Application of Glue Spreader on Polyimide Film

Summary:

With the continuous advancement of science and technology and the development of manufacturing industry, various new materials are used more and more widely, and polyimide film, as an advanced functional material with excellent performance, is widely used in electronics, aerospace, medical and other fields. However, the application of polyimide film often requires combination with other materials, and glue coating is an important part of it. This article will introduce the application of a small glue applicator to apply glue on polyimide film and discuss its importance and advantages in the manufacturing industry.

I. Introduction

Polyimide films are widely used in various fields due to their excellent properties, such as high temperature stability, chemical inertness, mechanical strength, etc. However, pure polyimide films often cannot meet actual needs and need to be combined with other materials to achieve specific functions. In this case, gluing becomes a common method to bond polyimide films with other materials by applying glue to achieve specific engineering requirements.

2. Characteristics and advantages of small glue applicators

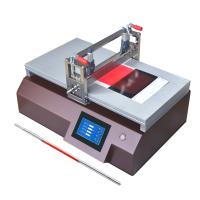

A small glue applicator is a device used to evenly apply glue on the surface of a film. Compared with the traditional glue coating process, it has the following features and advantages:

Flexibility: The small glue applicator is compact in size, simple in structure, and flexible in operation. It is suitable for films of various specifications and shapes.

High degree of automation: The small glue coating machine adopts an advanced automation control system, which can realize the automatic operation of the glue coating process and improve production efficiency.

High glue coating uniformity: The small glue coating machine is equipped with a precision glue coating head, which can evenly apply glue on the film surface to ensure the glue coating quality.

Save raw materials: The small glue coating machine adopts precise glue coating control technology, which can effectively save the usage of glue and reduce production costs.

Environmental protection and energy saving: The small glue applicator adopts advanced technology, which can realize the recycling of glue, reduce waste liquid discharge, and meet environmental protection requirements.

3. Application case of small glue applicator applying glue on polyimide film

Taking the electronics industry as an example, polyimide films are increasingly used in electronic devices. When manufacturing electronic devices, it is often necessary to bond polyimide films with materials such as metal and glass to achieve electrical connection or protection. The small glue applicator plays an important role in this process.

Take an electronics company as an example. They use a small glue applicator to bond polyimide films and metal substrates together to manufacture flexible circuit boards. During the production process, the small glue applicator ensures the bonding quality between the polyimide film and the metal substrate through precise glue application control technology, while improving production efficiency. Compared with traditional manual gluing, the small gluing machine can not only realize automated operation, reduce labor costs, but also have higher gluing uniformity, improving product quality and stability.

4. Development Trend of Small Glue Coating Machines

With the continuous development of science and technology, the application of small glue applicators in applying glue on polyimide films will become more and more widespread. In the future, as the level of intelligence and automation in the manufacturing industry increases, small gluing machines will become more intelligent, and gluing quality and production efficiency will be further improved. At the same time, with the increasing awareness of environmental protection, small gluing machines will pay more attention to energy conservation and emission reduction, adopt more environmentally friendly gluing technology, and make greater contributions to the sustainable development of the manufacturing industry.

5. Conclusion

The application of small gluing machines to apply glue on polyimide films is of great significance. It can not only improve the quality of gluing and production efficiency, but also reduce production costs and meet the development needs of modern manufacturing. With the continuous advancement of technology, small glue applicators will play a more important role in various fields and promote the intelligent, automated and sustainable development of the manufacturing industry.

- 1Glue spreader technical guide on Resin

- 2Water-based Pressure sensitive adhesive coating machine selection technical guide

- 3Working Principle and Application of PE Protective Film Coating Machine