The working principle and application of eddy current Flaw Detector

With the continuous development of industrial manufacturing technology, the application range of various materials is becoming wider and wider, which also brings higher requirements for material quality and safety. During the production, processing and use of materials, various defects and damage may occur, and these problems will have an adverse impact on the performance and life of the materials. Therefore, it is particularly important to develop efficient and accurate non-destructive testing technology. As an important non-destructive testing equipment, the finned tube eddy current flaw Detector plays an important role in aerospace, automobile manufacturing, nuclear power and other fields. This article will deeply explore the principles, application fields and future development directions of finned tube eddy current flaw Detectors.

working principle

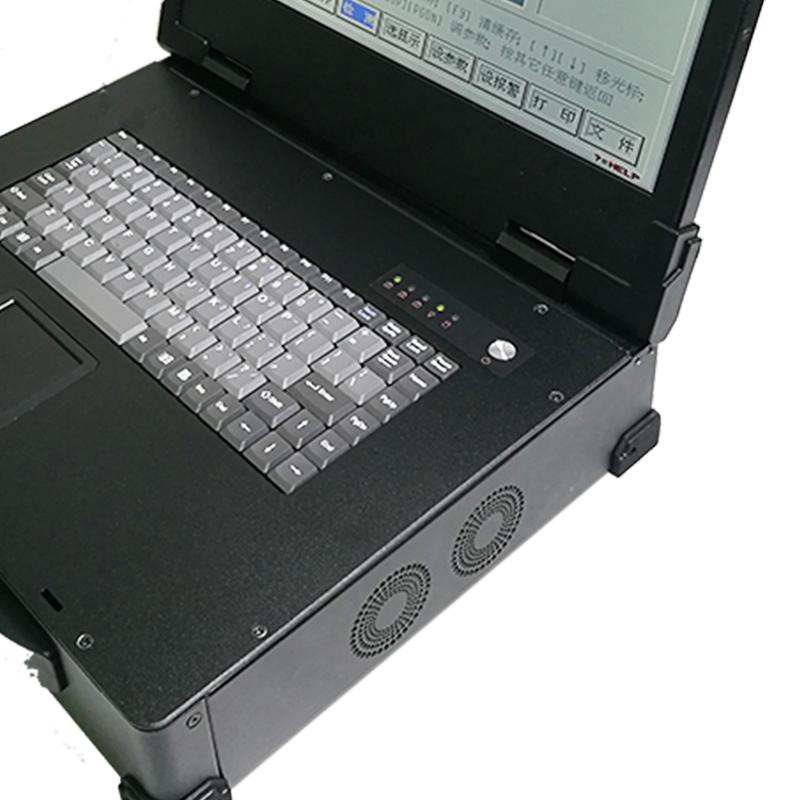

The finned tube eddy current flaw Detector is a device that uses the eddy current principle for non-destructive testing. The device uses the principle of electromagnetic induction to generate an alternating magnetic field on the surface of the finned tube, thereby generating eddy currents in the tube. When the eddy current encounters defects or foreign objects on the pipe wall, an eddy current induction effect occurs, causing the eddy current field to change. The device detects changes in eddy current induction signals through Detectors and converts the signals into electrical signal output. The detected signals are analyzed and processed, and defects inside the pipeline are judged through signal changes.

Application areas

Fin tube eddy current flaw Detectors are widely used in the following fields. In the aerospace field, it is used for non-destructive testing of pipelines of key components such as aircraft engines and gas turbines to ensure their safety and reliability. In the field of automobile manufacturing, it is used for non-destructive testing of pipelines of key components such as automobile engines and gearboxes to improve the quality and safety of automobiles. In the nuclear power industry, it is used for non-destructive testing of the pipeline to ensure the safe operation of nuclear power plants. In the field of petrochemical industry, it is used for non-destructive testing of oil pipelines, chemical pipelines, etc. to prevent leaks and accidents.

In the future, with technological innovation, the sensitivity, accuracy and detection speed of the equipment will be further improved, and more advanced detection technology and signal processing algorithms will be developed. The equipment will be more intelligent, with functions such as automation and remote control, improving operational convenience and work efficiency. It will have more functional modules, such as multi-channel detection, multi-angle detection, etc., to meet the needs of different application fields.

As an efficient and accurate non-destructive testing equipment, the finned tube eddy current flaw Detector plays an important role in aerospace, automobile manufacturing, nuclear power and other fields. It has the advantages of high sensitivity, high precision, rapid detection, non-destructiveness, and strong adaptability, and provides reliable technical guarantee for the safe operation of various pipelines. With the continuous advancement of science and technology and the increasing demand for applications, finned tube eddy current flaw Detectors will continue to innovate and develop, making greater contributions to the progress and development of human society.

- 1Basic Principle Characteristics and Application Analysis of Flaw Detector for Casting

- 2Application of Ultrasonic Flaw Detector in Weld Flaw Detection

- 3Ultrasonic flaw detection defect judgment

珀泰@sisi

- 4Will the environment temperature cause errors in flaw detection?

- 5Ultrasonic flaw detection FAQ answer summary

- 6Working Principle and Measurement Characteristics of Eddy Current Flaw Detector

王雄飞;范冬娟;王琴 - 《中国高新技术企业》