Why Do Film Applicators Need to Change Their Wires Regularly?

Do you regularly replace the wire Bar Coater of the automatic film coating machine you use?

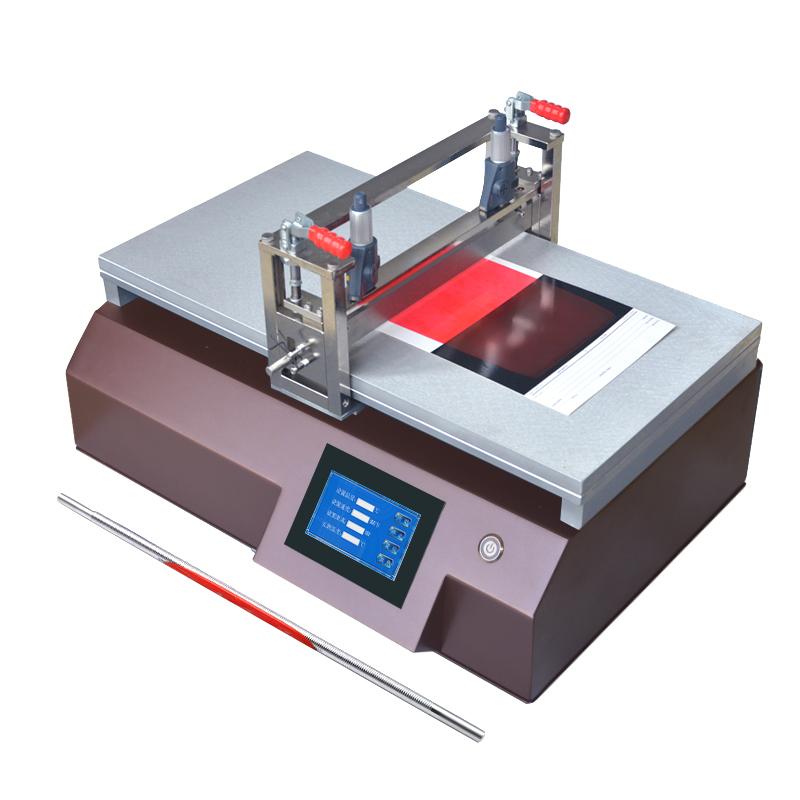

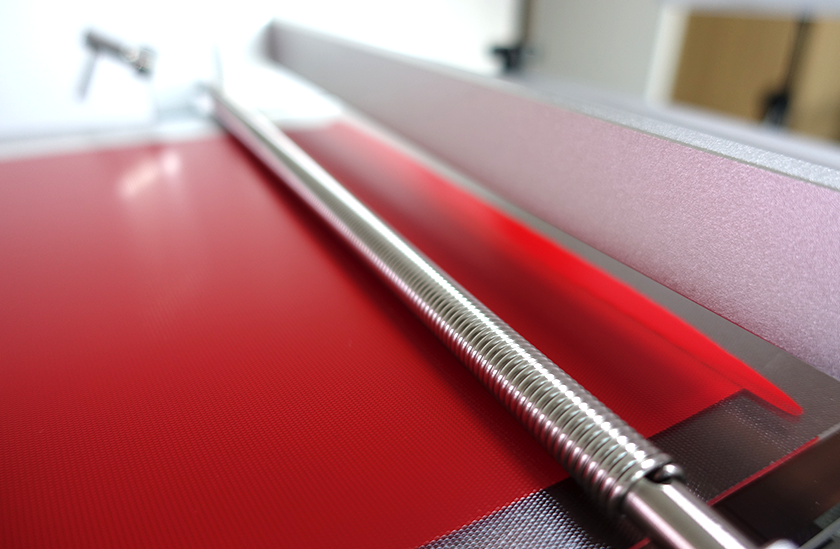

The laboratory coating machine replaces manual coating to realize automatic coating, which not only improves the coating efficiency, but also further improves the accuracy of the coating through constant speed and constant pressure. Anyone who uses automatic coating machine technology knows that the wire Bar Coater is a key component of the experimental coating machine. It is responsible for evenly coating the coating on the surface of the substrate. It mainly controls the thickness and accuracy of the coating film.

However, any item has an aging process, and the wire rod coater as a consumable is no exception. It has long-term scraping and contact with various materials, such as substrates with different roughness, corrosive chemicals, etc. Materials etc. In the long-term use process, the accuracy of the wire rod will be more or less affected. Taking wire-wound rods as an example, long-term scraping and proofing causes the wire-wound rods to wear and age, causing the actual coating film thickness to become smaller.

So, what are the benefits of regularly replacing the wire rods of the film coating machine?

1. Ensure stable coating quality: As the wire rod wears or corrodes, on the one hand, the thickness of the coating will become smaller. On the other hand, if cleaning is not done properly , the surface may be uneven or contaminated, resulting in poor quality of the coating. decline, resulting in problems such as poor uniformity and reduced accuracy. Regular replacement of wire rods can ensure that the applicator is always in good condition and ensures stable quality of the coating layer.

2. Ensure the accuracy of experimental results: Laboratory research and development often require highly accurate data and results. Unstable coating quality may lead to data errors and affect the credibility of research conclusions. Regular replacement of wire rods helps ensure accuracy and repeatability of experimental results.

Therefore, truly professional technology can see the essence and regularly replace the wire Bar Coater to ensure the quality and precision of the coating film and the accuracy of the experimental results.

- 1Application of Mayer Rods in protective coating prepative

- 2How Flat Film Applicators Can Build a New Generation of Functional Materials on Fabrics

- 3NVP anode film FAQ and solution

- 4Application Technology of Laboratory Film Applicator in Dielectric Thin Film

- 5Comparison of Advantages and Disadvantages of Three Heating modes for Laboratory Film Applicators

- 6Application and selection of laboratory coater in PDMS thin film prepative

- 7Scraping machine selection case: film substrate large size high accuracy scraping solution

- 8Application of Laboratory Automatic Film Applicator in Coating Battery Slurry on Copper Foil and Aluminum Foil

- 9Application of Film Applicator in PEM Research and Preparation