Optical inspection of transparent adhesive (OCA) film with small test coater

Abstract: This article explores the application of a small experimental coater in the study of optically clear adhesive (OCA) films. First, the basic characteristics of OCA and its importance in electronic product manufacturing are introduced, and then the structure and working principle of the small test coating machine are described in detail. Next, the advantages and application scenarios of the small experimental coater in OCA film research are explained, including the flexibility of film preparation and the convenience of laboratory research. Finally, the development prospects of small experimental coating machines in the future research field of optically transparent adhesive films are prospected.

introduction

Optically clear adhesive (OCA), as an important adhesive material, plays a key role in the manufacturing of electronic products. Its excellent optical properties and adhesive properties make it widely used in the assembly of electronic products such as LCD displays and touch screens. In the research and development process of OCA, it is of great significance to conduct in-depth exploration of the preparation and properties of its films. As a tool suitable for laboratory research, the small test coater provides convenient conditions for OCA film research.

Basic characteristics and applications of optically clear adhesive (OCA)

Optically Clear Adhesive (OCA) is a special type of adhesive with a unique set of properties that make it widely used in many fields. The following are the basic characteristics and applications of optically clear glue:

High transparency : OCA has excellent transparency and can maintain the clarity and transparency of the material surface without causing obvious scattering or diffraction effects on light. This makes it ideal for applications where high definition and optical performance need to be maintained, such as screen assembly for electronic products such as LCD displays, flat-panel TVs and smartphones.

Good adhesion properties : OCA has excellent adhesion properties and can firmly bond surfaces between different materials, such as glass, metal, plastic, etc. This makes it a key material in electronics assembly, ensuring strong connections between various components.

Excellent optical properties : In addition to high transparency, OCA also has excellent optical properties, such as low refractive index, low dispersion and other characteristics, which can effectively reduce reflection and scattering on the surface of optical devices and improve the performance and reliability of optical systems.

Weather resistance : OCA has good weather resistance and chemical stability, can maintain stable adhesion and optical properties under various environmental conditions, and is not easily affected by factors such as temperature, humidity, ultraviolet rays, etc.

Application fields: Optical transparent adhesive is widely used in electronic products, optical devices, medical equipment and other fields. In electronic products, it is mainly used in the assembly of LCD screens, touch screens, flat-panel TVs, smartphones and other devices to achieve bonding between screens and other components. In optical devices, OCA is used for the assembly and fixation of optical lenses, lenses, optical filters and other components. In the field of medical equipment, OCA is widely used in the assembly and repair of medical equipment, such as medical microscopes, optical instruments, etc.

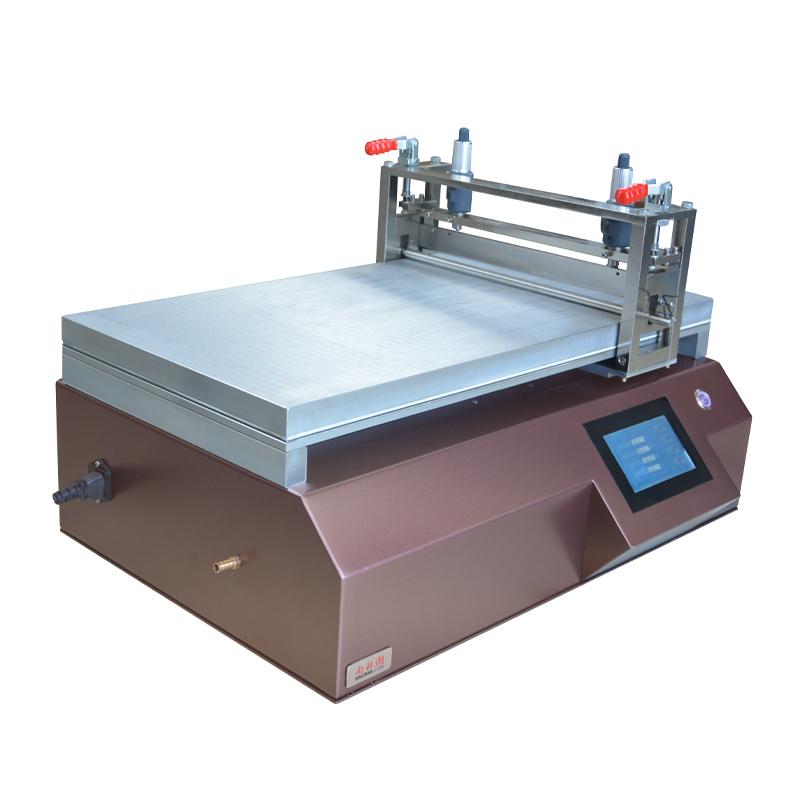

Structure and working principle of small test coating machine

A small pilot coater is a device used for laboratory research, usually with a compact structure and flexible operation. It mainly consists of coating head, feeding system, control system, etc. During operation, the position and coating thickness of the coating head are adjusted through the control system, and the OCA solution is evenly coated on the surface of the substrate to form a uniform and stable film.

Application of small experimental coater in OCA film research

Small experimental coating machines have important application value in OCA film research. First, it can provide convenient conditions for laboratory research and achieve precise control and adjustment of the OCA film preparation process. Secondly, due to its flexibility and efficiency, it can meet different experimental needs, such as adjusting and optimizing parameters such as coating thickness and speed to study its impact on film properties. In addition, the small experimental coating machine can also be used to prepare composite films of different materials to explore its application potential in electronic products.

Prospects

With the continuous advancement of science and technology and the deepening of laboratory research, the application prospects of small experimental coating machines in the field of optically clear adhesive (OCA) film research are very broad. In the future, we can foresee that with the continuous optimization and improvement of OCA film preparation technology, small test coating machines will play an increasingly important role, providing more reliable technical support for the application of OCA in the field of electronic products.

In short, small experimental coaters play an important role in the research of optically clear adhesive (OCA) films, providing convenient conditions for laboratory research and promoting the development of related fields. Looking forward to the future, with the continuous innovation of technology and the expansion of applications, small experimental coating machines will show broader application prospects in the field of OCA thin film research.

- 1Application and selection of laboratory coater in PDMS thin film prepative

- 2Experimental Study on High Viscosity Ultraviolet Resin Coating on Glass Substrate by Small Coater

- 3Application of doctor blade coater in electrode and solid electrolysis preparation

- 4Application case of Bar Coater coating slurry on small workpiece ceramic substrate [Experimental video demonstration]

- 5Experimental application of water-based paints on film laminating paper by laboratory coater

- 6Laboratory small coater coated with polyester film on ultra-thin PET film [video demonstration]

- 7Technical Requirements and Application of Lithium Battery Slurry Coated on Copper Foil for Small Coater

- 8Application of small coater in gel coating

- 9Laboratory Technology and Application of Polyvinyl Alcohol Film Coating on Ultrafiltration Membrane