemical stability and is commonly used in optical lenses, LCD panels, medical lenses and other fields. Its high transparency, low dispersion and excellent mechanical properties make it one of the ideal materials for many high-end optical products.

1.2 The role and importance of laboratory coating machines in TAC film preparation

The laboratory film coating machine is a special equipment used to coat thin film materials on the surface of substrates. By controlling parameters such as coating thickness, temperature and humidity, precise control of film quality is achieved. In the preparation process of TAC membrane, the laboratory coating machine plays a vital role, and its performance and stability directly affect the quality and performance of the membrane.

2. Basic principles and working procedures of laboratory film coating machines

2.1 Principles of coating technology

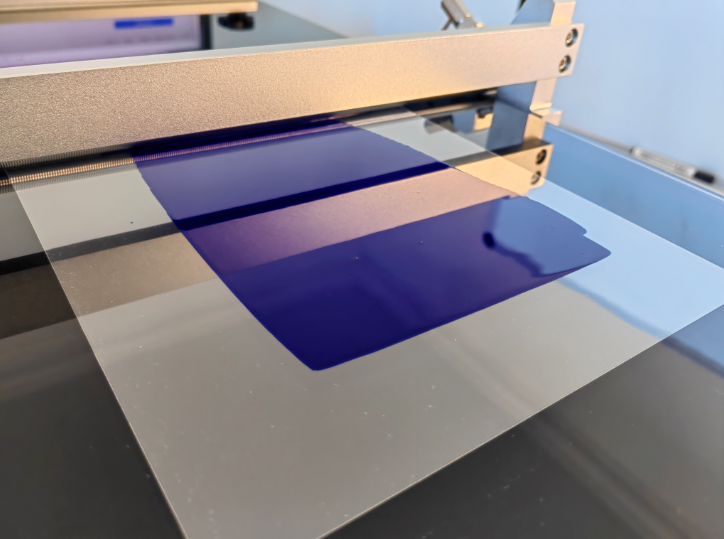

Laboratory coating machines use coating technology to form a uniform coating on the surface of the substrate. Coating technology mainly includes roller coating, scraping coating, spray coating and other methods, among which roller coating and scraping coating are commonly used coating methods. The coating machine controls the coating thickness and uniformity by controlling parameters such as coating thickness, coating speed, and coating pressure.

2.2 Main components of laboratory coating machine

The laboratory film coating machine is mainly composed of a coating unit, a control system, a conveying system and other parts. The coating unit includes a coating head, roller, etc., which is used to evenly coat the coating on the surface of the substrate; the control system is used to adjust coating parameters, such as temperature, humidity, coating thickness, etc.; the conveying system is used to The substrate is transported to the coating unit and the coating speed is controlled.

2.3 Work flow and operating steps

The workflow of the laboratory coating machine mainly includes steps such as substrate preparation, coating debugging, coating processing, drying and curing. During the operation, the coating parameters need to be accurately adjusted according to the characteristics of the coating material and process requirements, and the coating process should be monitored and adjusted in real time to ensure the stability of coating quality and performance.

3. Key technical points of laboratory coating machine in TAC film preparation

3.1 Coating thickness control

Coating thickness is one of the key factors affecting film quality. A coating that is too thick or too thin will affect the optical and mechanical properties of the film. Therefore, laboratory coating machines need to have precise coating thickness control capabilities, and pressure sensors, optical Thickness Gauges and other equipment are usually used for online monitoring and adjustment.

3.2 Temperature control

Temperature has an important impact on the coating process and coating performance. Too high or too low temperature will lead to problems such as uneven drying of the coating and incomplete crystallization. Therefore, the laboratory coating machine needs to have a good temperature control system to ensure that the coating process is carried out under suitable environmental conditions.

3.3 Membrane material selection

The choice of coating materials directly affects the performance and application range of the membrane. Different coating materials have different characteristics and applicable fields. When selecting membrane materials, factors such as their optical properties, mechanical properties, and chemical stability need to be considered, and reasonable selections should be made based on specific needs.

3.4 Coating uniformity

Coating uniformity is one of the important indicators to measure coating quality. Uneven coating will cause defects such as spots and bubbles on the film surface, affecting the optical transparency and uniformity of the film. Therefore, effective measures need to be taken during the coating process to ensure the uniformity and stability of the coating.

4. Laboratory coating machine selection guide

4.1 Equipment specifications and performance parameters

During the selection process, appropriate equipment specifications and performance parameters need to be selected based on actual needs and budget. Common specification parameters include coating width, coating speed, coating thickness range, etc. Performance parameters include coating accuracy, temperature and humidity stability, coating uniformity, etc.

4.2 Cost considerations

The prices of laboratory Film Applicators vary greatly, and cost issues need to be considered based on the laboratory budget and long-term investment. In addition to the price of the equipment itself, factors such as equipment operation and maintenance costs and consumable costs also need to be considered.

4.3 Brand reputation and after-sales service

Choosing equipment from well-known brands can reduce the risk of later maintenance and repairs, and at the same time, you can get better after-sales service guarantee. Therefore, the brand reputation and after-sales service level of the equipment manufacturer need to be comprehensively considered during the selection process.

4.4 Laboratory needs and future scalability

During the selection process, it is necessary to fully consider the actual needs and future development direction of the laboratory, and select equipment with good scalability and flexibility. At the same time, the use environment and site conditions of the equipment need to be considered to ensure that the equipment can be put into use smoothly.

5. Case analysis and practical experience sharing

5.1 Summary of a laboratoryâs experience in using a laboratory coating machine to prepare TAC film

A certain laboratory used a certain brand of laboratory coating machine to successfully prepare high-quality TAC films by precisely controlling coating parameters and process flow. After long-term practice, a set of effective coating processes and quality control plans have been summarized, which provides strong support for laboratory research work.

5.2 Comparison of different types of laboratory coating machines in TAC film preparation

Comparative analysis of the performance parameters, coating processes and costs of different types of laboratory coating machines can help laboratories choose the most suitable equipment. Different types of film coating machines have their own advantages and disadvantages, which need to be comprehensively considered based on actual needs.

6. Conclusion and outlook

6.1 The importance and application prospects of laboratory coating machines in TAC film preparation

As the key equipment for TAC film preparation, the performance and stability of the laboratory Film Applicator directly affect the quality and performance of the film. With the continuous development of optics, electronics, medical and other fields, the application prospects of laboratory coating machines in TAC film preparation are very broad.

6.2 Future development direction and technology trends

In the future, with the continuous innovation of coating technology and the continuous improvement of coating machine equipment, laboratory coating machines will be more intelligent and automated, with higher production efficiency and coating quality, making TAC film preparation more convenient. and reliable solutions.

In summary, laboratory film coating machines have important application value and development potential in TAC film preparation. Choosing appropriate equipment and scientific process flow are the key to ensuring film quality and performance. It is hoped that this article can provide reference and reference for researchers in related fields and promote the further development and application of laboratory coating technology.

- 1How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 2NVP anode film FAQ and solution

- 3Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 4Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 5Application and selection of laboratory coater in PDMS thin film prepative

- 6Scraping machine selection case: film substrate large size high accuracy scraping solution

- 7Application of Laboratory Automatic Film Applicator in Coating Battery Slurry on Copper Foil and Aluminum Foil

- 8Application of Film Applicator in PEM Research and Preparation

- 9Application of Film Applicator in PVDF-HFP Material Research